CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM, Diagnostic DTC:P2767

| DTC Code | DTC Name |

|---|---|

| P2767 | Input / Turbine Speed Sensor "B" Circuit No Signal |

DESCRIPTION

The ECM detects the input shaft speed based on the signal from the transmission revolution sensor (NIN) and performs gear ratio control.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | MIL | Memory |

|---|---|---|---|---|---|

| P2767 | Input / Turbine Speed Sensor "B" Circuit No Signal | 1. Diagnosis Condition 2. Malfunction Status 3. Malfunction Time 4. Other

|

|

Comes on | DTC stored |

MONITOR DESCRIPTION

The ECM receives a signal from the transmission revolution sensor (NIN) installed in the continuously variable transaxle and determines the input shaft speed in order to control the gear ratio. If the ECM detects no signal from the transmission revolution sensor (NIN) even while the vehicle is moving, it will determine that there is a malfunction in the transmission revolution sensor (NIN). The ECM will illuminate the MIL and store this DTC.

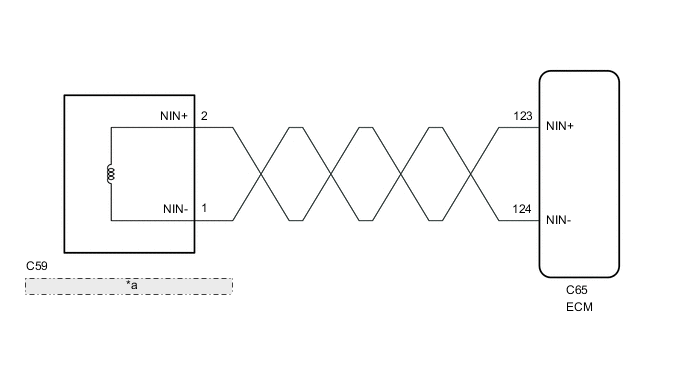

WIRING DIAGRAM

| *a | Transmission Revolution Sensor (NIN) |

CAUTION / NOTICE / HINT

Note

-

Perform initialization when parts related to the continuously variable transaxle are replaced.

-

Check that no DTCs are stored after performing initialization.

PROCEDURE

-

READ VALUE USING GTS (SPD (NIN), ENGINE SPEED AND LOCK UP)

-

Connect the GTS to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / Primary.

-

In accordance with the display on the GTS, read the Data List.

Powertrain > Engine and ECT > Data ListTester Display Measurement Item Range Normal Condition Diagnostic Note Engine Speed Engine speed Min.: 0 rpm

Max.: 16383 rpm

710 to 810 rpm: Idling When the crankshaft position sensor is malfunctioning, "Engine Speed" is approximately 0 rpm or varies greatly from the actual engine speed. SPD (NIN) Primary pulley speed (NIN) Min.: 0 rpm

Max.: 12750 rpm

-

0 rpm: Vehicle stopped

-

Primary pulley speed (NIN) equal to engine speed (NE): Lock-up ON (After warming up engine)

Data is displayed in increments of 50 rpm. Lock Up Lock-up OFF or ON

-

ON: Lock-up operating

-

OFF: Lock-up not operating

-

Powertrain > Engine and ECT > Data ListTester Display Engine Speed SPD (NIN) Lock Up Result Result Proceed to Data display is not within Normal Condition range A Data display is within Normal Condition range B -

B

REPLACE ECM Click here

A

-

-

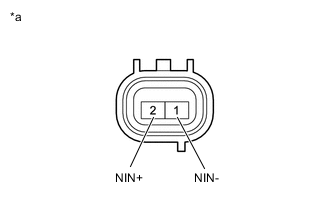

INSPECT TRANSMISSION REVOLUTION SENSOR (NIN)

-

*a Component without harness connected

(Transmission Revolution Sensor (NIN))

Disconnect the transmission revolution sensor (NIN) connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition 1 (NIN-) - 2 (NIN+) 20°C (68°F) 560 to 680 Ω Result Proceed to OK NG

NG

REPLACE TRANSMISSION REVOLUTION SENSOR (NIN) Click here

OK

-

-

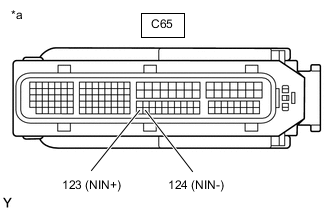

CHECK HARNESS AND CONNECTOR (TRANSMISSION REVOLUTION SENSOR (NIN) - ECM)

-

*a Front view of wire harness connector

(to ECM)

Disconnect the ECM connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition C65-123 (NIN+) - C65-124 (NIN-) 20°C (68°F) 560 to 680 Ω C65-123 (NIN+) - Body ground and other terminals Always 10 kΩ or higher C65-124 (NIN-) - Body ground and other terminals Always 10 kΩ or higher Result Proceed to OK NG

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR (TRANSMISSION REVOLUTION SENSOR (NIN) - ECM)

OK

-

-

REPLACE ECM

-

Replace the ECM.

Result Proceed to NEXT

NEXT

PERFORM INITIALIZATION Click here

-

-

REPLACE ECM

-

Replace the ECM.

Result Proceed to NEXT

NEXT

PERFORM INITIALIZATION Click here

-