ДВИГАТЕЛЬ ПРОВЕРКА БЕЗ СНЯТИЯ С АВТОМОБИЛЯ

PROCEDURE

-

INSPECT INJECTION TIMING

-

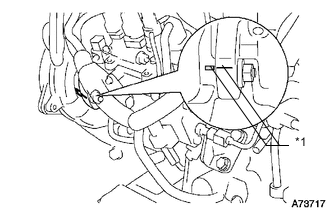

Text in Illustration *1 Matchmark Using a mirror, check that the matchmarks of the injection pump flange and timing belt case are aligned.

-

-

ADJUST INJECTION TIMING

-

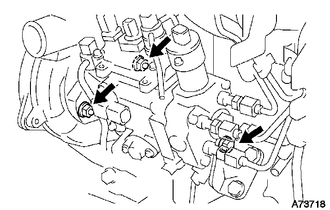

Loosen the following nuts and bolts.

-

The bolt holding the injection pump to the injection pump stay.

-

The 2 nuts holding the injection pump to the timing belt case.

-

-

Align the matchmark by slightly tilting the injection pump.

-

Tighten the following nuts and bolts.

-

The 2 nuts holding the injection pump to the timing belt case.

- Torque:

- 21 N*m { 209 kgf*cm, 15 ft.*lbf }

-

The bolt holding the injection pump to the injection pump stay.

- Torque:

- 26 N*m { 265 kgf*cm, 19 ft.*lbf }

-

-

-

INSPECT ENGINE IDLE SPEED

-

Warm up the engine.

-

When using the intelligent tester:

-

Connect the intelligent tester to the DLC3.

Idle speed 720 to 820 rpm Note

-

Turn all the electrical systems and the A/C off.

-

When checking the idling speed, the shift lever should be in neutral.

Tech Tips

Refer to the intelligent tester operator's manual for further details.

-

-

-

Text in Illustration *a Front View of DLC3 When not using an intelligent tester:

-

Using SST, connect the tachometer test probe to terminal 9 (TAC) of the DLC3.

- SST

- 09843-18040

-

Check the idle speed.

Standard idle speed 720 to 820 rpm Note

-

Turn all the electrical systems and the A/C off.

-

When checking the idling speed, the shift lever should be in neutral.

-

Confirm the terminal number before connecting them. Connecting the wrong terminal can be damage the engine.

-

-

-

-

INSPECT MAXIMUM ENGINE SPEED

-

Start the engine.

-

Fully depress the accelerator pedal.

-

Check the maximum speed.

Maximum engine speed 4850 to 4950 rpm

-

-

INSPECT COMPRESSION

Tech Tips

If there is a lack of power, excessive oil consumption or poor fuel economy is suspected. Measure the compression pressure.

-

Warm up and stop the engine.

-

Remove the glow plugs.

-

Disconnect the spill control valve connector.

-

Check the cylinder compression pressure.

-

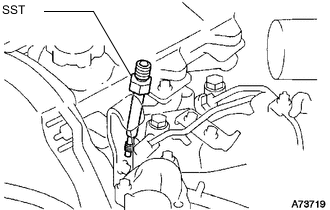

Install SST (attachment) to the glow plug hole.

- SST

- 09992-00026 ( 09992-00121 )

- Torque:

- 13 N*m { 133 kgf*cm, 10 ft.*lbf }

-

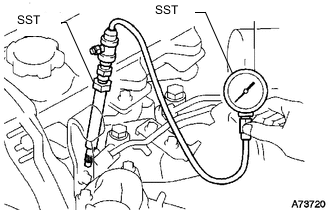

Connect SST (compression gauge) to SST (attachment).

- SST

- 09992-00026 ( 09992-00121, 09992-00211 )

-

Fully open the throttle valve, and start the engine.

-

While cranking the engine, measure the compression pressure.

Note

This measurement must be done as quickly as possible.

Tech Tips

Always use a fully charged battery to obtain an engine speed of 250 rpm or more.

-

-

Repeat the steps above for each cylinder.

Standard compression pressure 3138 kPa (32.0 kgf/cm2, 455 psi) or higher Minimum pressure 1961 kPa (20.0 kgf/cm2, 284 psi) Difference between each cylinder 490 kPa (5.0 kgf/cm2, 71 psi) or less If the cylinder compression in one or more cylinders is low, pour a small amount of engine oil into the cylinder through the glow plug hole and check the compression pressure for the cylinder with low compression.

Tech Tips

-

If adding oil helps the compression, the piston rings and/or cylinder bore may be worn or damaged.

-

If the pressure stays low, a valve may be stuck or the seating may be improper, or there may be leakage past the gasket.

-

-

Remove SST.

-

Reinstall the glow plugs.

-

Reconnect the spill control valve connector.

-