ENTRY AND START SYSTEM(for Start Function) Power Source Mode does not Change to ON (IG and ACC)

DESCRIPTION

When the engine switch is pushed with the key in the cabin, the power management control ECU receives signals to switch the power source mode.

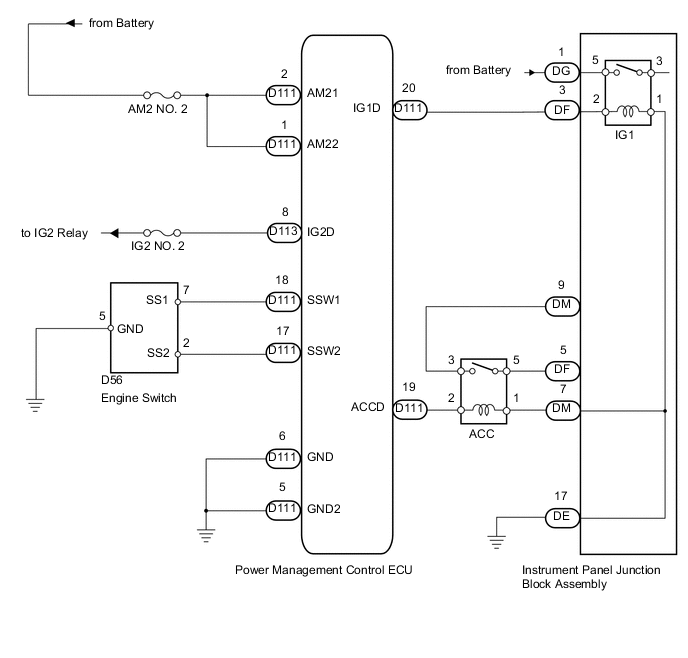

WIRING DIAGRAM

CAUTION / NOTICE / HINT

Note

-

When using the intelligent tester with the engine switch off to troubleshoot: Connect the intelligent tester to the vehicle, and turn a courtesy light switch on and off at 1.5 second intervals until communication between the intelligent tester and vehicle begins.

-

Before performing the inspection, check that there are no problems related to the CAN communication system and LIN communication system.

-

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

-

CHECK HARNESS AND CONNECTOR (BATTERY - POWER MANAGEMENT CONTROL ECU)

-

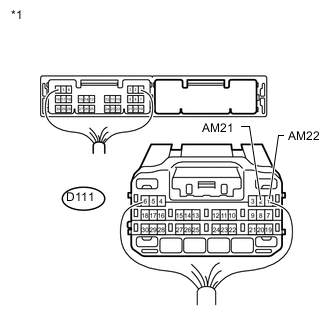

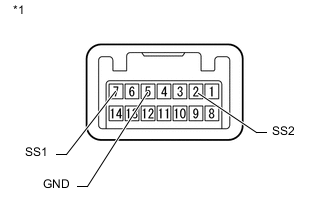

Text in Illustration *1 Rear view of wire harness connector

(to Power Management Control ECU)

Disconnect the D111 power management control ECU connector.

-

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Condition Specified Condition D111-2 (AM21) - Body ground Always 9.5 to 16 V D111-1 (AM22) - Body ground

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK HARNESS AND CONNECTOR (POWER MANAGEMENT CONTROL ECU - BODY GROUND)

-

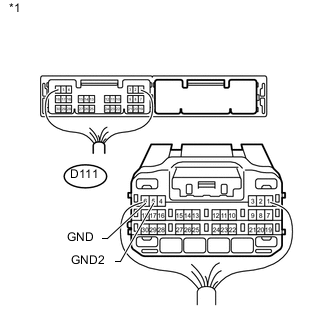

Disconnect the D111 power management control ECU connector.

-

Text in Illustration *1 Rear view of wire harness connector

(to Power Management Control ECU)

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition D111-6 (GND) - Body ground Always Below 1 Ω D111-5 (GND2) - Body ground

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

READ VALUE USING INTELLIGENT TESTER (KEY CERTIFICATION WAITING TIMED OUT)

-

Connect the intelligent tester to the DLC3.

-

Turn the intelligent tester on.

Tech Tips

When using the intelligent tester with the engine switch off, turn on and off any of the door courtesy light switches repeatedly at intervals of 1.5 seconds or less until communication between the tester and vehicle starts.

-

Enter the following menus: Body / Power Source Control / Data List.

-

Read the Data List and check that "No" is displayed 1 second after turning the engine switch from off to on (IG).

Power Source Control Tester Display Measurement Item/Range Normal Condition Diagnostic Note Key Certification Waiting Timed Out Key certification waiting timed out / Yes or No Yes: Key certification waiting timed out

No: Key certification completed within specified time

- OK "No" is displayed 1 second after turning the engine switch from off to on (IG).

NG

CHECK FOR DTC Click here

OK

-

-

READ VALUE USING INTELLIGENT TESTER (START SWITCH 1, 2)

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the intelligent tester on.

-

Enter the following menus: Body / Power Source Control / Data List.

-

According to the display on the intelligent tester, read the Data List.

Power Source Control Tester Display Measurement Item/Range Normal Condition Diagnostic Note Start Switch 1 Start Switch 1 / ON or OFF ON: Engine switch pushed

OFF: Engine switch not pushed

- Start Switch 2 Start Switch 2 / ON or OFF ON: Engine switch pushed

OFF: Engine switch not pushed

- OK The display changes in response to the operation of the engine switch.

NG

INSPECT ENGINE SWITCH Click here

OK

-

-

CHECK POWER MANAGEMENT CONTROL ECU

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the intelligent tester on.

-

Enter the following menus: Body / Power Source Control/ Data List.

-

Read the Data List and check that the display changes according to the changes in the power source mode when the engine switch is pushed.

Power Source Control Tester Display Measurement Item/Range Normal Condition Diagnostic Note Power Supply Condition Power Supply Condition / IG2 ON, ST ON, All OFF, IG ON or ACC ON IG2 ON: IG2 relay on

ST ON: ST request signal on

All OFF: All relays off

IG1 ON: IG1 relay on

ACC ON: ACC relay on

- OK Display changes according to the changes in the power source mode when the engine switch is pushed. -

Measure the voltage according to the value(s) in the table below.

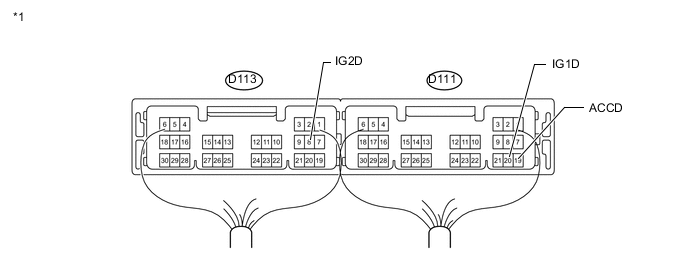

Text in Illustration *a Component with harness connected

(Power Management Control ECU)

- - Standard Voltage Tester Connection Switch Condition Specified Condition D111-20 (IG1D) - Body ground Engine switch off Below 1 V Engine switch on (ACC) Engine switch on (IG) ((Voltage at terminal AM21 or AM22) minus 2.0 V) or higher D113-8 (IG2D) - Body ground Engine switch off Below 1 V Engine switch on (ACC) Engine switch on (IG) ((Voltage at terminal AM21 or AM22) minus 2.0 V) or higher D111-19 (ACCD) - Body ground Engine switch off Below 1 V Engine switch on (ACC) ((Voltage at terminal AM21 or AM22) minus 2.0 V) or higher Engine switch on (IG) ((Voltage at terminal AM21 or AM22) minus 2.0 V) or higher

NG

REPLACE POWER MANAGEMENT CONTROL ECU Click here

OK

-

-

CHECK ENGINE SWITCH

-

Check that the power source mode changes to on (ACC) and on (IG) when operating the engine switch.

OK The power source mode changes to on (ACC) and on (IG) in response to the operation of the engine switch.

OK

END

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR (BATTERY - IG1 RELAY, IG2 RELAY AND ACC RELAY)

-

-

INSPECT ENGINE SWITCH

-

Text in Illustration *1 Component without harness connected

(Engine Switch)

Remove the engine switch.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Switch Condition Specified Condition 7 (SS1) - 5 (GND) Engine switch not pushed 10 kΩ or higher Engine switch pushed Below 1 Ω 2 (SS2) - 5 (GND) Engine switch not pushed 10 kΩ or higher Engine switch pushed Below 1 Ω Result Result Proceed to OK A NG for 1AD-FTV B NG for 2AD-FTV C NG for 2AD-FHV D

B

REPLACE ENGINE SWITCH Click here

C

REPLACE ENGINE SWITCH Click here

D

REPLACE ENGINE SWITCH Click here

A

-

-

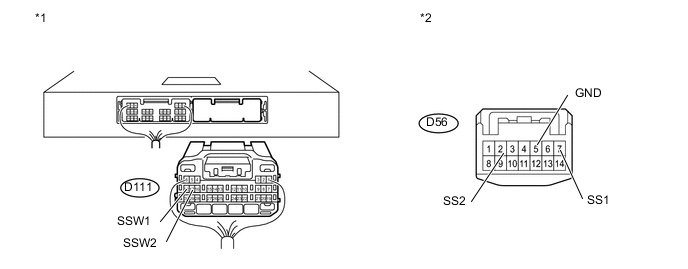

CHECK HARNESS AND CONNECTOR (POWER MANAGEMENT CONTROL ECU - ENGINE SWITCH)

-

Disconnect the D111 ECU connector.

Text in Illustration *1 Rear view of wire harness connector

(to Power Management Control ECU)

*2 Front view of wire harness connector

(to Engine Switch)

-

Disconnect the D56 engine switch connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition D111-17 (SSW2) - D56-2 (SS2) Always Below 1 Ω D111-18 (SSW1) - D56-7 (SS1) D111-17 (SSW2) - Body ground Always 10 kΩ or higher D111-18 (SSW1) - Body ground D56-5 (GND) - Body ground Always Below 1 Ω

OK

REPLACE POWER MANAGEMENT CONTROL ECU Click here

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

-

-

CHECK FOR DTC

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the intelligent tester on.

-

Enter the following menus: Body / Power Source / DTC.

-

Read the DTC.

-

Enter the following menus: Body / Entry & Start / DTC.

-

Read the DTC.

Result Result Proceed to None of the following DTCs are output:

B2785 Communication Malfunction between ECUs Connected by LIN

B2287 LIN Communication Master Malfunction

B2784 Antenna Coil Open/Short

A DTC B2287 is output but B2785 is not. B A DTC other than B2287 is output. C

A

GO TO ENTRY AND START SYSTEM (FOR ENTRY FUNCTION) (Room Oscillator does not Recognize Key) Click here

B

GO TO DTC (B2287) Click here

C

GO TO DTC CHART Click here

-