ELECTRONICALLY CONTROLLED BRAKE SYSTEM, Diagnostic DTC:C1300

| DTC Code | DTC Name |

|---|---|

| C1300 | Skid Control ECU Malfunction |

DESCRIPTION

The skid control ECU (brake booster with master cylinder assembly) stores this DTC if malfunctions are found in the circuit inside the ECU by self diagnosis.

| DTC No. | Detection Item | INF Code | DTC Detection Condition | Trouble Area | Note |

|---|---|---|---|---|---|

| C1300 | Skid Control ECU Malfunction | 1028 to 1049 |

|

|

Electronically controlled brake system DTC |

CAUTION / NOTICE / HINT

Note

After replacing the skid control ECU (brake booster with master cylinder assembly), perform linear solenoid valve offset learning, ABS holding solenoid valve learning, yaw rate and acceleration sensor zero point calibration and system information memorization after performing "Reset Memory".

PROCEDURE

-

CLEAR DTC

-

Clear the DTCs.

Chassis > ABS/VSC/TRC > Clear DTCsResult Proceed to NEXT

NEXT

-

-

CHECK DTC

-

Turn the power switch off.

-

Turn the power switch on (IG).

-

Check if the same DTC is output.

Chassis > ABS/VSC/TRC > Trouble CodesResult Result Proceed to Only C1300 is output A Other than above B

B

REPAIR CIRCUITS INDICATED BY OUTPUT DTCS Click here

A

-

-

CHECK FREEZE FRAME DATA

-

Check the INF code from the Freeze Frame Data stored when DTC (C1300) was stored.

Chassis > ABS/VSC/TRC > DTC(C1300) > Freeze Frame DataTester Display Detailed Freeze DTC Result Result Proceed to INF codes 1028 to 1044 or 1047 to 1049 are output. A INF code 1046 is output. B INF code 1045 is output. C

A

REPLACE BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY for LHD: Click here

REPLACE BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY for RHD: Click hereC

INSPECT BRAKE BOOSTER PUMP ASSEMBLY Click here

B

-

-

CHECK FREEZE FRAME DATA

-

Using the GTS, read the "IG1 Voltage Value", "IG2 Voltage Value", "BS1 Voltage Value", "BS2 Voltage Value", "VM1 Voltage Value" and "VM2 Voltage Value" of the Freeze Frame Data stored when the DTC C1300 (INF code 1046) was stored.

Chassis > ABS/VSC/TRC > DTC(C1300) > Freeze Frame DataTester Display Detailed Freeze DTC IG1 Voltage Value IG2 Voltage Value BS1 Voltage Value BS2 Voltage Value VM1 Voltage Value VM2 Voltage Value Result Result Proceed to The value of any IG1 Voltage Value, IG2 Voltage Value, BS1 Voltage Value, BS2 Voltage Value, VM1 Voltage Value, VM2 Voltage Value is 7.00 V or less A The value of all IG1 Voltage Value, IG2 Voltage Value, BS1 Voltage Value, BS2 Voltage Value, VM1 Voltage Value, VM2 Voltage Value is 12.00 V or more B Tech Tips

If any of the voltage values of the Freeze Frame Data are 7.00 V or less, a sudden drop of the power source voltage is suspected as a cause of the DTC output.

In this case, inspect the auxiliary battery and replace or recharge the auxiliary battery as necessary.

B

CHECK AUXILIARY BATTERY Click here

A

-

-

CHECK AUXILIARY BATTERY

-

Check the auxiliary battery voltage.

Standard Voltage Tester Connection Condition Specified Condition Auxiliary battery Power switch on (IG) 11 to 14 V Auxiliary battery Power switch on (READY) 11 to 15.5 V Result Proceed to OK NG

OK

END

NG

CHARGE OR REPLACE AUXILIARY BATTERY

-

-

CHECK AUXILIARY BATTERY

-

Check the auxiliary battery voltage.

Standard Voltage Tester Connection Condition Specified Condition Auxiliary battery Power switch on (IG) 11 to 14 V Auxiliary battery Power switch on (READY) 11 to 15.5 V Result Proceed to OK NG

OK

REPLACE BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY for LHD: Click here

REPLACE BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY for RHD: Click hereNG

CHARGE OR REPLACE AUXILIARY BATTERY

-

-

INSPECT BRAKE BOOSTER PUMP ASSEMBLY

-

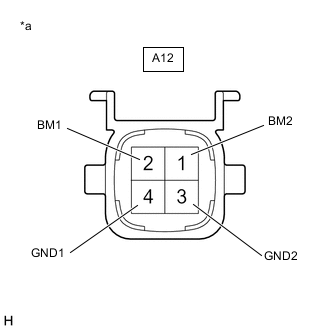

*a Component without harness connected

(Brake Booster Pump Assembly)

Turn the power switch off.

-

Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK The connector is securely connected. -

Disconnect the A12 brake booster pump assembly connector.

-

Check both the connector case and the terminals for deformation and corrosion.

OK No deformation or corrosion. -

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A12-2 (BM1) - A12-4 (GND1) Always 10 Ω or less A12-1 (BM2) - A12-3 (GND2) Always 10 Ω or less A12-2 (BM1) - A12-1 (BM2) Always Below 1 Ω A12-4 (GND1) - A12-3 (GND2) Always Below 1 Ω Result Proceed to OK NG

NG

REPLACE BRAKE BOOSTER PUMP ASSEMBLY for LHD: Click here

REPLACE BRAKE BOOSTER PUMP ASSEMBLY for RHD: Click hereOK

-

-

CHECK HARNESS AND CONNECTOR (GND TERMINAL)

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A12-4 (GND1) - Body ground Always Below 1 Ω A12-3 (GND2) - Body ground Always Below 1 Ω Result Proceed to OK NG

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR (GND CIRCUIT)

OK

-

-

CHECK HARNESS AND CONNECTOR (BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY - BRAKE BOOSTER PUMP ASSEMBLY)

-

Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK The connector is securely connected. -

Disconnect the A41 skid control ECU (brake booster with master cylinder assembly) connector.

-

Check both the connector case and the terminals for deformation and corrosion.

OK No deformation or corrosion. -

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A41-1 (MRO1) - A12-2 (BM1) Always Below 1 Ω A41-1 (MRO1) or A12-2 (BM1) - Body ground Always 10 kΩ or higher A41-27 (MRO2) - A12-1 (BM2) Always Below 1 Ω A41-27 (MRO2) or A12-1 (BM2) - Body ground Always 10 kΩ or higher Result Proceed to OK NG

OK

REPLACE BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY for LHD: Click here

REPLACE BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY for RHD: Click hereNG

REPAIR OR REPLACE HARNESS OR CONNECTOR

-