MANUAL TRANSAXLE ASSEMBLY INSTALLATION

PROCEDURE

-

INSTALL MANUAL TRANSAXLE ASSEMBLY

-

Align the input shaft assembly with the clutch disc assembly and install the manual transaxle assembly to the engine.

Note

Make sure that the dowel pins are not loose, bent, damaged or scratched and then install the manual transaxle assembly to the engine with the contact surfaces of the engine and transaxle flat against each other.

-

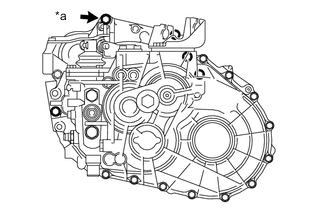

*a Temporarily Temporarily install the manual transaxle assembly with the bolt (*a).

-

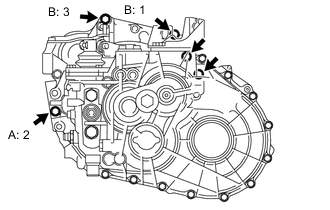

Tighten the 3 bolts labeled A and B in the order shown in the illustration, and then install the 2 bolts.

- Torque:

- for bolt A

- 46 N*m { 469 kgf*cm, 34 ft.*lbf }

- for bolt B

- 64 N*m { 653 kgf*cm, 47 ft.*lbf }

-

-

INSTALL STIFFENER PLATE LH

-

INSTALL STIFFENER PLATE RH

-

INSTALL OIL PAN INSULATOR

-

INSTALL ENGINE MOUNTING BRACKET LH

Tech Tips

Perform this procedure only when replacement of the engine mounting bracket LH is necessary.

-

Install the engine mounting bracket LH with the 4 bolts.

- Torque:

- 64 N*m { 653 kgf*cm, 47 ft.*lbf }

-

-

INSTALL REAR ENGINE MOUNTING BRACKET

-

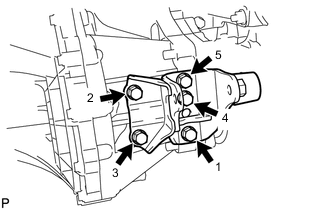

Temporarily install the rear engine mounting bracket with the 5 bolts.

-

Tighten the 5 bolts of the rear engine mounting bracket in the order shown in the illustration.

- Torque:

- 45 N*m { 459 kgf*cm, 33 ft.*lbf }

-

-

INSTALL FRONT ENGINE MOUNTING BRACKET

-

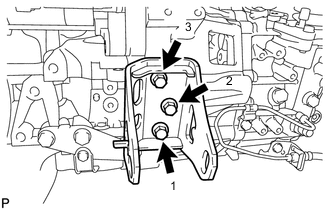

Temporarily install the front engine mounting bracket with the 3 bolts.

-

Tighten the 3 bolts of the front engine mounting bracket in the order shown in the illustration.

- Torque:

- 64 N*m { 653 kgf*cm, 47 ft.*lbf }

-

-

INSTALL ENGINE ASSEMBLY WITH MANUAL TRANSAXLE