ENTRY AND START SYSTEM(for Start Function), Diagnostic DTC:B2282, B2283

| DTC Code | DTC Name |

|---|---|

| B2282 | Vehicle Speed Signal Malfunction |

| B2283 | Vehicle Speed Sensor Malfunction |

DESCRIPTION

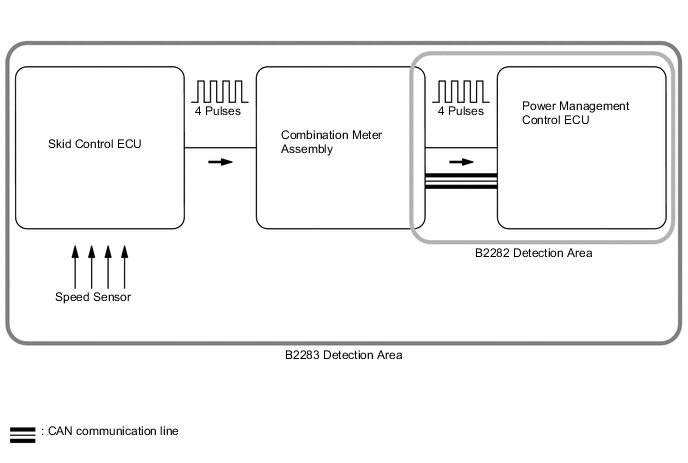

The power management control ECU and the combination meter are connected by a cable and the CAN communication lines. This DTC is stored when the cable information of the vehicle speed signal and CAN information of the vehicle speed signal are inconsistent.

Tech Tips

When the power management control ECU is replaced with a new one and the cable is connected to the negative (-) battery terminal, the power source mode is reset to on (IG). When the battery is removed and reinstalled, the power source mode that was selected when the battery was removed is restored.

| DTC Code | DTC Detection Condition | Trouble Area |

|---|---|---|

| B2282 | The cable information of the vehicle speed signal and CAN information of the vehicle speed signal are inconsistent. |

|

The skid control ECU converts signals from the speed sensor into 4-pulse signals and sends them to the combination meter. After these signals are converted into a more precise rectangular waveform by the waveform shaping circuit inside the combination meter, they are then transmitted to the power management control ECU. The power management control ECU determines the vehicle speed based on the frequencies of these pulse signals.

| DTC Code | DTC Detection Condition | Trouble Area |

|---|---|---|

| B2283 | Both conditions are met:

|

|

Tech Tips

-

A voltage of 12 V or 5 V is output from each ECU and then input to the combination meter. The signal is changed to a pulse signal at the transistor in the combination meter. Each ECU controls its respective system based on the pulse signal.

-

If a short occurs in an ECU, all systems related to the components in the diagram above will not operate normally.

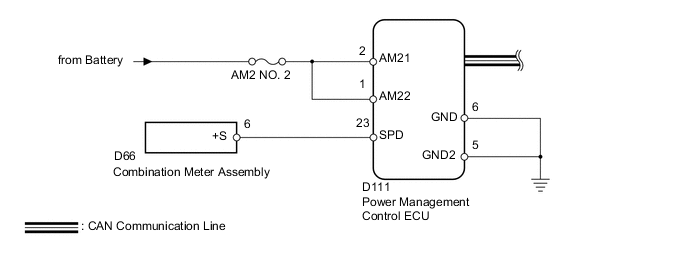

WIRING DIAGRAM

CAUTION / NOTICE / HINT

Note

-

When using the GTS with the engine switch off to troubleshoot: Connect the GTS to the vehicle, and turn a courtesy light switch on and off at 1.5 second intervals until communication between the GTS and vehicle begins.

-

Before performing the inspection, check that there are no problems related to the CAN communication system and LIN communication system.

-

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

-

CHECK HARNESS AND CONNECTOR (BATTERY - POWER MANAGEMENT CONTROL ECU)

-

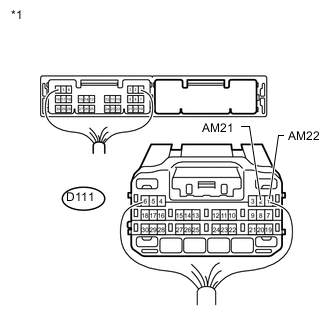

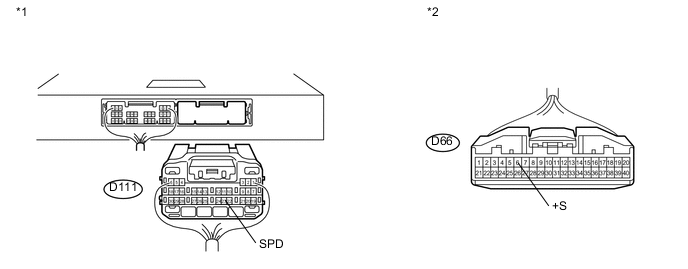

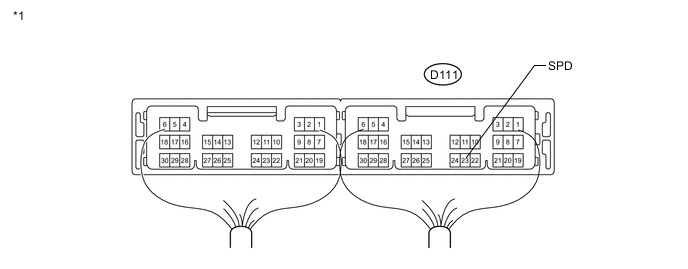

Text in Illustration *1 Rear view of wire harness connector

(to Power Management Control ECU)

Disconnect the D111 power management control ECU connector.

-

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Condition Specified Condition D111-2 (AM21) - Body ground Always 9.5 to 16 V D111-1 (AM22) - Body ground

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK HARNESS AND CONNECTOR (POWER MANAGEMENT CONTROL ECU - BODY GROUND)

-

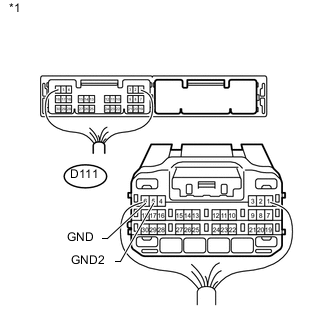

Disconnect the D111 power management control ECU connector.

-

Text in Illustration *1 Rear view of wire harness connector

(to Power Management Control ECU)

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition D111-6 (GND) - Body ground Always Below 1 Ω D111-5 (GND2) - Body ground

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK HARNESS AND CONNECTOR (POWER MANAGEMENT CONTROL ECU - COMBINATION METER)

-

Disconnect the D111 power management control ECU connector.

Text in Illustration *1 Rear view of wire harness connector

(to Power Management Control ECU)

*2 Front view of wire harness connector

(to Combination Meter Assembly)

-

Disconnect the D66 combination meter assembly connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition D111-23 (SPD) - D66-6 (+S) Always Below 1 Ω D111-23 (SPD) - Body ground Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

READ VALUE USING GTS (VEHICLE SPEED SIGNAL)

-

Connect the GTS to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the GTS on.

-

Enter the following menus: Body Electrical / Power Source Control / Data List.

-

According to the display on the GTS, read the Data List.

Power Source Control Tester Display Measurement Item/Range Normal Condition Diagnostic Note Vehicle Speed Signal Vehicle speed signal / Stop or Run Stop: Vehicle stopped

Run: Vehicle driven (5 km/h (3 mph) or higher)

- OK Stop (Vehicle stopped) or Run (Vehicle driven) appears on the screen according the vehicle speed.

OK

GO TO METER/GAUGE SYSTEM (HOW TO PROCEED WITH TROUBLESHOOTING) Click here

NG

-

-

CHECK POWER MANAGEMENT CONTROL ECU

-

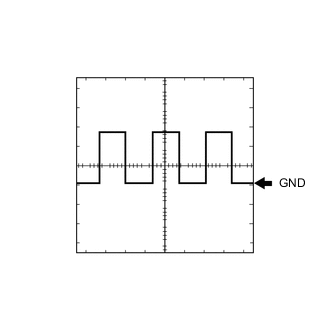

Using an oscilloscope, check the vehicle speed input signal waveform from the combination meter at the terminal of the power management control ECU.

Text in Illustration *1 Component with harness connected

(Power Management Control ECU)

- - -

Check the signal waveform according to the condition(s) in the table below.

Standard Frequency Tester Connection Condition Vehicle condition Specified Condition D111-23 (SPD) - Body ground 5 V/DIV., 10 ms./DIV. Engine switch on (IG), vehicle being driven at approx. 20 km/h (12 mph) Correct waveform as shown in illustration

OK

REPLACE POWER MANAGEMENT CONTROL ECU Click here

NG

GO TO METER/GAUGE SYSTEM (TERMINALS OF ECU) Click here

-