HEADLIGHT LEVELING SWITCH INSPECTION

PROCEDURE

-

INSPECT HEADLIGHT LEVELING SWITCH

-

Voltage Ratio Inspection.

-

Disconnect connector H135 from the headlight leveling switch.

-

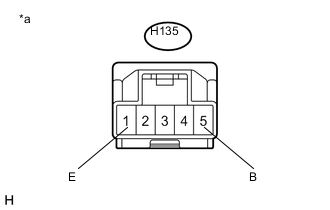

Text in Illustration *a Front side of wire harness connector

(to Headlight Leveling Switch)

Using SST, measure the voltage between terminals H135-5 (B) and H135-1 (E). (Voltage A)

-

Connect connector H135 to the headlight leveling switch.

-

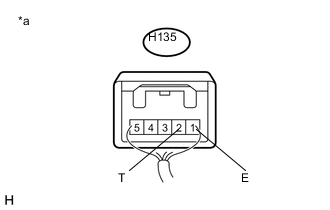

Text in Illustration *a Component with harness connected

(Headlight Leveling Switch)

Using SST, measure the voltage between terminals H135-2 (T) and H135-1 (E) from backside of the connector. (Voltage B)

-

Divide Voltage B by Voltage A to obtain the voltage ratio.

Standard Voltage Ratio Switch Position Voltage Ratio (%) 0 7 to 13 (0.5) 12.3 to 18.3 1 17.7 to 23.7 (1.5) 23.0 to 29.0 2 28.3 to 34.3 (2.5) 33.7 to 39.7 3 39.0 to 45.0 (3.5) 44.7 to 50.3 4 49.7 to 55.7 (4.5) 55.0 to 61.0 5 60.3 to 66.3 Tech Tips

If Voltage A is 12 V and Voltage B is 10 V, the voltage ratio (10/12=0.83) will be 83.3%.

If the result is not as specified, replace the headlight leveling switch.

-

-

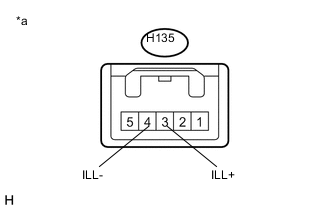

Text in Illustration *a Connector disconnected

(to Headlight Leveling Switch)

LED Illumination Inspection

-

Connect the negative and positive battery terminals to the connector according to the table below.

Tester Connection Switch Condition Specified Condition 3 (ILL+) - 4 (ILL-) Battery positive (+) a 3 (ILL+)

Battery negative (-) a 4 (ILL-)

Illuminates

-

-