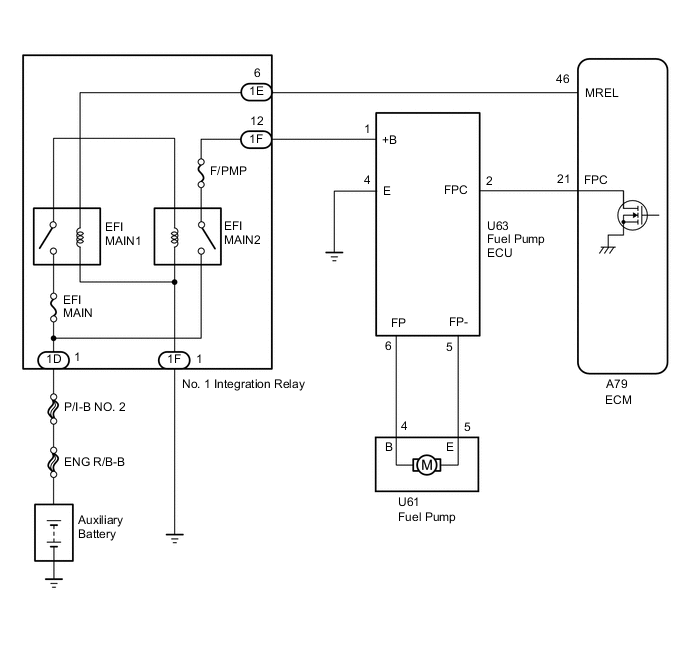

SFI SYSTEM(w/ EGR System) Fuel Pump Control Circuit

DESCRIPTION

The fuel pump circuit consists of the ECM, fuel pump and fuel pump ECU (which operates the fuel pump). Based on the engine output, the ECM determines the fuel pump speed. The speed is then converted to a duty signal and sent to the fuel pump ECU. Based on the signal sent from the ECM, the fuel pump ECU adjusts the fuel pump operation speed.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

Note

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

-

PERFORM ACTIVE TEST USING GTS (CONTROL THE FUEL PUMP/SPEED)

-

Connect the GTS to the DLC3.

-

Turn the power switch on (IG).

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Fuel Pump/Speed.

-

Check whether operating sounds can be heard while operating the fuel pump using the GTS.

OK Operating sounds can be heard from fuel pump.

NG

INSPECT FUEL PUMP ECU (POWER SOURCE VOLTAGE) Click here

OK

-

-

PERFORM ACTIVE TEST USING GTS (CONTROL THE FUEL PUMP)

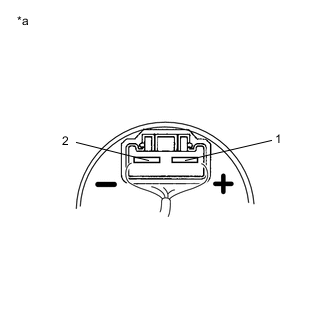

Text in Illustration *a Component with harness connected

(Fuel Pump)

-

Remove the fuel tank assembly Click here.

-

Remove the fuel pump from the fuel tank assembly.

-

Clean the fuel pump to completely remove any remaining fuel.

-

Connect the fuel pump connector.

CAUTION:

Make sure that there is no fuel remaining inside or on the outside of the fuel pump.

-

Connect the GTS to the DLC3.

-

Turn the power switch on (IG).

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Fuel Pump Duty.

-

Operate the fuel pump using the Active Test function and measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection GTS Operation Specified Condition 1 - 2 FPC Duty: 25% 3.2 to 4.05 V FPC Duty: 80% 8.8 to 12.5 V -

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Fuel Pump/Speed.

-

Operate the fuel pump using the Active Test function and measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection GTS Operation Specified Condition 1 - 2 ON (FPC Duty: 90%) 9.0 to 14.0 V Tech Tips

-

Be sure to measure the voltage with all the connectors connected.

-

Before performing this inspection, check that the auxiliary battery voltage is between 11 and 14 V (not depleted).

-

NG

INSPECT FUEL PUMP Click here

OK

-

-

INSPECT FUEL PUMP

-

Inspect the fuel pump Click here.

OK

END

NG

-

-

REPLACE FUEL PUMP

-

Replace the fuel pump Click here.

Tech Tips

Perform "Inspection After Repair" after replacing the fuel pump Click here.

NEXT

-

-

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

-

Check the fuel pump operation.

OK Malfunction has been repaired successfully.

OK

END

NG

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE Click here

-

-

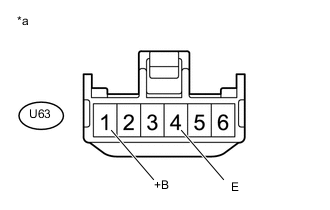

INSPECT FUEL PUMP ECU (POWER SOURCE VOLTAGE)

Text in Illustration *a Front view of wire harness connector

(to Fuel Pump ECU)

-

Disconnect the fuel pump ECU connector.

-

Turn the power switch on (IG).

-

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Switch Condition Specified Condition U63-1 (+B) - U63-4 (E) Power switch on (IG) 11 to 14 V

NG

CHECK HARNESS AND CONNECTOR (FUEL PUMP ECU - BODY GROUND) Click here

OK

-

-

INSPECT FUEL PUMP

-

Inspect the fuel pump.

NG

REPLACE FUEL PUMP Click here

OK

-

-

CHECK HARNESS AND CONNECTOR (FUEL PUMP - FUEL PUMP ECU)

-

Disconnect the fuel pump connector.

-

Disconnect the fuel pump ECU connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition U61-4 (B) - U63-6 (FP) Always Below 1 Ω U61-5 (E) - U63-5 (FP-) Always Below 1 Ω U61-4 (B) or U63-6 (FP) - Body ground Always 10 kΩ or higher U61-5 (E) or U63-5 (FP-) - Body ground Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK HARNESS AND CONNECTOR (FUEL PUMP ECU - ECM)

-

Disconnect the fuel pump ECU connector.

-

Disconnect the ECM connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition U63-2 (FPC) - A79-21 (FPC) Always Below 1 Ω U63-2 (FPC) or A79-21 (FPC) - Body ground Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

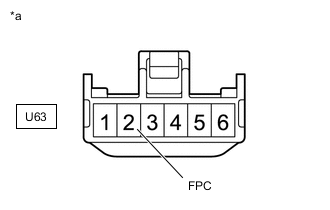

INSPECT ECM (FPC TERMINAL)

-

*a Front view of wire harness connector

(to Fuel Pump ECU)

Disconnect the fuel pump ECU connector.

-

Connect the GTS to the DLC3.

-

Turn the power switch on (IG).

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Fuel Pump / Speed.

-

Operate the fuel pump control ECU assembly using the Active Test function and measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection GTS Operation Specified Condition U63-2 (FPC) - Body ground Before Active Test → During Active Test Before Active Test: Resistance is stable → During Active Test: Resistance fluctuates* Tech Tips

*: Using the Active Test, duty control of the transistors in the ECM will be performed. Due to the duty control, resistance of the FPC terminal will be unstable during the Active Test. If the resistance is stable before the Active Test and fluctuates while performing the Active Test, it can be determined that the transistor is operating. If the transistor does not operate during the Active Test, the ECM may be malfunctioning.

OK

REPLACE FUEL PUMP ECU Click here

NG

REPLACE ECM Click here

-

-

CHECK HARNESS AND CONNECTOR (FUEL PUMP ECU - BODY GROUND)

-

Disconnect the fuel pump ECU connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition U63-4 (E) - Body ground Always Below 1 Ω

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK HARNESS AND CONNECTOR (EFI MAIN2 RELAY - FUEL PUMP ECU)

-

Remove the No. 1 integration relay from the No. 1 engine room relay block and junction block assembly.

-

Disconnect the fuel pump ECU connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition 1F-12 - U63-1 (+B) Always Below 1 Ω 1F-12 or U63-1 (+B) - Body ground Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

INSPECT NO. 1 INTEGRATION RELAY (EFI MAIN2)

-

Inspect the No. 1 integration relay (EFI MAIN2) Click here.

OK

GO TO ECM POWER SOURCE CIRCUIT Click here

NG

REPLACE NO. 1 INTEGRATION RELAY

-