OIL PUMP INSPECTION

PROCEDURE

-

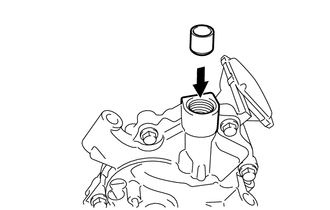

INSPECT OIL PUMP RELIEF VALVE

-

Coat the oil pump relief valve with engine oil and check that it falls smoothly into the valve hole by its own weight.

If it does not, replace the oil pump relief valve. If necessary, replace the oil pump assembly.

-

-

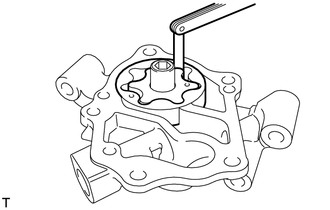

INSPECT OIL PUMP ROTOR

-

Check the tip clearance.

-

Using a feeler gauge, measure the clearance between the oil pump drive rotor and oil pump driven rotor tips.

Standard tip clearance 0.08 to 0.16 mm (0.00315 to 0.00630 in.) Maximum tip clearance 0.35 mm (0.0138 in.) If the tip clearance is more than the maximum, replace the oil pump assembly.

-

-

Check the side clearance.

-

Using a feeler gauge and precision straightedge, measure the clearance between the 2 rotors and precision straightedge.

Standard side clearance 0.03 to 0.08 mm (0.00118 to 0.00315 in.) Maximum side clearance 0.16 mm (0.00630 in.) If the side clearance is more than the maximum, replace the oil pump assembly.

-

-

Check the body clearance.

-

Using a feeler gauge, measure the clearance between the driven rotor and oil pump body.

Standard body clearance 0.12 to 0.19 mm (0.00472 to 0.00748 in.) Maximum body clearance 0.325 mm (0.0128 in.) If the body clearance is more than the maximum, replace the oil pump assembly.

-

-