MANUAL TRANSMISSION UNIT REASSEMBLY

-

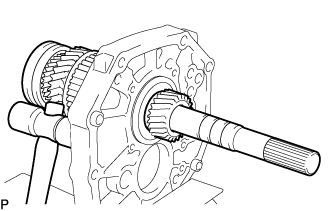

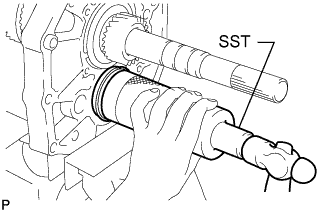

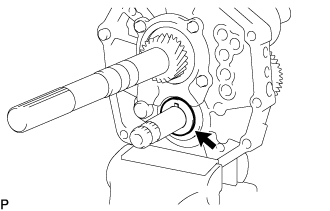

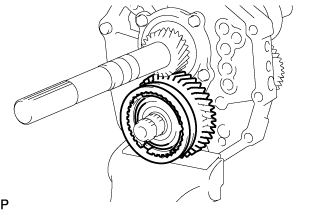

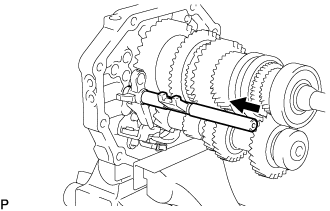

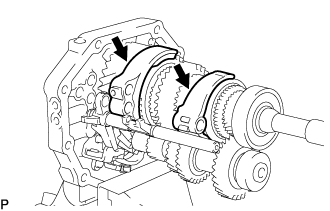

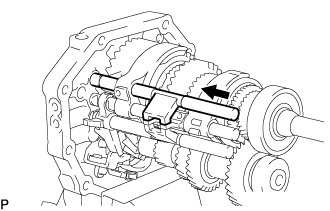

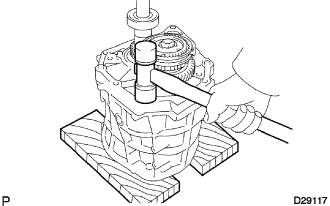

INSTALL OUTPUT SHAFT ASSEMBLY

-

Apply gear oil to the sliding part of the output shaft assembly.

-

Using a plastic-faced hammer, install the output shaft assembly by tapping the intermediate plate.

-

-

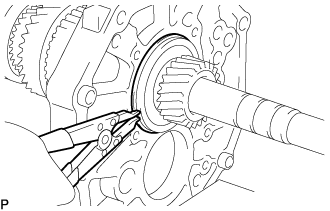

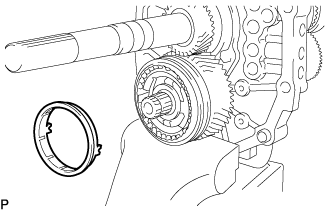

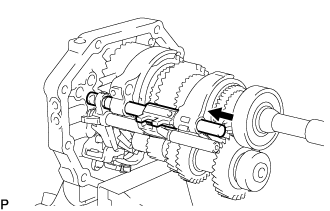

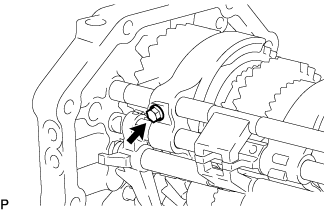

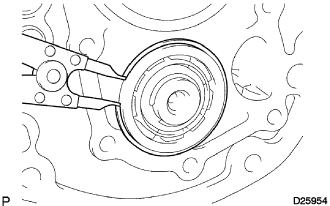

INSTALL OUTPUT SHAFT BEARING SHAFT SNAP RING

-

Using a snap ring expander, install the output shaft bearing shaft snap ring to the output shaft assembly.

-

-

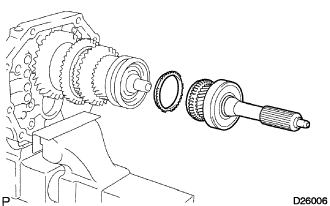

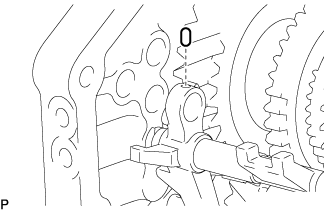

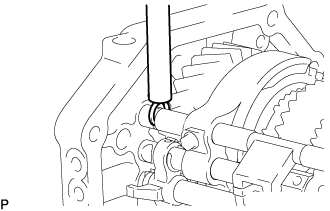

INSTALL INPUT SHAFT ASSEMBLY

-

Apply gear oil to the input shaft assembly and No. 2 synchronizer ring, and install them to the output shaft assembly.

Note

-

Make sure that the No. 2 synchromesh shifting key fits into the grooves of the No. 2 synchronizer ring.

-

Check that the input shaft assembly rotates smoothly.

-

-

-

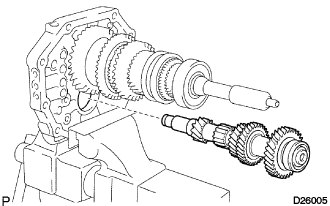

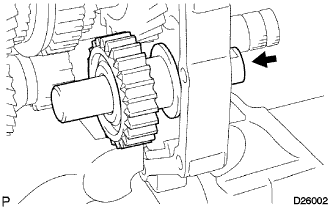

INSTALL COUNTER GEAR

-

Temporarily install the counter gear to the intermediate plate.

-

-

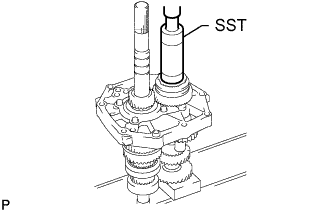

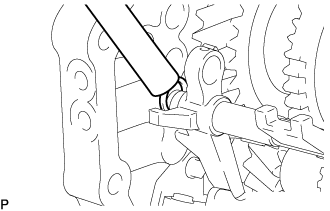

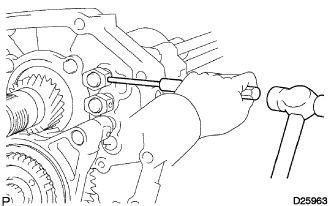

INSTALL COUNTER SHAFT CENTER BEARING

-

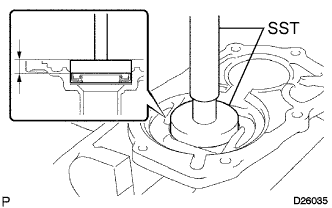

Using SST and a hammer, install a new counter shaft center bearing to the intermediate plate.

- SST

- 09316-60011 ( 09316-00011 )

Tech Tips

Install the bearing while tapping the tip of the counter gear with a plastic-faced hammer so that the counter gear does not hit the side wall of the output shaft gear by being pushed forward.

-

Using a snap ring expander, install the snap ring.

-

-

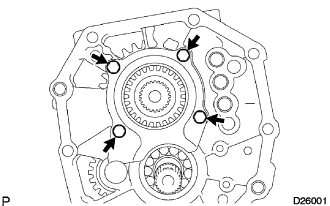

INSTALL REVERSE IDLER GEAR SUB-ASSEMBLY

-

Apply gear oil to each sliding part of the reverse idler gear sub-assembly and the reverse idler gear shaft, and install them to the intermediate plate.

Note

Orient the groove side of the reverse idler shaft to the rear side and install it from the rear side.

-

-

INSTALL OUTPUT SHAFT REAR BEARING(MTM) RETAINER

-

Install the output shaft rear bearing (MTM) retainer into the groove of the reverse idler gear shaft with the 4 bolts.

- Torque:

- 18 N*m { 184 kgf*cm, 13 ft.*lbf }

-

-

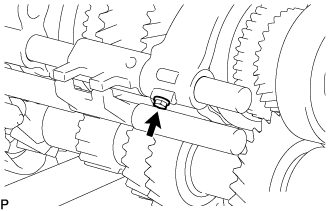

INSTALL 5TH GEAR THRUST WASHER PIN

-

Apply MP grease to the 5th gear thrust washer pin, and install it to the counter gear.

-

-

INSTALL 5TH GEAR THRUST WASHER

-

Apply gear oil to the 5th gear thrust washer, and install it to the counter gear.

Note

Install the thrust washer so that its chamfer side faces to the front side.

-

-

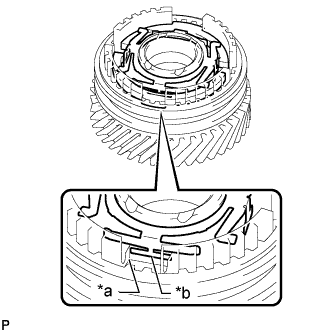

INSTALL NO. 3 SYNCHROMESH SHIFTING KEY

-

Apply gear oil to the sliding part of the No. 3 transmission hub sleeve, and install it to the counter shaft 5th gear.

Note

Be sure of the direction of the No. 3 transmission hub sleeve and the counter shaft 5th gear.

-

Text in Illustration *a Cutout *b Protrution Install the 2 No. 3 synchromesh shifting keys and No. 3 synchromesh shifting key spring to the counter shaft 5th gear as shown in the illustration.

Tech Tips

When installing the No. 3 synchromesh shifting key spring, make sure the protrusion fits into the cutout.

-

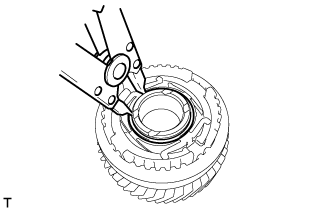

Using a snap ring expander, install the shaft snap ring to the counter shaft 5th gear.

-

-

INSTALL COUNTER 5TH GEAR BEARING

-

Apply gear oil to the counter 5th gear bearing and install it to the counter shaft 5th gear.

-

-

INSTALL COUNTER SHAFT 5TH GEAR

-

Apply gear oil to the counter 5th gear and No. 3 transmission hub sleeve assembly, and install them to the counter gear.

-

-

INSTALL OUTER NO.3 SYNCHRONIZER RING

-

Apply gear oil to the outer No. 3 synchronizer ring, and install it to the counter gear.

Note

Make sure that the No. 3 synchromesh shifting key fits into the grooves of the outer No. 3 synchronizer ring.

-

-

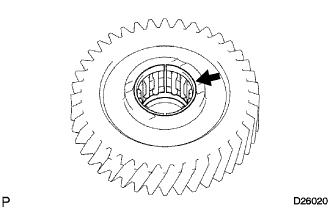

INSTALL No. 5 GEAR SPLINE PIECE

-

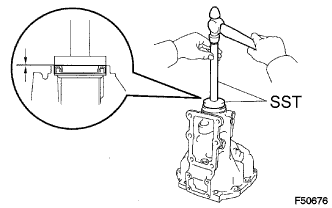

Using SST and a press, install the No. 5 gear spline piece to the counter gear.

- SST

- 09316-60011 ( 09316-00011 )

Note

Check that the gear rotates smoothly.

-

-

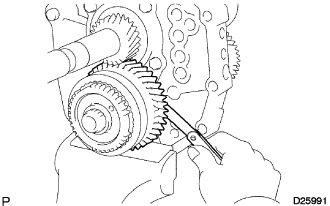

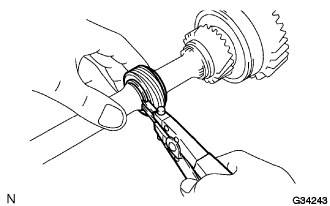

INSTALL COUNTER GEAR REAR SHAFT SNAP RING

-

Select a counter gear rear shaft snap ring so that the thrust gap between the No. 5 gear spline piece and counter gear rear shaft snap ring is within the specified values. Use a brass bar and a hammer, install it to the counter gear.

Standard clearance 0.1 mm (0.0039 in.) or less Mark Thickness: mm (in.) A 2.80 to 2.85 (0.1102 to 0.1122) B 2.85 to 2.90 (0.1122 to 0.1141) C 2.90 to 2.95 (0.1141 to 0.1160) D 2.95 to 3.00 (0.1160 to 0.1181) E 3.00 to 3.05 (0.1181 to 0.1200) F 3.05 to 3.10 (0.1200 to 0.1220) G 3.10 to 3.15 (0.1220 to 0.1240)

-

-

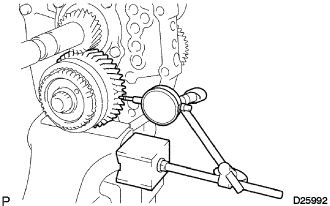

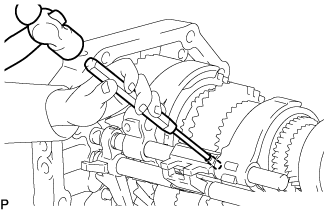

INSPECT COUNTER SHAFT 5TH GEAR THRUST CLEARANCE

-

Using a feeler gauge, measure the counter shaft 5th gear thrust clearance.

Standard clearance 0.10 to 0.35 mm (0.0039 to 0.0138 in.)

-

-

INSPECT COUNTER SHAFT 5TH GEAR RADIAL CLEARANCE

-

Using a dial indicator, measure the radial clearance of the counter shaft 5th gear.

Standard clearance 0.015 to 0.068 mm (0.0059 to 0.0027 in.) If the clearance is not within the specified values, replace the counter 5th gear bearing with a new one.

-

-

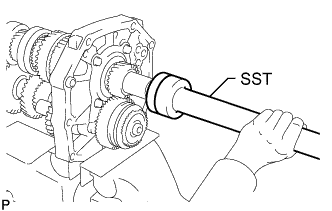

INSTALL OUTPUT SHAFT REAR BEARING

-

Using SST and a press, install a new output shaft rear bearing and output shaft spacer to the output shaft.

- SST

- 09309-35010

-

-

INSTALL OUTPUT SHAFT BEARING SHAFT SNAP RING

-

Select an output shaft bearing shaft snap ring so that the thrust gap between the snap ring and the bearing is within the specified values. Use a brass bar and a hammer to install it to the output shaft assembly.

Standard clearance 0.1 mm (0.0039 in.) or less Mark Thickness: mm (in.) A 2.65 to 2.70 (0.1043 to 0.1063) B 2.70 to 2.75 (0.1063 to 0.1083) C 2.75 to 2.80 (0.1083 to 0.1102) D 2.80 to 2.85 (0.1102 to 0.1122) E 2.85 to 2.90 (0.1122 to 0.1141) F 2.90 to 2.95 (0.1141 to 0.1160) G 2.95 to 3.00 (0.1160 to 0.1181) H 3.00 to 3.05 (0.1181 to 0.1200) J 3.05 to 3.10 (0.1200 to 0.1220) K 3.10 to 3.15 (0.1220 to 0.1240) L 3.15 to 3.20 (0.1240 to 0.1260) M 3.20 to 3.25 (0.1260 to 0.1280) N 3.25 to 3.30 (0.1280 to 0.1299) P 3.30 to 3.35 (0.1299 to 0.1319) Q 3.35 to 3.40 (0.1319 to 0.1339) R 3.40 to 3.45 (0.1339 to 0.1358) S 3.45 to 3.50 (0.1358 to 0.1378)

-

-

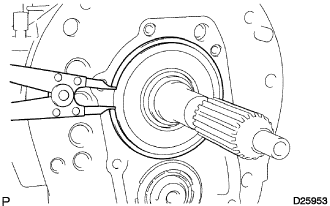

INSTALL SPEEDOMETER DRIVE (MTM) GEAR

-

Using snap ring expander, install the snap ring.

-

Install the steel ball and speedometer drive (MTM) gear.

-

Using snap ring expander, install the snap ring.

-

-

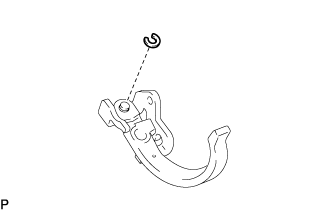

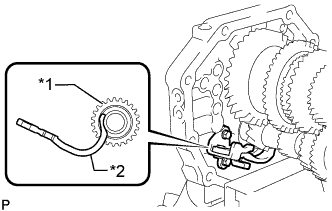

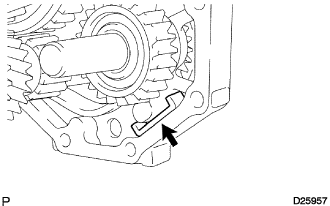

INSTALL REVERSE SHIFT ARM BRACKET

-

Install the reverse shift arm to the reverse shift arm bracket with a new snap ring.

-

Text in Illustration *1 Reverse Idler Gear *2 Reverse Shift Arm Insert the tip of the reverse shift arm into the reverse idler gear.

-

Install the reverse shift arm bracket with the 2 bolts.

- Torque:

- 18 N*m { 184 kgf*cm, 13 ft.*lbf }

-

Install the torsion spring to the reverse shift arm bracket.

Note

Make sure that the torsion spring is securely installed to the reverse shift arm.

-

-

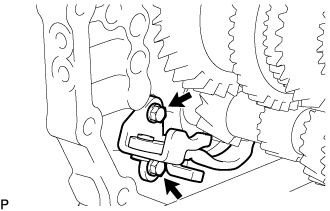

INSTALL REVERSE SHIFT FORK

-

Install the reverse shift fork to the reverse shift arm.

-

-

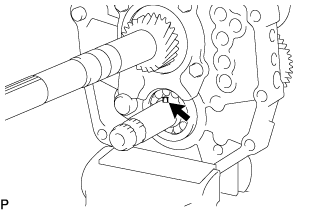

INSTALL REVERSE SHIFT FORK SHAFT

-

Install the No. 3 gear shift fork to the No. 3 transmission hub sleeve and the reverse shift fork shaft to the intermediate plate from the front side.

-

Install the straight pin to the reverse shift fork.

-

Using a brass bar and a hammer, install the snap ring to the reverse shift fork shaft.

-

Using a 5 mm pin punch and a hammer, install the slotted spring pin into the No. 3 gear shift fork.

-

-

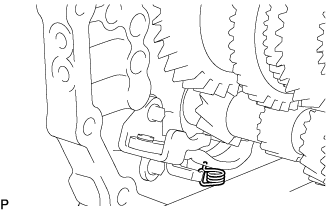

INSTALL NO. 2 GEAR SHIFT FORK SHAFT

-

Install the No. 1 shift interlock roller to the intermediate plate.

-

Install the No. 1 gear shift fork to the reverse gear.

-

Install the No. 2 gear shift fork to the No. 2 transmission hub sleeve.

-

Install the No. 2 gear shift head and No. 2 gear shift fork shaft to the intermediate plate from the front side.

-

Using a 5 mm pin punch and a hammer, install the slotted spring pin into the No. 2 gear shift fork shaft.

-

Install a new bolt to the No. 2 gear shift fork.

- Torque:

- 20 N*m { 199 kgf*cm, 14 ft.*lbf }

-

Using a brass bar and a hammer, install the snap ring to the No. 2 gear shift fork shaft.

-

-

INSTALL SHIFT FORK SHAFT STOPPER

-

Install the shift fork shaft stopper to the No. 2 gear shift fork shaft.

-

Using a 5 mm pin punch and a hammer, install the slotted spring pin into the No. 2 gear shift fork shaft.

-

-

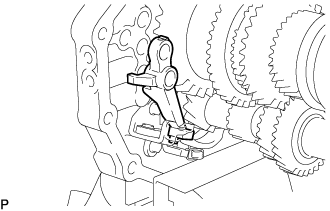

INSTALL NO. 1 GEAR SHIFT FORK SHAFT

-

Install the shift interlock pin and No. 1 shift interlock roller into the intermediate plate.

-

Apply gear oil to the No. 1 gear shift fork shaft, and install it to the intermediate plate from the front side.

-

Install a new bolt to the No. 1 gear shift fork.

- Torque:

- 20 N*m { 199 kgf*cm, 14 ft.*lbf }

-

Using a brass bar and a hammer, install the snap ring to the No. 1 gear shift fork shaft.

-

-

INSTALL SHIFT FORK SHAFT STOPPER

-

Install the shift fork shaft stopper to the No. 1 gear shift fork shaft.

-

Using a 5 mm pin punch and a hammer, install the slotted spring pin into the No. 2 gear shift fork shaft.

-

-

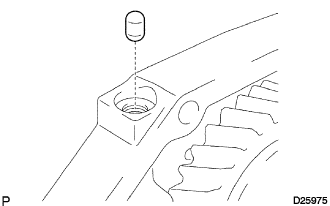

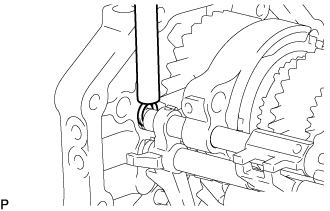

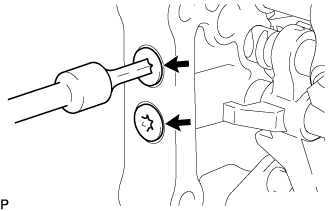

INSTALL NO. 1 SHIFT DETENT BALL SPRING SEAT

-

Install the 2 compression springs and 2 shift detent balls into the intermediate plate.

-

Using a T40 "TORX" socket wrench, install the 2 No. 1 shift detent ball spring seats to the intermediate plate.

- Torque:

- 19 N*m { 189 kgf*cm, 14 ft.*lbf }

-

Install the shift detent ball and compression spring into the intermediate plate.

-

Using a T40 "TORX" socket wrench, install the No. 1 shift detent ball spring seat to the intermediate plate.

- Torque:

- 19 N*m { 189 kgf*cm, 14 ft.*lbf }

-

-

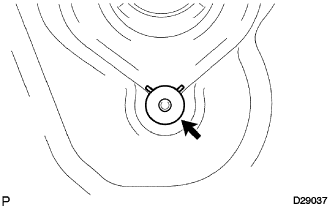

INSTALL TRANSMISSION MAGNET

-

Clean the transmission magnet, and install it to the intermediate plate.

-

-

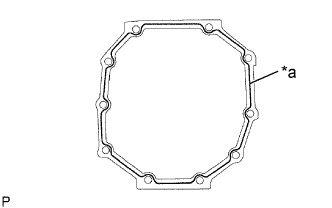

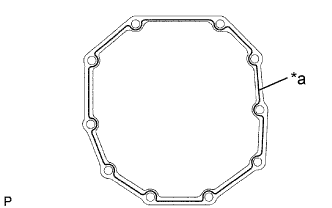

INSTALL MANUAL TRANSMISSION CASE

-

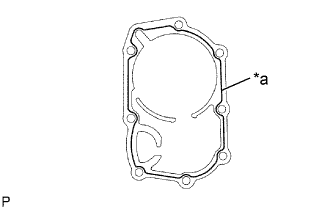

Text in Illustration *a Seal Packing Apply seal packing to the manual transmission case as shown in the illustration.

Seal packing Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent Seal diameter 1.2 mm (0.0472 in.) Note

Assemble parts within 10 minutes of application. Otherwise, the packing (FIPG) material must be removed and reapplied.

-

Using a plastic-faced hammer, tap the manual transmission case to attach it to the intermediate plate.

-

-

INSTALL NO. 1 COUNTER GEAR FRONT BEARING SNAP RING

-

Using a snap ring expander, install the No. 1 counter gear front bearing snap ring to the manual transmission case.

-

-

INSTALL FRONT BEARING SHAFT SNAP RING

-

Using a snap ring expander, install the front bearing shaft snap ring to the manual transmission case.

-

-

INSTALL FRONT TRANSMISSION BEARING RETAINER OIL SEAL

-

Using SST and a hammer, install a new front transmission bearing retainer oil seal to the front bearing retainer.

- SST

- 09950-60010 ( 09951-00300, 09951-00520, 09952-06010, 09951-07100 )

Drive in depth 11.2 to 12.2 mm (0.4409 to 0.4803 in.) -

Coat the lip of the transmission front bearing retainer oil seal with MP grease.

-

-

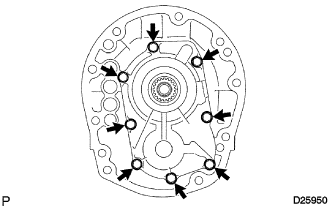

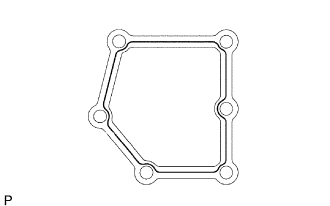

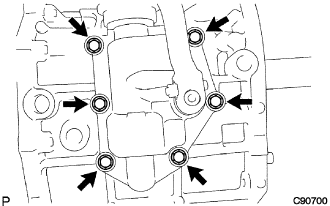

INSTALL FRONT BEARING RETAINER (MTM)

-

Text in Illustration *a Seal Packing Apply seal packing to the front bearing retainer (MTM) as shown in the illustration.

Seal packing Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent Seal diameter 1.2 mm (0.0472 in.) Note

Assemble parts within 10 minutes of application. Otherwise, the packing (FIPG) material must be removed and reapplied.

-

Apply seal packing to the bolts.

Seal packing Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent -

Install the front bearing retainer (MTM) to the manual transmission case with the 8 bolts.

- Torque:

- 17 N*m { 168 kgf*cm, 12 ft.*lbf }

Check that the input shaft and output shaft rotate smoothly.

-

-

INSTALL MANUAL TRANSMISSION EXTENSION HOUSING OIL SEAL

-

Using SST and a hammer, install a new manual transmission extension housing oil seal to the extension housing sub-assembly.

- SST

- 09710-30050

- 09950-70010 ( 09951-07100 )

Drive in depth -0.5 to 0.5 mm (-0.020 to 0.020 in.) Note

Be careful not to damage the oil seal lip.

-

Lightly apply MP grease to the tip of the manual transmission extension housing oil seal.

-

-

INSTALL EXTENSION HOUSING OIL RECEIVER PIPE

-

Install the extension housing oil receiver pipe with the bolt.

- Torque:

- 11 N*m { 112 kgf*cm, 8 ft.*lbf }

-

-

INSTALL No. 1 EXTENSION HOUSING OIL RECEIVER PIPE

-

Install the No. 1 extension housing oil receiver pipe to the extension (MTM) housing sub-assembly.

-

-

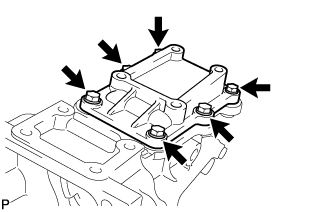

INSTALL EXTENSION (MTM) HOUSING SUB-ASSEMBLY

-

Text in Illustration *a Seal Packing Apply seal packing to the extension (MTM) housing sub-assembly as shown in the illustration.

Seal packing Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent Seal diameter 1.2 mm (0.0472 in.) Note

Assemble parts within 10 minutes of application. Otherwise, the packing (FIPG) material must be removed and reapplied.

-

Install the extension (MTM) housing sub-assembly to the manual transmission case with the 10 bolts.

- Torque:

- 37 N*m { 377 kgf*cm, 27 ft.*lbf }

-

-

INSTALL SHIFT LEVER SHAFT HOUSING SUB-ASSEMBLY

-

Apply seal packing to the shift lever shaft housing sub-assembly as shown in the illustration.

Seal packing Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent -

Install the shift lever shaft housing sub-assembly to the manual transmission case with the 6 bolts.

- Torque:

- 17 N*m { 168 kgf*cm, 12 ft.*lbf }

-

-

INSTALL EXTENSION HOUSING DUST(MTM) DEFLECTOR

-

Using a plastic-faced hammer, install the extension housing dust (MTM) deflector to the extension (MTM) housing sub-assembly.

-

-

INSTALL EXTENSION HOUSING(MTM) COVER

-

Install the extension housing (MTM) cover and a new gasket to the extension (MTM) housing sub-assembly with the 6 bolts.

- Torque:

- 18 N*m { 183 kgf*cm, 13 ft.*lbf }

-

-

INSTALL SPEEDOMETER SENSOR

-

Install a new O-ring to the speedometer sensor.

-

Install the speedometer sensor with the bolt.

- Torque:

- 11 N*m { 112 kgf*cm, 8 ft.*lbf }

-

-

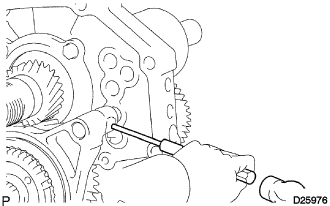

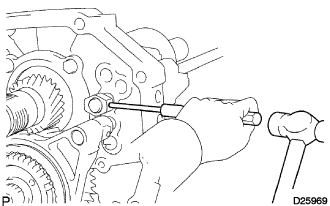

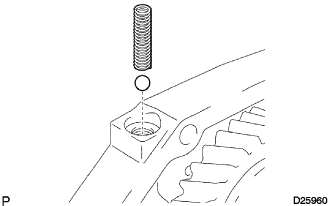

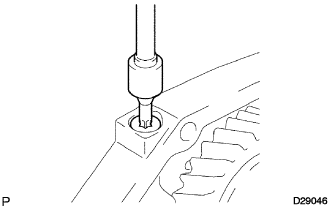

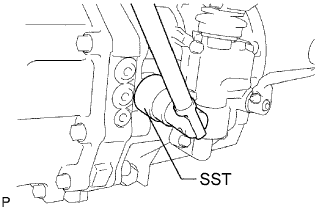

INSTALL BACK UP LIGHT SWITCH ASSEMBLY

-

Using SST, install the back up light switch assembly and a new gasket to the manual transmission case.

- SST

- 09817-16011

- Torque:

- 44 N*m { 448 kgf*cm, 32 ft.*lbf }

-

-

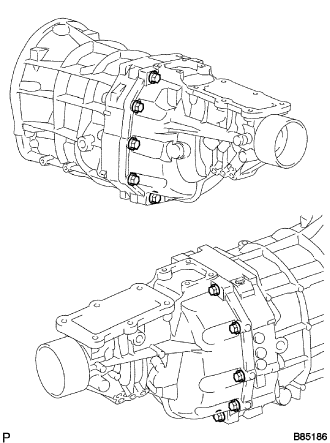

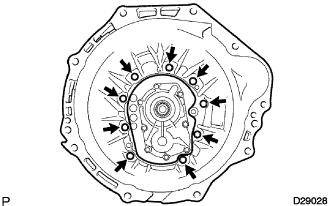

INSTALL CLUTCH HOUSING

-

Install the clutch housing to the manual transmission case with the 9 bolts.

- Torque:

- 36 N*m { 367 kgf*cm, 27 ft.*lbf }

-

-

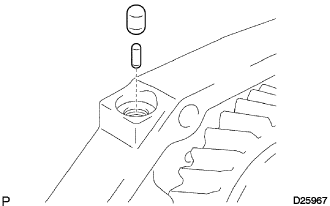

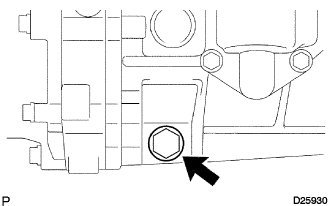

INSTALL MANUAL TRANSMISSION DRAIN PLUG

-

Install the manual transmission drain plug to the manual transmission case through a new gasket.

- Torque:

- 37 N*m { 377 kgf*cm, 27 ft.*lbf }

-

-

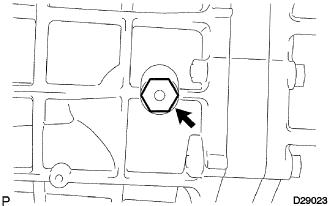

INSTALL MANUAL TRANSMISSION FILLER PLUG

-

Install the manual transmission filler plug to the manual transmission case through a new gasket.

- Torque:

- 37 N*m { 377 kgf*cm, 27 ft.*lbf }

-