HEADLIGHT ASSEMBLY(for ALPHARD) REASSEMBLY

CAUTION / NOTICE / HINT

Note

-

Handle components indoors as much as possible to prevent foreign matter from entering and adhering to headlight assembly components.

-

Do not reuse parts which have reduced fastening ability due to thread damage.

-

Do not touch the inner surface of the lens and metallic surfaces as much as possible, or they may become dirty.

-

Do not allow metallic surfaces to become dirty, as such surfaces become damaged even if they are only lightly wiped with a soft cloth.

-

When installing components, make sure that the wire harness is not pinched or pulled.

-

Do not use solvent to clean components. Only clean them with a dry cloth.

Tech Tips

-

Use the same procedure for the RH and LH sides.

-

The procedure listed below is for the LH side.

PROCEDURE

-

INSTALL HEADLIGHT LED UNIT ASSEMBLY LH

Note

-

Prevention of static electricity is required during this procedure.

-

Use static electricity countermeasures SST (desktop antistatic mat set) and observe all precautions to prevent damage to the system by electrostatic discharge (ESD).

-

Perform work using clean rubber gloves.

-

Do not touch the headlight LED unit assembly LH with bare hands.

-

Do not allow metallic surfaces to become dirty, as such surfaces become damaged even if they are only lightly wipe with a soft cloth.

-

If there are fingerprints on the inner surface of the lens, lightly wiped with a soft cloth.

-

Do not use solvent to clean components. Only clean them with a dry cloth.

- SST

- 09890-47010 ( 09891-04020, 09891-04010, 09891-04030, 09891-04040 )

-

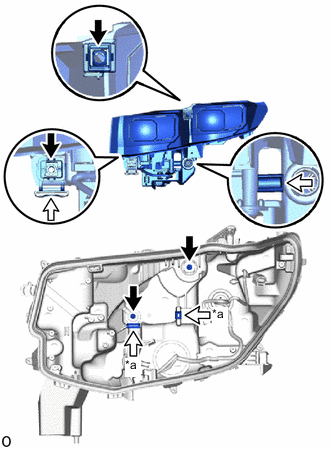

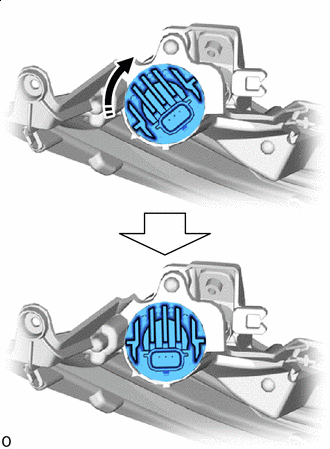

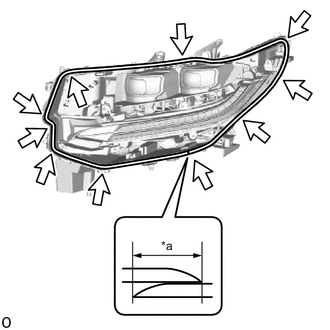

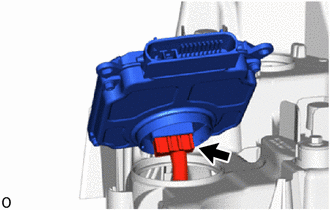

*a Rail Set the headlight LED unit assembly LH onto the left and right rails and aiming screws for beam axis vertical and horizontal adjustments.

Tech Tips

Set it into place by aligning the arrows shown in the illustration: black with black, and white with white.

-

Clockwise Hold the headlight LED unit assembly LH with one hand to prevent it from tipping over and tighten the aiming screws for beam axis horizontal and vertical adjustments clockwise with the number of turns that were recorded.

-

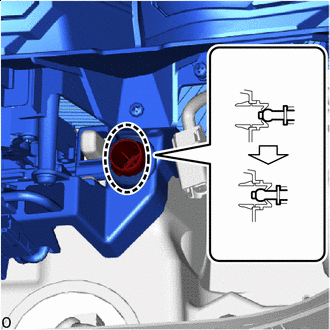

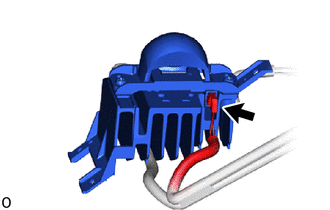

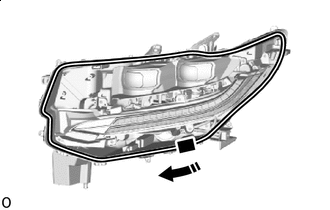

Push Here Push the part shown in the illustration to connect the pivot collar.

-

Clockwise Tighten the aiming screws for beam axis horizontal and vertical adjustments by rotating them clockwise 10 times each.

-

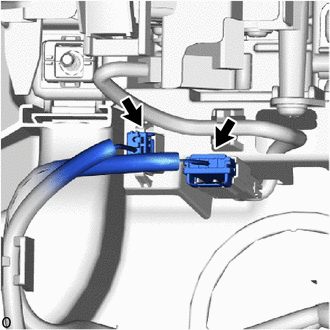

Connect the 2 connectors.

-

-

INSTALL HEADLIGHT CORNERING LED UNIT LH (w/ Cornering Light)

Note

-

Prevention of static electricity is required during this procedure.

-

Use static electricity countermeasures SST (desktop antistatic mat set) and observe all precautions to prevent damage to the system by electrostatic discharge (ESD).

-

Perform work using clean rubber gloves.

-

Do not touch the headlight cornering LED unit LH and headlight LED unit assembly LH with bare hands.

-

Do not allow metallic surfaces to become dirty, as such surfaces become damaged even if they are only lightly wipe with a soft cloth.

-

If there are fingerprints on the inner surface of the lens, lightly wiped with a soft cloth.

-

Do not use solvent to clean components. Only clean them with a dry cloth.

- SST

- 09890-47010 ( 09891-04020, 09891-04010, 09891-04030, 09891-04040 )

-

Connect the connector.

-

Install the headlight cornering LED unit LH with the 3 screws.

-

Install the cornering light unit bezel with the 2 screws.

-

-

INSTALL HEADLIGHT CLEARANCE LED SOCKET (w/o Cornering Light)

Note

-

Prevention of static electricity is required during this procedure.

-

Use static electricity countermeasures SST (desktop antistatic mat set) and observe all precautions to prevent damage to the system by electrostatic discharge (ESD).

-

Perform work using clean rubber gloves.

-

Do not touch the light emitting part on the headlight clearance LED unit LH and headlight clearance LED socket with bare hands.

-

Do not allow metallic surfaces to become dirty, as such surfaces become damaged even if they are only lightly wiped with a soft cloth.

-

If there are fingerprints on the inner surface of the lens, lightly wipe with a soft cloth.

-

Do not use solvent to clean components. Only clean them with a dry cloth.

- SST

- 09890-47010 ( 09891-04010, 09891-04020, 09891-04030, 09891-04040 )

-

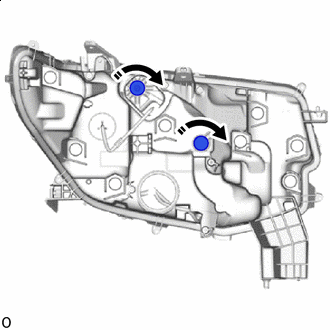

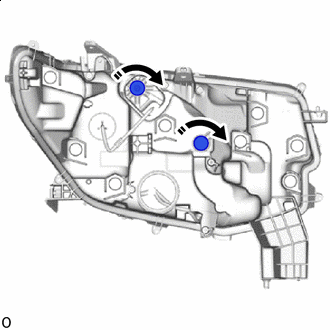

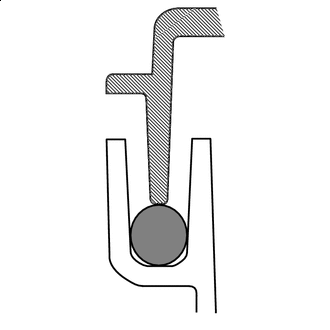

Clockwise Set the headlight clearance LED socket into place and turn the headlight clearance LED socket until it stops to install it.

-

-

INSTALL HEADLIGHT TURN SIGNAL LED SOCKET (w/o Cornering Light)

Note

-

Prevention of static electricity is required during this procedure.

-

Use static electricity countermeasures SST (desktop antistatic mat set) and observe all precautions to prevent damage to the system by electrostatic discharge (ESD).

-

Perform work using clean rubber gloves.

-

Do not touch the light emitting part on the headlight clearance LED unit LH and headlight turn signal LED socket with bare hands.

-

Do not allow metallic surfaces to become dirty, as such surfaces become damaged even if they are only lightly wiped with a soft cloth.

-

If there are fingerprints on the inner surface of the lens, lightly wipe with a soft cloth.

-

Do not use solvent to clean components. Only clean them with a dry cloth.

- SST

- 09890-47010 ( 09891-04010, 09891-04020, 09891-04030, 09891-04040 )

Tech Tips

Use the same procedure to install the headlight clearance LED socket.

-

-

INSTALL HEADLIGHT CLEARANCE LED UNIT LH

Note

-

Prevention of static electricity is required during this procedure.

-

Use static electricity countermeasures SST (desktop antistatic mat set) and observe all precautions to prevent damage to the system by electrostatic discharge (ESD).

-

Perform work using clean rubber gloves.

-

Do not touch the No. 1 headlight clearance LED unit LH with bare hands.

-

Do not allow metallic surfaces to become dirty, as such surfaces become damaged even if they are only lightly wipe with a soft cloth.

-

If there are fingerprints on the inner surface of the lens, lightly wipe with a soft cloth.

-

Do not use solvent to clean components. Only clean them with a dry cloth.

- SST

- 09890-47010 ( 09891-04020, 09891-04010, 09891-04030, 09891-04040 )

-

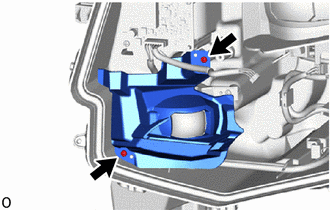

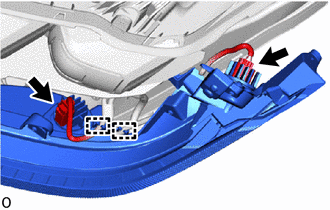

w/o Cornering Light:

-

Connect the 2 connectors and attach the wire harness clamp.

-

Install the No. 1 headlight clearance LED unit LH with the 4 screws.

-

-

w/ Cornering Light:

-

Install the No. 1 headlight clearance LED unit LH with the 3 screws.

-

Connect the 2 connectors and attach the wire harness clamp.

Screw

Connector

-

-

-

INSTALL HEADLIGHT LENS GASKET

Note

-

The headlight lens gasket must not be reused.

-

Perform work using clean rubber gloves.

-

Do not touch the inner surface of the lens and metallic surfaces as much as possible, or they may become dirty.

-

Do not allow metallic surfaces to become dirty, as such surfaces become damaged even if they are only lightly wiped with a soft cloth.

-

If there are fingerprints on the inner surface of the lens, lightly wipe with a soft cloth.

-

Do not use solvent to clean components. Only clean them with a dry cloth.

-

Area to Clean Clean the headlight lens gasket installation groove.

-

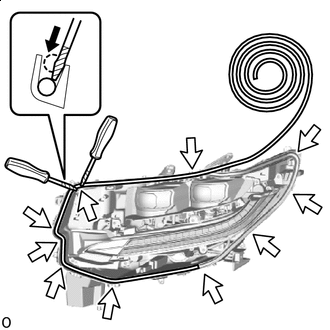

Prepare 2 screwdrivers, fold a piece of peeling paper over the tip of each screwdriver and fix the pieces of peeling paper in place with tape.

Tech Tips

Use the peeling paper that is supplied with the headlight lens gasket.

-

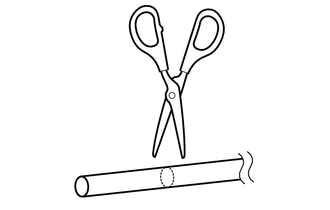

Using scissors, cut the headlight lens gasket at a 90°.

-

Starting Point

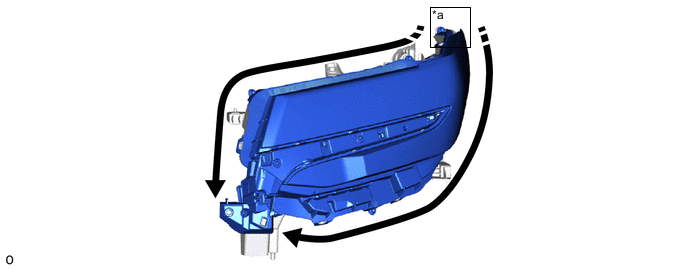

Clockwise Starting from the position shown in the illustration, set the headlight lens gasket into the straight groove clockwise until it meets the corner groove.

Note

Lightly set the gasket in place without pulling.

-

Fold the peeling paper over the tip of a screwdriver and fix it in place with tape.

Note

Use the peeling paper that is supplied with the seal.

-

Corner Groove

Headlight Lens Gasket

Peeling Paper Set the headlight lens gasket into the corner groove and using 2 screwdrivers with their tips wrapped with peeling paper, push the gasket into the bottom of the groove.

Note

-

Lightly set the gasket in place without pulling.

-

If the headlight lens gasket is set while pulled, the gasket will be pushed up at the corner groove.

-

-

Repeat the following order while working in a circle back to the starting point.

-

Set headlight lens gasket into straight groove.

-

Push into bottom of groove.

-

Set into corner groove.

-

Push into bottom of groove.

-

-

*a 20 mm (0.7874 in.)

Corner Groove Using scissors, cut the headlight lens gasket at a 45° angle at the starting point so that the gasket overlaps itself 20 mm (0.7874 in.) and set the gasket in place.

-

Check the installation condition of the headlight lens gasket.

OK Gasket not pushed up or protruding. No gap where gasket overlaps. Note

Check the corners carefully since the gasket can easily become pushed up in those areas.

-

-

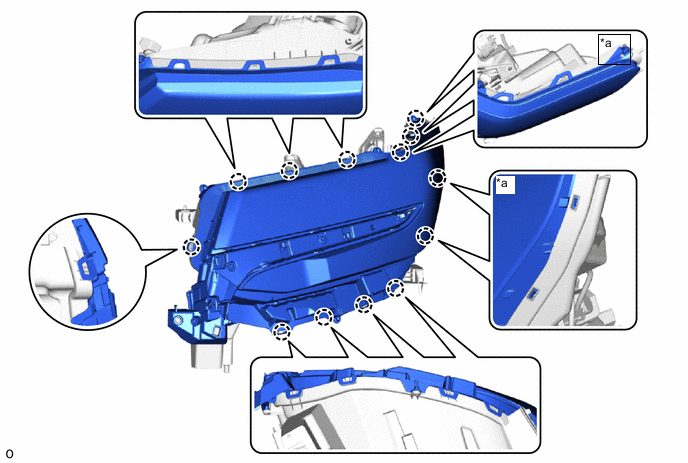

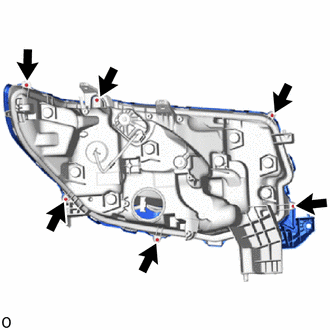

INSTALL HEADLIGHT LENS LH

Note

-

Perform work using clean rubber gloves.

-

Do not touch the inner surface of the lens and metallic surfaces as much as possible, or they may become dirty.

-

Do not allow metallic surfaces to become dirty, as such surfaces become damaged even if they are only lightly wiped with a soft cloth.

-

Do not use solvent to clean components. Only clean them with a dry cloth.

-

Area to Clean Clean the headlight lens gasket contact surface.

-

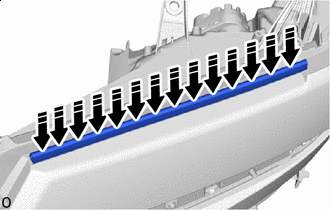

Set the headlight lens LH in place.

Note

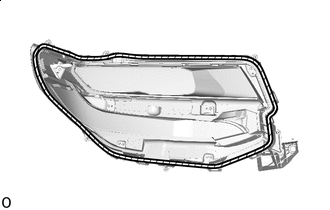

Headlight Lens Gasket

Headlight Housing

Headlight Lens LH Set the headlight lens LH in the middle of the headlight lens gasket as shown in the illustration.

-

Check that the entire circumference of the headlight lens LH is positioned above the middle of the headlight lens gasket.

-

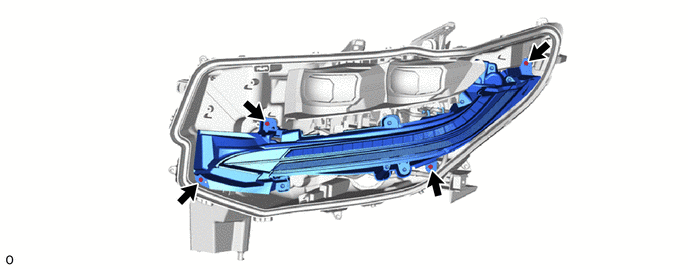

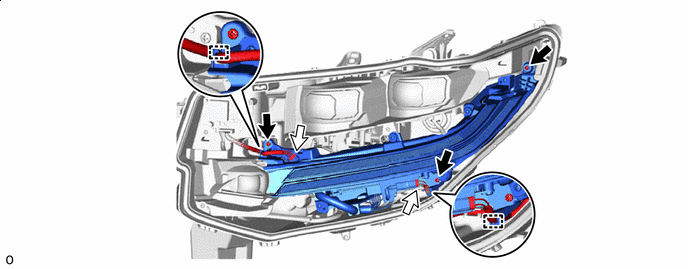

Install headlight lens LH:

Tech Tips

Install the headlight lens LH to the headlight housing from the starting point of installation toward the inside of the vehicle as shown in the illustration.

*a Installation Starting Point - -

Install in this Direction - - -

Attach the base point claw.

-

Attach the remaining claw to install the headlight lens LH.

*a Base Point Claw - - -

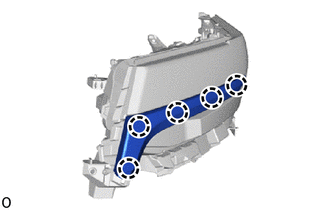

Install the 6 screws.

-

Check the condition of the headlight lens gasket.

OK Gasket contacts headlight lens LH and does not protrude out.

-

-

INSTALL HEADLIGHT GASKET

-

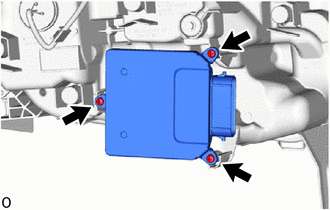

INSTALL HEADLIGHT ECU SUB-ASSEMBLY LH

Note

-

Prevention of static electricity is required during this procedure.

-

Use static electricity countermeasures SST (desktop antistatic mat set) and observe all precautions to prevent damage to the system by electrostatic discharge (ESD).

-

If the headlight ECU sub-assembly LH has been dropped, replace it with a new one.

-

If the headlight ECU sub-assembly LH has been removed, replace the headlight gasket with a new one.

-

Perform work using clean rubber gloves.

-

Do not touch the headlight ECU sub-assembly LH connector with bare hands.

- SST

- 09890-47010 ( 09891-04010, 09891-04020, 09891-04030, 09891-04040 )

-

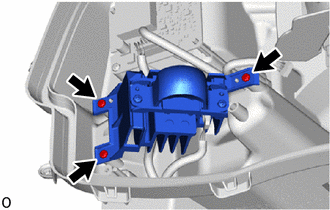

Connect each connector.

-

Install the headlight ECU sub-assembly LH with the 3 screws.

-

-

INSTALL HEADLIGHT PROTECTOR LH

-

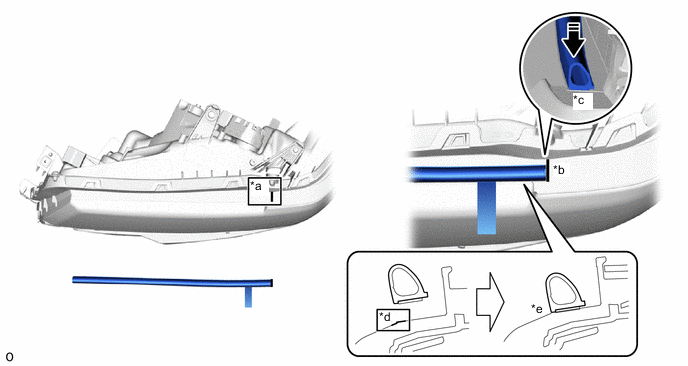

Area to Clean Clean the application area of the headlight protector LH shown in the illustration.

Note

Remove any remaining double-sided tape, and then clean and degrease the area.

-

Remove approximately 3 cm of the peeling paper from a new headlight protector LH.

-

Align the angle of the headlight protector LH with the application start position, and then set only the part with peeling paper removed into place.

Tech Tips

The application start position is not level.

-

Press the set portion of the part with your finger to secure it.

Note

Do not slide your finger horizontally, as doing so may stretch the part unnecessarily.

*a Application Start Position *b Align angle with application start position, and then set into place *c The application start position is not level *d Protrusion on the front of headlight lens LH *e Set the headlight protector LH flush with the protrusion on the front of headlight lens LH - -

Press Here - - -

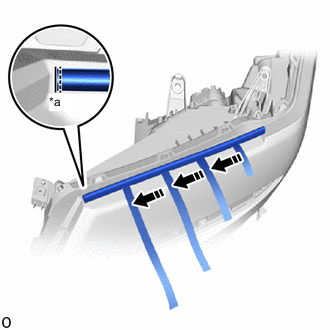

*a Alignment Line

Install in this Direction While peeling the peeling tape, position the headlight protector LH so that it is flush with the step on the front the headlight lens LH and set it to the application end position.

Tech Tips

Set the end point of the headlight protector LH so that it is between the two alignment lines.

-

Press Here Press the set portion of the part with your finger to secure it.

Note

Do not slide your finger horizontally, as doing so may stretch the part unnecessarily.

-

-

INSTALL HEADLIGHT COVER LH

-

Attach the claw to install the headlight cover LH.

-