PROPELLER SHAFT ASSEMBLY INSTALLATION

PROCEDURE

-

TEMPORARILY INSTALL PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

-

Completely remove any oil or the like and clean the contact surfaces of the rear transfer output shaft sub-assembly and propeller with center bearing shaft assembly.

-

Completely remove any oil or the like and clean the contact surfaces of the transmission coupling assembly and propeller with center bearing shaft assembly.

-

Align the matchmarks of the transfer assembly and propeller with center bearing shaft assembly.

-

Temporarily install the propeller with center bearing shaft assembly with the 4 nuts and 4 washers.

-

Align the matchmarks of the differential carrier assembly and propeller with center bearing shaft assembly.

-

Temporarily install the propeller with center bearing shaft assembly with the 4 nuts and 4 washers.

-

Temporarily install the center support bearing and 2 center No. 2 support bearing washers with the 2 bolts.

-

-

TIGHTEN PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

-

Tighten the 4 nuts of the propeller with center bearing shaft assembly and transfer assembly to the torque specification.

- Torque:

- 35 N*m { 357 kgf*cm, 26 ft.*lbf }

-

Tighten the 4 nuts of the propeller with center bearing shaft assembly and differential carrier assembly to the torque specification.

- Torque:

- 35 N*m { 357 kgf*cm, 26 ft.*lbf }

-

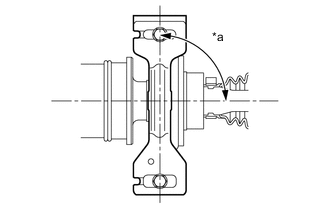

*a 90° Check that the center line of the center support bearing housing is perpendicular to the axis of the propeller shaft.

-

Tighten the 2 bolts of the center support bearing to the torque specification.

- Torque:

- 36.8 N*m { 375 kgf*cm, 27 ft.*lbf }

-

-

INSPECT AND ADJUST JOINT ANGLE

Note

Perform the measurement with a 4 post lift or pit so that the vehicle is supported by all 4 wheels as if it were on the ground.

-

Before the angle measurement, stabilize each part by performing procedures like those described below.

-

Rotate the propeller shaft several times by hand.

-

Set the jack to the differential, and raise and lower the differential.

-

-

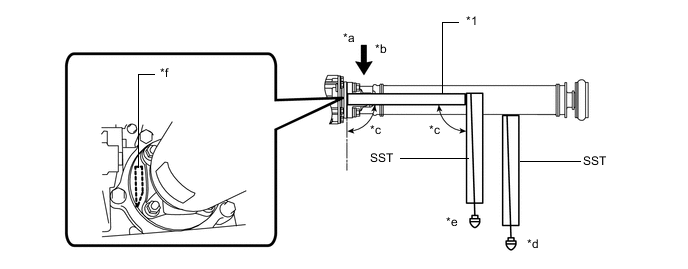

Using SST and a straightedge, measure the angle of the transfer flange (angle D) and the angle of the intermediate shaft (angle A).

- SST

- 09370-50010

Note

Make sure the straightedge and SST are at a right angle.

*1 Straightedge - - *a No. 1 Joint Angle *b D - A *c 90° *d Angle A *e Angle D *f Angle D Measurement Position

-

Subtract the measured angle of the intermediate shaft (angle A) from the measured angle of the transfer flange (angle D) to obtain the No. 1 joint angle.

No. 1 Joint Angle Measurement Position Engine Transmission No. 1 Joint Angle D - A 8AR-FTS Automatic Transaxle 2°22' +/- 60' 3ZR-FAE CVT 2°23' +/- 60'

-

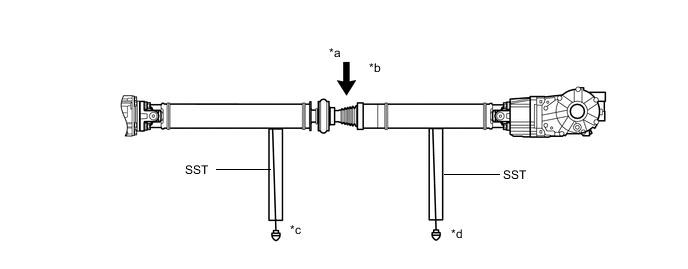

Using SST, measure the angle of the intermediate shaft (angle A) and the angle of the propeller shaft (angle B).

- SST

- 09370-50010

*a No. 2 Joint Angle *b A - B *c Angle A *d Angle B

-

Subtract the measured angle of the propeller shaft (angle B) from the measured angle of the intermediate shaft (angle A) to obtain the No. 2 joint angle.

No. 2 Joint Angle Measurement Position Engine Transmission No. 2 Joint Angle A - B 8AR-FTS Automatic Transaxle 1°49' +/- 1°30' 3ZR-FAE CVT 1°25' +/- 1°30'

-

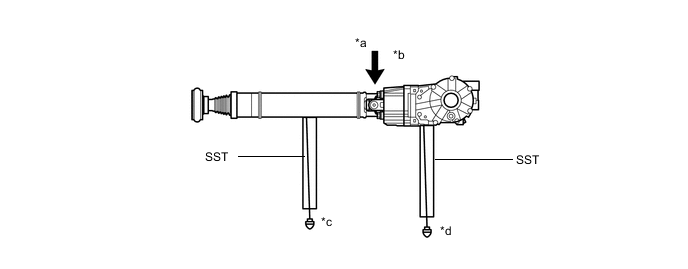

Using SST, measure the angle of the propeller shaft (angle B) and the angle of the rear differential (angle C).

- SST

- 09370-50010

*a No. 3 Joint Angle *b B - C *c Angle B *d Angle C

-

Subtract the measured angle of the propeller shaft (angle B) from the measured angle of the rear differential (angle C) to obtain the No. 3 joint angle.

No. 3 Joint Angle Measurement Position Engine Transmission No. 3 Joint Angle B - C 8AR-FTS Automatic Transaxle 2°09' +/- 60' 3ZR-FAE CVT 2°12' +/- 60'

-

If the measured angle of the propeller shaft is not within the specified range, or there is vibration or noise, use the following procedure to adjust the propeller shaft.

-

Support the propeller shaft with a jack.

-

Remove the 2 center bearing mounting bolts.

-

Slowly lower the jack and disconnect the center bearing.

-

Select an appropriate adjusting washer thickness from the table below, and obtain a washer set.

Standard Adjusting Washer Thickness 2.0 mm (0.0787 in.) 4.5 mm (0.1772 in.) 6.5 mm (0.2559 in.) Tech Tips

-

Use washers of the same thickness on the left and right sides.

-

Do not use 2 or more washers stacked together.

-

Install the washers.

-

-

-