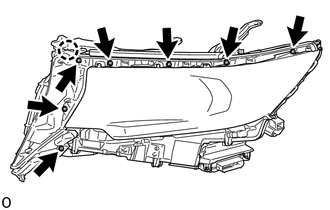

HEADLIGHT ASSEMBLY(for LED Headlight) DISASSEMBLY

PROCEDURE

-

PRECAUTION

Note

-

Be sure to read Precaution thoroughly before servicing.

-

Handle components indoors as much as possible to prevent foreign matter from entering and adhering to headlight assembly components.

-

Do not reuse parts which have reduced fastening ability due to thread damage.

-

Do not touch the inner surface of the lens and metallic surfaces as much as possible, or they may become dirty

-

Do not allow metallic surfaces to become dirty, as such surfaces become damaged even if they are only lightly wiped with a soft cloth.

-

When installing components, make sure that the wire harness is not pinched or pulled.

-

Do not use solvent to clean components. Only clean them with a dry cloth.

Tech Tips

-

Use the same procedure for the RH and LH sides.

-

The procedure listed below is for the LH side.

-

-

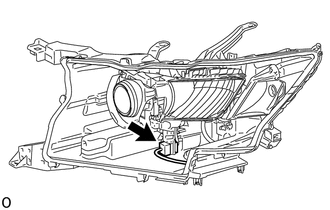

REMOVE FRONT TURN SIGNAL LIGHT BULB

-

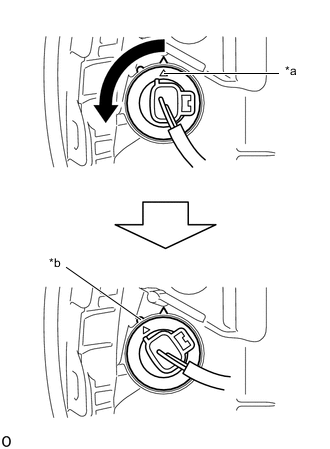

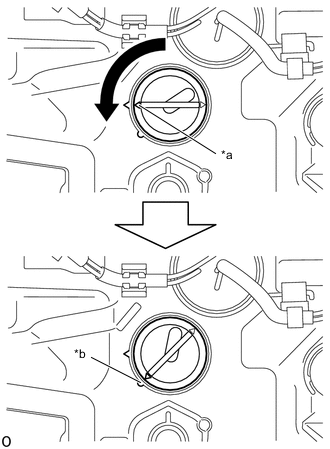

*a Matchmark *b Unlock Position Mark Turn the bulb socket counterclockwise until the matchmark is aligned with the unlock position mark to disconnect the bulb socket.

-

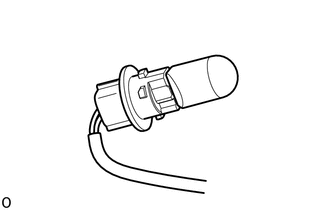

Remove the front turn signal light bulb from the bulb socket.

-

-

REMOVE NO. 1 HEADLIGHT ECU SUB-ASSEMBLY LH

-

REMOVE HEADLIGHT GASKET

-

REMOVE FRONT BUMPER BAR REINFORCEMENT LH

-

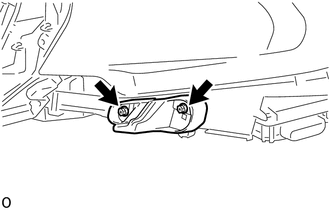

Remove the 2 screws and front bumper bar reinforcement LH.

-

-

REMOVE HEADLIGHT SEAL

-

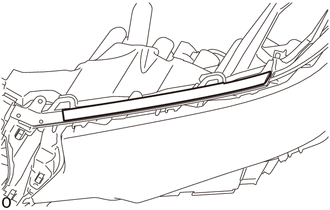

Remove the headlight seal.

Note

The headlight seal must not be reused.

-

-

REMOVE HEADLIGHT BRACKET LH

-

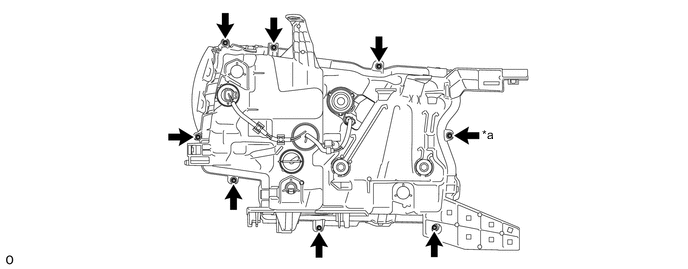

Remove the 7 screws.

-

Detach the claw and remove the headlight bracket LH.

-

-

REMOVE HEADLIGHT LENS LH

Note

-

Prevention of static electricity is required during this procedure.

-

Use static electricity countermeasures SST (desktop anti-static mat set) and observe all precautions to prevent damage to the system by electrostatic discharge (ESD).

-

Perform work using clean rubber gloves.

-

Do not touch the inner surface of the lens and metallic surfaces as much as possible, or they may become dirty.

-

Do not allow metallic surfaces to become dirty, as such surfaces become damaged even if they are only lightly wiped with a soft cloth.

-

Do not use solvent to clean components. Only clean them with a dry cloth.

- SST

- 09890-47010 ( 09891-04010, 09891-04020, 09891-04030, 09891-04040 )

-

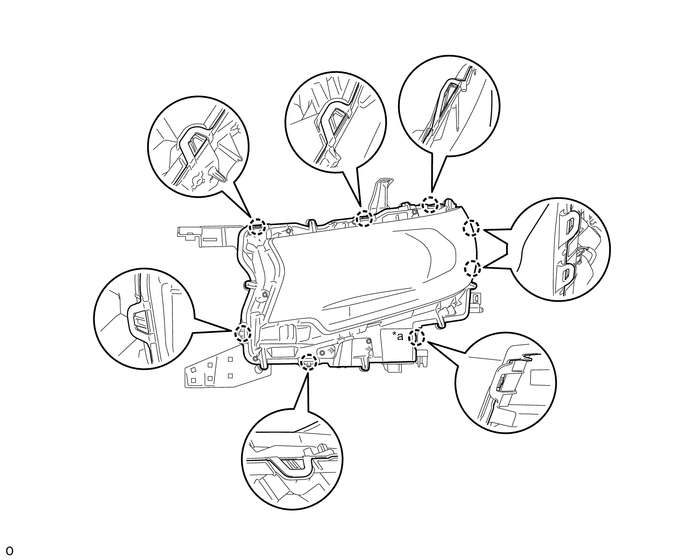

Remove the 7 screws.

-

Using a T20H "TORX" driver, remove the "TORX" screw.

*a "TORX" Screw - - -

*a Matchmark *b Unlock Position Mark Turn the connector cover counterclockwise until the matchmark is aligned with the unlock position mark to remove the connector cover.

-

Disconnect the connector.

-

Remove the headlight lens LH:

Tech Tips

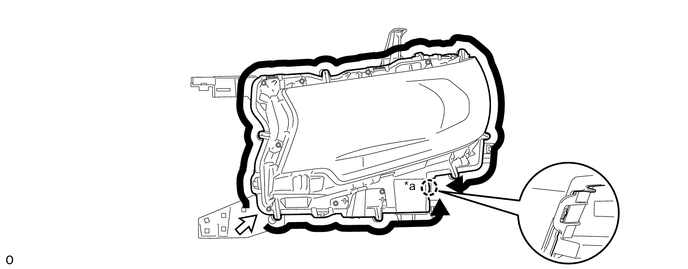

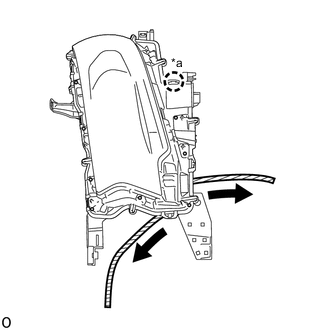

Remove the headlight lens LH from the headlight housing from the separation starting point toward the base point claw as shown in the illustration.

*a Base Point Claw - -

Separation Starting Point - -

-

Detach the 7 claws.

Tech Tips

It is not necessary to detach the claw at the base point as the claw is detached in the later step.

*a Base Point Claw - - -

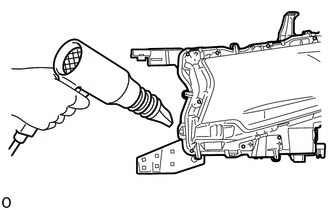

Using a dryer, warm the headlight lens gasket from the backside of the headlight assembly LH at the separation starting point of the headlight lens LH.

Note

If the headlight is heated unevenly, it will deform or melt.

-

Insert a finger between the headlight lens LH and headlight housing and lift up the headlight lens LH.

-

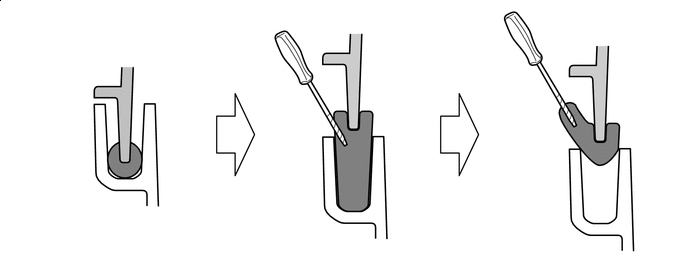

Using a screwdriver, pull out the headlight lens gasket through the opening.

Note

Do not damage the groove in the headlight housing or the surface of the headlight lens LH.

Tech Tips

Tape the screwdriver tip before use.

Headlight Lens Gasket

Headlight Lens LH

Headlight Housing

Protective Tape -

*a Base Point Claw

Headlight Lens Gasket While lifting up the headlight lens LH, pull out the headlight lens gasket until it reaches the base point claw.

Tech Tips

If the headlight lens gasket is disconnected while being pulled out, lift up the headlight lens and pull the headlight lens gasket again.

-

Detach the base point claw and remove the headlight lens LH.

*a Base Point Claw - -

-

-

-

REMOVE HEADLIGHT LENS GASKET

Note

-

The headlight lens gasket must not be reused.

-

Perform work using clean rubber gloves.

-

Do not touch the inner surface of the lens and metallic surfaces as much as possible, or they may become dirty.

-

Do not allow metallic surfaces to become dirty, as such surfaces become damaged even if they are only lightly wiped with a soft cloth.

-

If there are fingerprints on the inner surface of the lens, lightly wiped with a soft cloth.

-

Do not use solvent to clean components. Only clean them with a dry cloth.

-

Remove the remaining headlight lens gasket from the headlight lens and headlight housing.

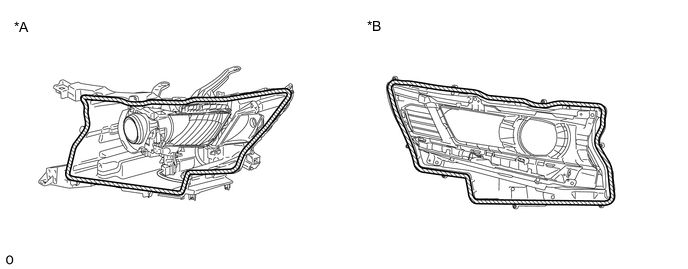

*A Headlight Housing Side *B Headlight Lens LH Side

Headlight Lens Gasket - -

-

-

REMOVE HEADLIGHT UNIT ASSEMBLY LH

Note

-

Prevention of static electricity is required during this procedure.

-

Use static electricity countermeasures SST (desktop anti-static mat set) and observe all precautions to prevent damage to the system by electrostatic discharge (ESD).

-

Perform work using clean rubber gloves.

-

Do not touch the headlight unit assembly LH with bare hands.

-

Do not allow metallic surfaces to become dirty, as such surfaces become damaged even if they are only lightly wiped with a soft cloth.

-

If there are fingerprints on the inner surface of the lens, lightly wiped with a soft cloth.

-

Do not use solvent to clean components. Only clean them with a dry cloth.

- SST

- 09890-47010 ( 09891-04010, 09891-04020, 09891-04030, 09891-04040 )

-

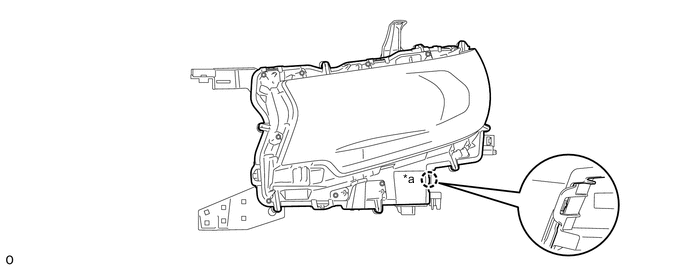

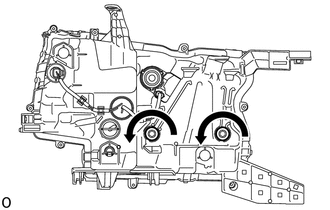

Using a vernier caliper, measure and record the dimensions of the protrusion and retraction of the aiming screw.

*a Protrusion and Retraction Amount Measurement Area - - -

Disconnect the connector.

-

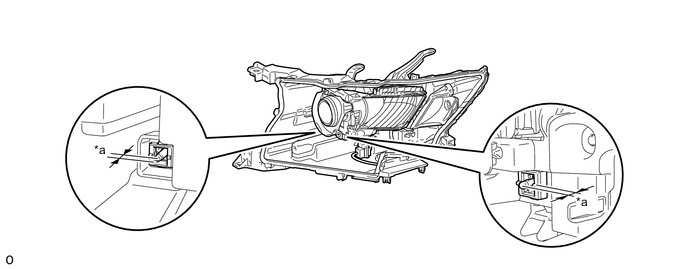

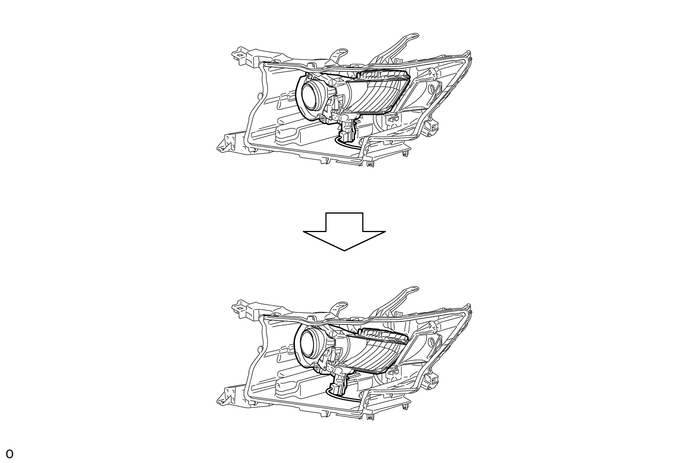

While holding the headlight unit assembly LH with one hand so that it does not fall over, loosen the vertical aiming screw and horizontal aiming screw until the headlight unit assembly LH is disconnected.

-

Lift up the bottom side of the headlight unit assembly LH and disconnect and remove it from the headlight leveling motor LH as shown in the illustration.

-

-

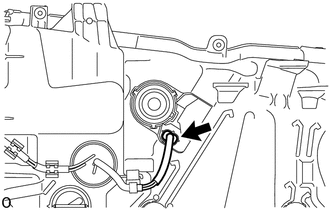

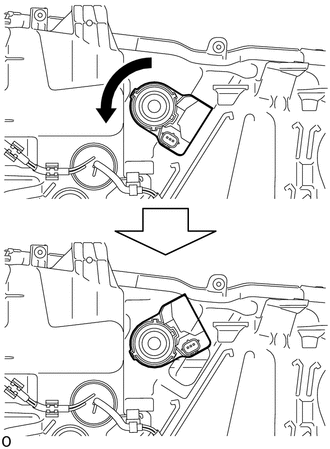

REMOVE HEADLIGHT LEVELING MOTOR LH

-

Disconnect the connector.

-

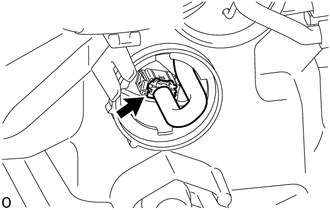

Turn the headlight leveling motor LH counterclockwise until it stops and remove the headlight leveling motor LH.

Tech Tips

For the headlight assembly RH, turn the headlight leveling motor RH clockwise to remove it.

-

-

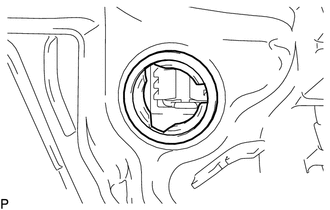

REMOVE HEADLIGHT LEVELING MOTOR BASE PACKING

-

Remove the headlight leveling motor base packing.

Note

The headlight leveling motor base packing must not be reused.

-