ВЫПУСКНОЙ КОЛЛЕКТОР С ТУРБОНАГНЕТАТЕЛЕМ УСТАНОВКА

PROCEDURE

-

INSTALL EXHAUST MANIFOLD

-

Install 2 new gaskets to the cylinder head sub-assembly.

-

Temporarily install the exhaust manifold with the 8 nuts.

-

Tighten the 8 nuts of the exhaust manifold.

- Torque:

- 11 N*m { 112 kgf*cm, 8 ft.*lbf }

-

Tighten the 8 nuts again.

- Torque:

- 13 N*m { 133 kgf*cm, 10 ft.*lbf }

-

-

INSTALL EGR COOLER ASSEMBLY WITH EGR VALVE ASSEMBLY

-

INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

-

CONNECT FUEL FEED PIPE SUB-ASSEMBLY

-

CONNECT NO. 1 AIR TUBE ASSEMBLY

-

Connect the No. 1 air tube assembly to the manual transaxle assembly with the 2 bolts.

- Torque:

- 24 N*m { 245 kgf*cm, 18 ft.*lbf }

-

Connect the outlet heater water hose to the No. 2 radiator pipe, and slide the clamp to secure the hose.

-

Connect the water hose sub-assembly to the No. 1 radiator pipe, and slide the clamp to secure the hose.

-

Attach the clamp and connect the water hose sub-assembly to the compressor outlet elbow.

-

Connect the water by-pass hose assembly to the No. 2 radiator pipe, and slide the clamp to secure the hose.

-

Connect the radiator hose sub-assembly to the No. 1 radiator pipe, and slide the clamp to secure the hose.

-

-

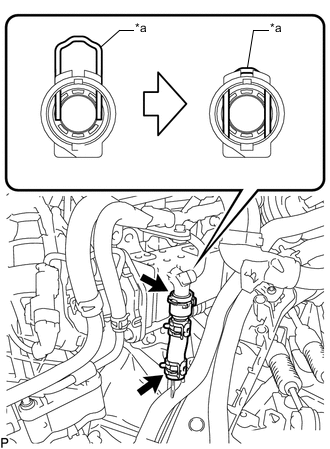

INSTALL NO. 4 WATER BY-PASS HOSE

-

Install the No. 4 water by-pass hose to the No. 2 radiator pipe, and slide the clamp to secure the hose.

-

*a Retainer Connect the No. 4 water by-pass hose to the EGR cooler assembly and lock the retainer as shown in the illustration.

-

-

CONNECT ENGINE WIRE

-

Connect the engine wire to the No. 1 air tube assembly with the 2 bolts.

- Torque:

- 8.4 N*m { 86 kgf*cm, 74 in.*lbf }

-

Attach the 2 clamps to the No. 1 air tube assembly.

-

-

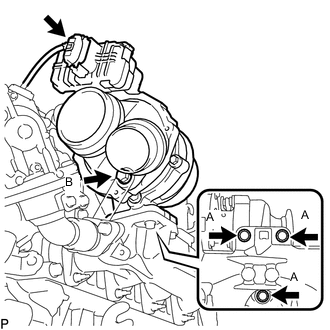

INSTALL TURBOCHARGER SUB-ASSEMBLY

-

Temporarily install a new gasket, the turbocharger sub-assembly and the 3 bolts (A).

-

Temporarily install the bolt (B).

-

Tighten the 4 bolts.

- Torque:

- for bolt (A)

- 25 N*m { 255 kgf*cm, 18 ft.*lbf }

- for bolt (B)

- 10 N*m { 102 kgf*cm, 7 ft.*lbf }

-

Connect the connector to the turbocharger sub-assembly.

-

-

INSTALL NO. 1 EXHAUST MANIFOLD PIPE

-

Temporarily install the No. 1 exhaust manifold pipe with the bolt.

-

Temporarily install 2 new gaskets with the union bolt.

-

Tighten the bolt and union bolt.

- Torque:

- for bolt

- 8.0 N*m { 82 kgf*cm, 71 in.*lbf }

- for union bolt

- 35 N*m { 357 kgf*cm, 26 ft.*lbf }

-

Connect the exhaust manifold pressure sensor connector.

-

-

CONNECT NO. 1 TURBO OIL PIPE

-

Connect the No. 1 turbo oil pipe and 2 new gaskets with the union bolt.

- Torque:

- 22 N*m { 224 kgf*cm, 16 ft.*lbf }

-

-

INSTALL TURBO OIL OUTLET PIPE

-

Install a new O-ring to the turbo oil outlet pipe.

-

Install a new gasket and the turbo oil outlet pipe with the 3 bolts.

- Torque:

- 10 N*m { 102 kgf*cm, 7 ft.*lbf }

-

-

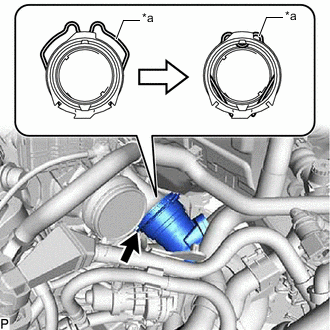

CONNECT COMPRESSOR OUTLET ELBOW

-

*a Retainer Connect the compressor outlet elbow to the turbocharger sub-assembly and lock the retainer as shown in the illustration.

-

-

INSTALL AIR CLEANER CASE SUB-ASSEMBLY

-

Install the air cleaner case sub-assembly with the 3 bolts.

- Torque:

- 7.0 N*m { 71 kgf*cm, 62 in.*lbf }

-

-

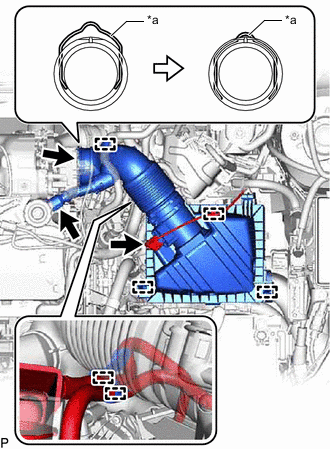

INSTALL AIR CLEANER CAP SUB-ASSEMBLY WITH AIR CLEANER HOSE ASSEMBLY

-

Install the air cleaner filter element sub-assembly to the air cleaner case sub-assembly.

-

*a Retainer Connect the air cleaner hose assembly to the turbocharger sub-assembly and lock the retainer as shown in the illustration.

-

Attach the 2 clamps to install the air cleaner cap sub-assembly.

-

Connect the ventilation hose to the cylinder head cover sub-assembly.

-

Attach the clamp and connect the No. 2 fuel hose to the air cleaner hose assembly.

-

Attach the clamp and connect the No. 1 fuel hose to the air cleaner hose assembly.

-

Attach the clamp and connect the vacuum hose to the air cleaner hose assembly.

-

Attach the clamp and connect the mass air flow meter sub-assembly connector.

-

-

INSTALL BATTERY BRACKET REINFORCEMENT

-

Install the battery bracket reinforcement with the 2 bolts.

- Torque:

- 20 N*m { 204 kgf*cm, 15 ft.*lbf }

-

-

INSTALL BATTERY CARRIER ASSEMBLY

-

Install the battery carrier assembly with the 3 bolts.

- Torque:

- 20 N*m { 204 kgf*cm, 15 ft.*lbf }

-

Install the ground wire to the battery carrier assembly with the bolt.

- Torque:

- 19.2 N*m { 196 kgf*cm, 14 ft.*lbf }

-

Attach the clamp to connect the engine wire.

-

-

INSTALL BATTERY TRAY

-

INSTALL BATTERY

-

INSTALL BATTERY INSULATOR

-

INSTALL BATTERY CLAMP SUB-ASSEMBLY

-

Attach the hook of the battery clamp sub-assembly to the battery carrier assembly.

-

Partially tighten the nut and temporarily install the bolt.

-

Adjust the battery clamp sub-assembly position.

-

Tighten the nut and bolt.

- Torque:

- for bolt

- 16.5 N*m { 168 kgf*cm, 12 ft.*lbf }

- for nut

- 4.9 N*m { 50 kgf*cm, 43 in.*lbf }

-

-

INSTALL EXHAUST MANIFOLD CONVERTER SUB-ASSEMBLY

-

CONNECT CABLE TO POSITIVE BATTERY TERMINAL

-

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

Note

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

-

ADD ENGINE COOLANT

-

INSPECT FOR COOLANT LEAK