GENERATOR REASSEMBLY

-

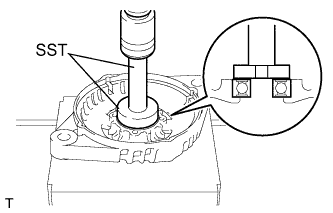

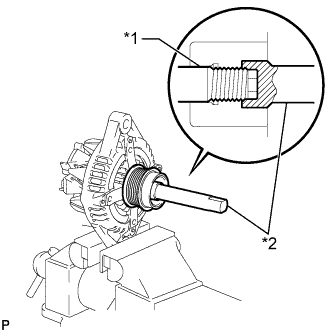

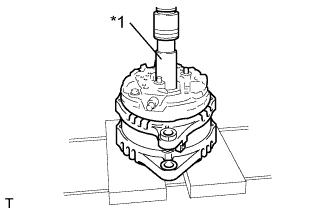

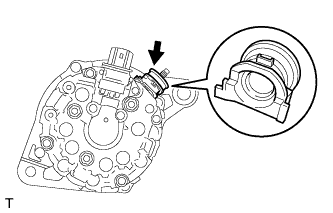

INSTALL GENERATOR DRIVE END FRAME BEARING

-

Using SST and a press, press in a new generator drive end frame bearing.

- SST

- 09950-60010 ( 09951-00470 )

- 09950-70010 ( 09951-07100 )

-

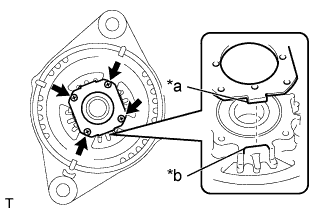

Text in Illustration *a Tab *b Cutout Fit the tabs on the retainer plate into the cutouts on the drive end frame to install the retainer plate.

-

Install the 4 screws.

- Torque:

- 2.3 N*m { 23 kgf*cm, 20 in.*lbf }

-

-

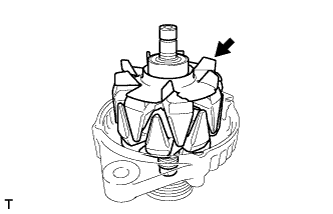

INSTALL GENERATOR ROTOR ASSEMBLY

-

Place the drive end frame on the generator pulley with clutch.

-

Install the generator rotor assembly to the drive end frame.

-

-

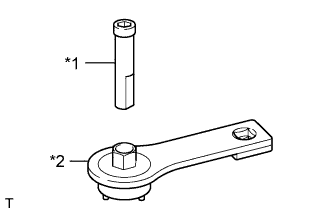

INSTALL GENERATOR PULLEY WITH CLUTCH

-

Temporarily install the generator pulley with clutch onto the rotor shaft.

-

Mount the generator drive end frame in a vise tightly.

-

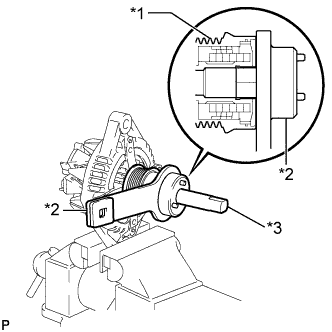

Text in Illustration *1 SST (A) *2 SST (B) Confirm SST (A) and (B) shown in the illustration.

- SST

- 09820-63021

-

Text in Illustration *1 Rotor Shaft *2 SST (A) Place the rotor shaft end into SST (A).

-

Text in Illustration *1 Generator Pulley with Clutch *2 SST (B) *3 SST (A) Fit SST (B) to the generator pulley with clutch.

-

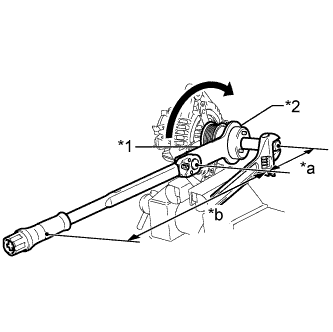

Text in Illustration *1 SST (B) *2 SST (A) *a Fulcrum Length

100 mm (3.94 in.)

*b Fulcrum Length

255 mm (10.04 in.)

Tighten the pulley by turning SST (B) in the direction shown in the illustration.

- Torque:

- without SST

- 80 N*m { 816 kgf*cm, 59 ft.*lbf }

- with SST

- 57 N*m { 581 kgf*cm, 42 ft.*lbf }

Note

-

The "with SST" torque value is effective when using SST with a fulcrum length of 100 mm (3.94 in.) and a torque wrench with a fulcrum length of 255 mm (10.04 in.) Click here.

-

The "with SST" torque value is effective when SST is parallel to the torque wrench.

-

Check that the drive end frame is secured in the vise tightly.

-

Hold SST (A) tightly during the operation.

-

Remove SST from the generator assembly.

-

Check that the generator pulley with clutch rotates smoothly.

-

Install a new generator pulley cap to the generator pulley with clutch.

-

-

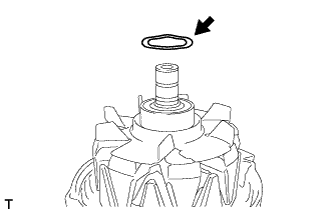

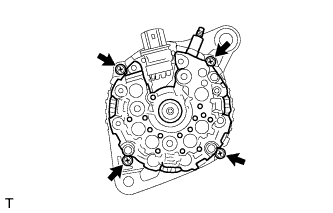

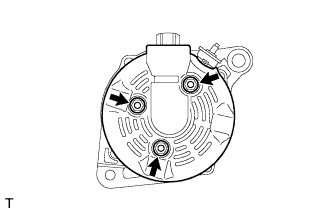

INSTALL GENERATOR COIL ASSEMBLY

-

Place a new generator washer on the generator rotor.

-

Text in Illustration *1 Deep Socket Wrench (21 mm) Using a deep socket wrench (21 mm) and a press, slowly press in the generator coil assembly.

-

Install the 4 bolts.

- Torque:

- 5.9 N*m { 60 kgf*cm, 52 in.*lbf }

-

-

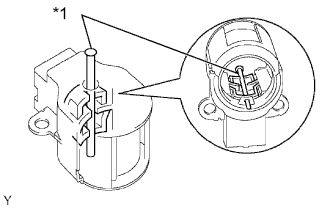

INSTALL GENERATOR BRUSH HOLDER ASSEMBLY

-

Text in Illustration *1 Pin While pushing the 2 brushes into the generator brush holder assembly, insert a 1.0 mm (0.0394 in.) pin into the brush holder hole.

-

Text in Illustration *1 Pin Install the brush holder assembly to the generator coil with the 2 screws.

- Torque:

- 1.8 N*m { 18 kgf*cm, 16 in.*lbf }

-

Pull out the pin from the generator brush holder.

-

-

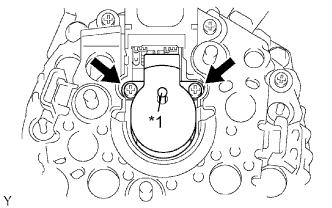

INSTALL GENERATOR TERMINAL INSULATOR

-

Install the generator terminal insulator to the generator coil.

Note

Be sure to install the terminal insulator in the correct direction.

-

-

INSTALL GENERATOR REAR END COVER

-

Install the generator rear end cover to the generator coil with the 3 nuts.

- Torque:

- 4.6 N*m { 47 kgf*cm, 41 in.*lbf }

-