DIFFERENTIAL CASE INSPECTION

PROCEDURE

-

INSPECT FRONT DIFFERENTIAL CASE ASSEMBLY WITH RING GEAR

-

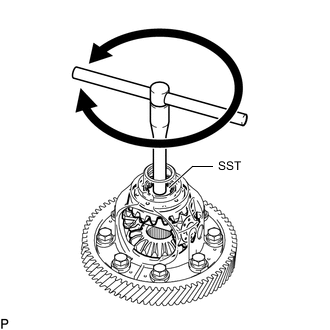

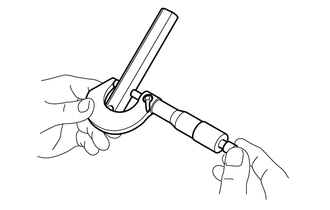

Using SST, rotate the front differential side gear as shown in the illustration.

- SST

- 09528-52010 ( 09528-05040 )

Standard The front differential side gear does not lock when rotated in either direction.

-

If the front differential side gear locks, perform all inspections.

-

If the front differential side gear still locks even after replacing the malfunctioning parts, replace the front differential case assembly with ring gear.

-

-

INSPECT FRONT DIFFERENTIAL SIDE GEAR THRUST AMOUNT

-

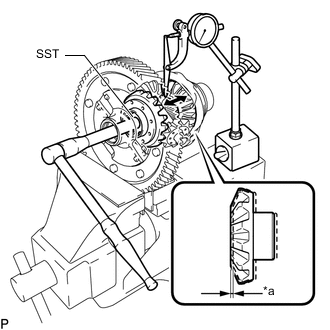

Secure the front differential case assembly with ring gear in a vise between aluminum plates.

Note

Do not overtighten the vise.

-

*a Front Differential Side Gear Thrust Amount Using SST and a dial indicator, measure the front differential side gear thrust amount.

- SST

- 09528-52010 ( 09528-05040 )

Front Differential Side Gear Thrust Amount 0.08 mm (0.00315 in.) or less Tech Tips

-

Measure the front differential side gear thrust amount while slowly rotating the front differential side gear.

-

Make sure to measure the front differential side gear thrust amount for both of the 2 front differential side gears.

If the result is not as specified, replace the 2 front differential side gears, 2 front differential pinions and 2 conical springs.

-

-

INSPECT FRONT DIFFERENTIAL PINION BACKLASH

-

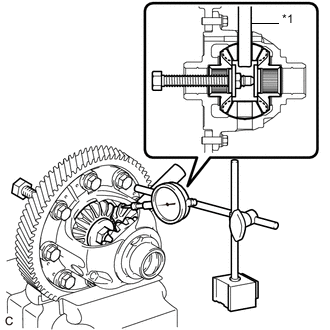

Install SST as shown in the illustration and tighten it.

*a Turn *b Hold - SST

- 09528-52010 ( 09953-05010, 09528-05020 )

- Torque:

- 10 N*m { 102 kgf*cm, 7 ft.*lbf }

-

Secure the front differential case assembly with ring gear in a vise between aluminum plates.

Note

Do not overtighten the vise.

-

*1 Front No. 1 Differential Pinion Shaft Install the front No. 1 differential pinion shaft to the front differential pinion as shown in the illustration.

-

Using a dial indicator, measure the front differential pinion backlash.

Standard Backlash 0.20 mm (0.00787 in.) or less If the backlash is not as specified, replace the front No. 1 differential side gear thrust washers with washers of a different thickness. Use the table below to select a front No. 1 differential side gear thrust washer which will ensure that the backlash is within the specification.

Front No. 1 Differential Side Gear Thrust Washer Thickness Mark Thickness mm (in.) 19 0.90 (0.0354) 14 0.95 (0.0374) 02 1.00 (0.0394) 15 1.05 (0.0413) 03 1.10 (0.0433) 16 1.15 (0.0453) 04 1.20 (0.0472) Tech Tips

Select front No. 1 differential side gear thrust washers of the same thickness for both the right and left side.

-

-

INSPECT FRONT DIFFERENTIAL PINION THRUST WASHER

-

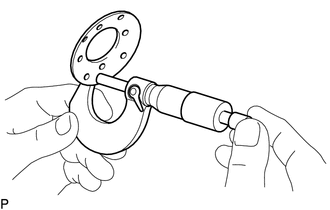

Using a micrometer, measure the thickness of the front differential pinion thrust washer.

Minimum Thickness 0.92 mm (0.0362 in.) Tech Tips

Measure the most worn portion of the front differential pinion thrust washer.

If the thickness is less than the minimum, replace the front differential pinion thrust washer.

-

-

INSPECT FRONT NO. 1 DIFFERENTIAL PINION SHAFT

-

Using a micrometer, measure the outer diameter of the front No. 1 differential pinion shaft.

Minimum Outer Diameter 16.982 mm (0.669 in.) Tech Tips

Measure the most worn portion of the front No. 1 differential pinion shaft.

If the outer diameter is less than the minimum, replace the front No. 1 differential pinion shaft.

-