TURBOCHARGER INSPECTION

PROCEDURE

-

INSPECT TURBINE HOUSING WITH VALVE SUB-ASSEMBLY

-

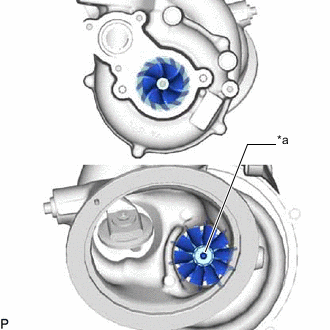

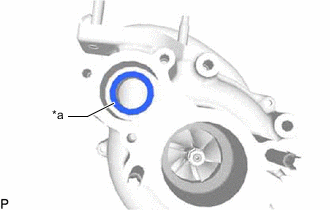

*a Center of Exhaust Side Turbine Check if the compressor side impeller and exhaust side turbine are damaged or defective.

Tech Tips

Wear on the center of the exhaust side turbine is not a malfunction.

-

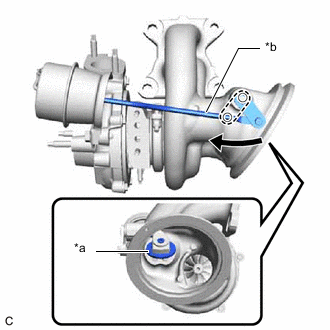

*a Waste Gate Valve *b Rod Move the rod by hand and check whether the waste gate valve is stuck.

-

Using a straightedge and feeler gauge, check the turbine housing with valve sub-assembly installation surface for warpage.

Standard Warpage 0.20 mm (0.00787 in.) If the result is not as specified, replace the turbine housing with valve sub-assembly.

-

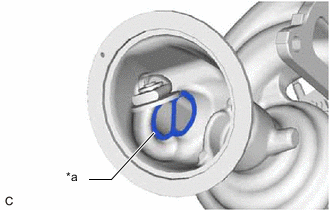

*a Contact Surface of Waste Gate Valve Port Close the waste gate valve and using a feeler gauge, measure the clearance between the waste gate valve and the contact surface of the valve port of the turbine housing with valve sub-assembly waste gate.

Standard Clearance 0.50 mm (0.0197 in.) If the result is not as specified, replace the turbine housing with valve sub-assembly.

-

-

INSPECT COMPRESSOR HOUSING WITH BEARING SUB-ASSEMBLY

-

Oil Leakage Check Area Check the areas shown in the illustration for oil leaks.

OK There are no oil leaks from the compressor housing with bearing sub-assembly. Note

Oil on the inlet side of the compressor is from oil in the blow-by gas and is not a malfunction.

If the result is not as specified, replace the compressor housing with bearing sub-assembly.

-

*a Contact Surface of Intake Air Control Valve (Air By-pass Valve Assembly) Check the area of the contact surface of the intake air control valve (air by-pass valve assembly) shown in the illustration for wear and deposits.

OK Contact surface wear of intake air control valve (air by-pass valve assembly) is 0.50 mm (0.0197 in.) or less. Tech Tips

If there are any deposits on the contact surface of the intake air control valve (air by-pass valve assembly), remove them.

If the result is not as specified, replace the compressor housing with bearing sub-assembly.

-

-

INSPECT TURBINE SHAFT

-

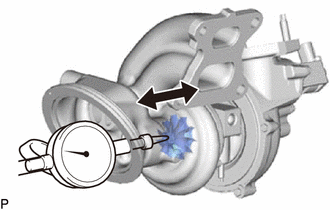

Check that the turbine shaft rotates smoothly.

-

Check the turbine shaft in the axial direction.

-

Set a dial indicator to the outlet side of the turbine shaft.

-

Move the turbine shaft in the axial direction and check for play.

Standard Axial Play 0.10 mm (0.00394 in.) or less If the result is not as specified, replace the compressor housing with bearing sub-assembly.

-