CANISTER INSPECTION

PROCEDURE

-

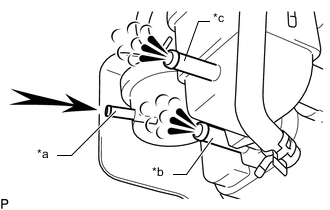

INSPECT CANISTER

-

Text in Illustration *a Port A *b Port B *c Port C

Air Visually check the canister for cracks or damage.

-

Blow compressed air of 4.9 kPa (0.05 kgf/cm2, 0.7 psi) into port A and check that air flows without resistance from port B and port C.

If the result is not as specified, replace the canister.

-

Apply a vacuum of 1.96 kPa (15 mmHg, 0.579 in.Hg) to port A. Check that the vacuum does not decrease when ports B and C are closed, and check that air flows when port B is opened.

If the result is not as specified, replace the canister.

-

-

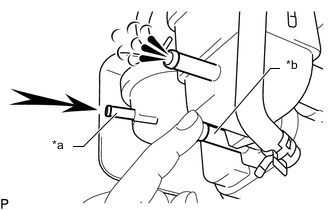

CLEAN FILTER IN CANISTER

-

Text in Illustration *a Port A *b Port B

Air Clean the filter by blowing compressed air of 4.9 kPa (0.05 kgf/cm2, 0.7 psi) into port A while holding port B closed.

Note

Do not attempt to wash the canister.

-