ENTRY AND START SYSTEM(for Entry Function) Room Oscillator does not Recognize Key

DESCRIPTION

If the room oscillator does not recognize the key, one of the following may be the cause: 1) communication between the indoor electrical key oscillator (for front floor) and electrical key transmitter cannot be performed; or 2) communication between the indoor electrical key oscillator (for rear floor) and electrical key transmitter cannot be performed; or 3) communication between the indoor electrical key oscillator (for inside luggage) and electrical key transmitter cannot be performed.

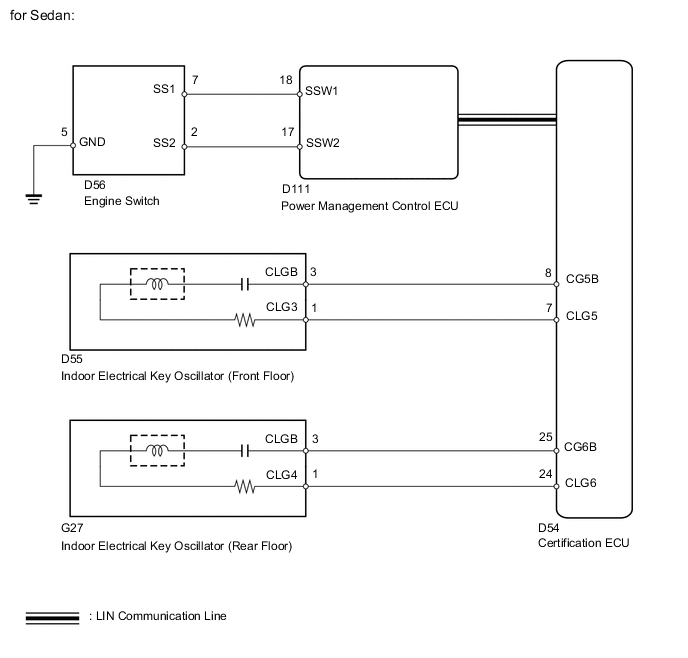

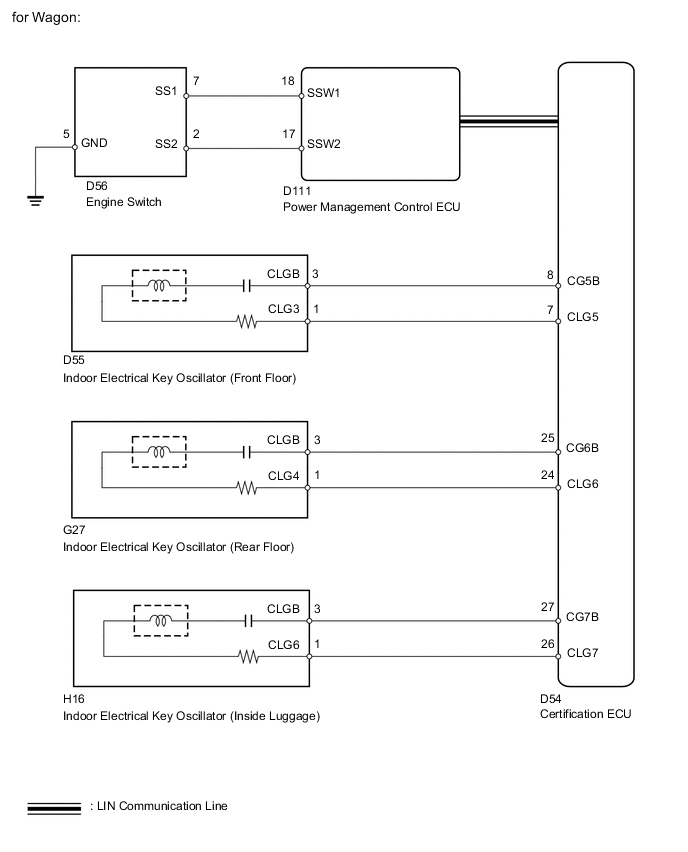

WIRING DIAGRAM

CAUTION / NOTICE / HINT

Note

-

Before performing the inspection, check that there are no problems related to the "CAN Communication System" and "LIN Communication System".

-

When using the intelligent tester with the engine switch off to troubleshoot: Connect the intelligent tester to the vehicle, and turn a courtesy light switch on and off at 1.5 second intervals until communication between the tester and vehicle begins.

PROCEDURE

-

CHECK ENTRY AND START SYSTEM (START FUNCTION)

-

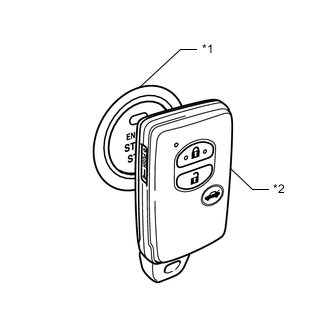

Text in Illustration *1 Engine Switch *2 Key Remove the battery of the electrical key transmitter Click here.

-

With the clutch pedal depressed (for Manual Transaxle) or brake pedal depressed (except Manual Transaxle), touch the TOYOTA mark of the key to the engine switch.

-

When operating the engine switch, check whether the power source mode changes.

OK Power source mode changes. Tech Tips

-

When the electrical key transmitter cannot be verified even though it is in the operating range of the start function, the engine start check can be performed by removing the transmitter battery from the electrical key transmitter and holding the transmitter against the engine switch.

-

When performing the check, if the power source mode changes, there is a problem with key certification inside the cabin.

-

NG

CHECK HARNESS AND CONNECTOR (POWER MANAGEMENT CONTROL ECU - ENGINE SWITCH) Click here

OK

-

-

CHECK WAVE ENVIRONMENT

-

for Wagon:

-

Install the battery to the electrical key transmitter Click here.

-

Bring the electrical key transmitter near the indoor electrical key oscillator (in center console) and perform an engine control system start check.

Note

If the key is brought within 0.2 m (0.656 ft.) of the center console, communication is not possible.

OK Engine starts. -

Bring the electrical key transmitter near the indoor electrical key oscillator (in rear seat cushion) and perform an engine control system start check.

Note

If the key is brought within 0.2 m (0.656 ft.) of the rear seat cushion, communication is not possible.

OK Engine starts. -

Bring the electrical key transmitter near the indoor electrical key oscillator (inside luggage area) and perform an engine control system start check.

Note

If the key is brought within 0.2 m (0.656 ft.) of the oscillator location inside the luggage compartment, communication is not possible.

-

-

for Sedan:

-

Install the battery to the electrical key transmitter Click here.

-

Bring the electrical key transmitter near the indoor electrical key oscillator (in center console) and perform an engine control system start check.

Note

If the key is brought within 0.2 m (0.656 ft.) of the center console, communication is not possible.

OK Engine starts. -

Bring the electrical key transmitter near the indoor electrical key oscillator (in rear seat cushion) and perform an engine control system start check.

Note

If the key is brought within 0.2 m (0.656 ft.) of the rear seat cushion, communication is not possible.

OK Engine starts. Tech Tips

-

When the electrical key transmitter is brought near the indoor electrical key oscillator, the possibility of wave interference decreases, and it can be determined if wave interference is causing the problem symptom.

-

If the inspection result is that the operation check is normal, the possibility of wave interference is high. Also, added vehicle components may cause wave interference, If installed, remove them and perform the operation check.

OK Engine starts. -

-

OK

AFFECTED BY WAVE INTERFERENCE

NG

-

-

KEY DIAGNOSTIC MODE

-

for Wagon:

-

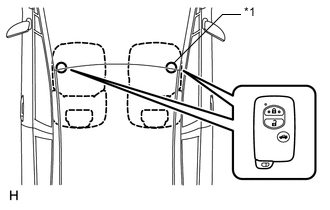

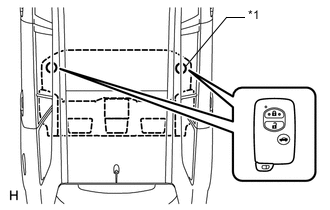

Text in Illustration *1 Inspection Point Diagnostic mode inspection (indoor electrical key oscillator (for front floor)).

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the intelligent tester on.

-

Enter the following menus: Body / Entry&Start / Key Communication Check / Overhead + Front Room.

-

When the electrical key transmitter is placed on the driver seat or front passenger seat cushion, check that the wireless door lock buzzer sounds.

-

-

Text in Illustration *1 Inspection Point Diagnostic mode inspection (indoor electrical key oscillator (for rear floor)).

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the intelligent tester on.

-

Enter the following menus: Body / Entry&Start / Key Communication Check / Overhead + Rear Room.

-

When the electrical key transmitter is placed on the rear seat cushion, check that the wireless door lock buzzer sounds.

-

-

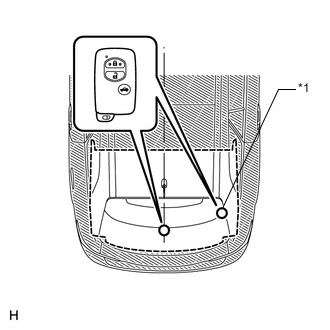

Text in Illustration *1 Inspection Point Diagnostic mode inspection (indoor electrical key oscillator (for inside luggage)).

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the intelligent tester on.

-

Enter the following menus: Body / Entry&Start / Key Communication Check / Overhead + Back Door (inside) Room.

-

When the electrical key transmitter is placed in the luggage area, check that the wireless door lock buzzer sounds.

-

-

-

for Sedan:

-

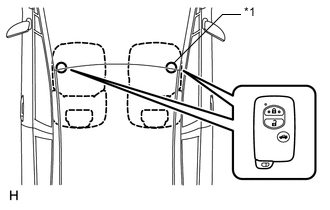

Text in Illustration *1 Inspection Point Diagnostic mode inspection (indoor electrical key oscillator (for front floor)).

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the intelligent tester on.

-

Enter the following menus: Body / Entry&Start / Key Communication Check / Overhead + Front Room.

-

When the electrical key transmitter is placed on the driver seat or front passenger seat cushion, check that the wireless door lock buzzer sounds.

-

-

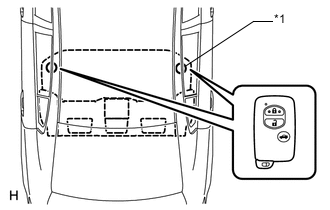

Text in Illustration *1 Inspection Point Diagnostic mode inspection (indoor electrical key oscillator (for rear floor)).

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the intelligent tester on.

-

Enter the following menus: Body / Entry&Start / Key Communication Check / Overhead + Rear Room.

-

When the electrical key transmitter is placed on the rear seat cushion, check that the wireless door lock buzzer sounds.

-

Tech Tips

-

If the buzzer sounds, it can be determined that the vehicle interior transmitters are operating normally.

-

It is possible to check which indoor electrical key oscillator (front, rear or luggage*) is operating by sounding the buzzer.

-

If the buzzer does not sound for any indoor electrical key oscillators, the certification ECU circuit may have a malfunction.

Result Result Proceed to Front operation check fails A Rear operation check fails B Luggage operation check fails* C Front, rear and luggage operation checks are normal D Front, rear and luggage operation checks fail E

-

*: for Wagon

-

B

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU - INDOOR ELECTRICAL KEY OSCILLATOR) Click here

C

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU - INDOOR ELECTRICAL KEY OSCILLATOR) Click here

D

INSPECT TRANSMITTER BATTERY (VOLTAGE) Click here

E

REPLACE CERTIFICATION ECU

A

-

-

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU - INDOOR ELECTRICAL KEY OSCILLATOR)

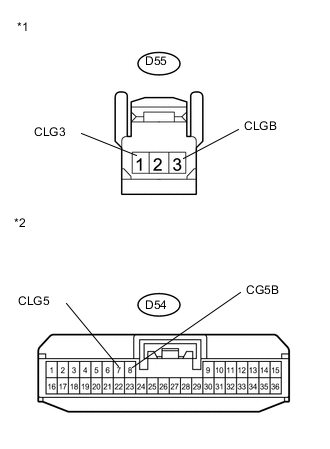

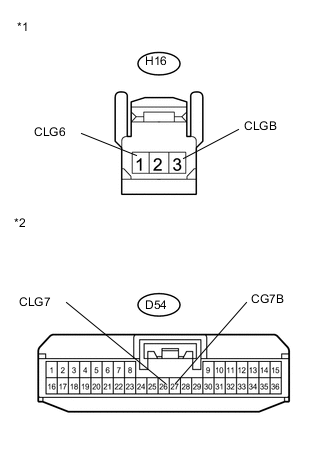

Text in Illustration *1 Front view of wire harness connector

(to Indoor Electrical Key Oscillator (for Front Floor))

*2 Front view of wire harness connector

(to Certification ECU)

-

Disconnect the D54 ECU connector.

-

Disconnect the D55 oscillator connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition D55-1 (CLG3) - D54-7 (CLG5) Always Below 1 Ω D55-3 (CLGB) - D54-8 (CG5B) Always Below 1 Ω D55-1 (CLG3) - Body ground Always 10 kΩ or higher D55-3 (CLGB) - Body ground Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK INDOOR ELECTRICAL KEY OSCILLATOR (FOR FRONT FLOOR)

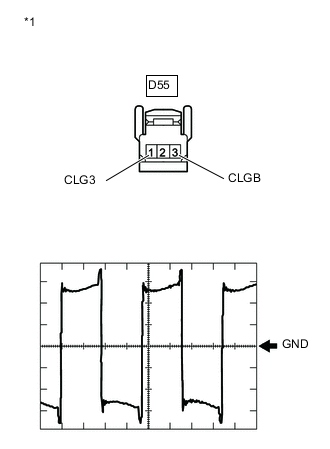

Text in Illustration *1 Front view of wire harness connector

(to Indoor Electrical Key Oscillator (for Front Floor))

-

Disconnect the D55 oscillator connector.

-

Measure the voltage according to the value(s) in the table below.

Waveform (Reference) Item Content Tester Connection D55-1 (CLG3) - D55-3 (CLGB) Tool Setting 2 V/DIV, 2 μsec./DIV. (Reference) Condition Engine switch on (IG) OK Waveform is output normally (Refer to illustration).

NG

REPLACE CERTIFICATION ECU

OK

-

-

REPLACE INDOOR ELECTRICAL KEY OSCILLATOR (FOR FRONT FLOOR)

-

Temporarily replace the indoor electrical key oscillator (for front floor) with a new or normally functioning one Click here.

NEXT

-

-

CHECK ENTRY AND START SYSTEM (FOR START FUNCTION)

-

Check that the engine switch indicator is illuminated in green, push the engine switch, and check that the engine starts.

OK Engine can be started.

OK

END (INDOOR ELECTRICAL KEY OSCILLATOR IS DEFECTIVE)

NG

REPLACE CERTIFICATION ECU

-

-

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU - INDOOR ELECTRICAL KEY OSCILLATOR)

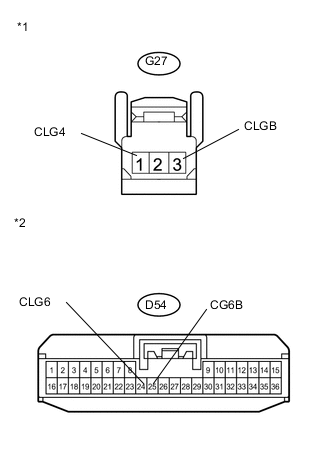

Text in Illustration *1 Front view of wire harness connector

(to Indoor Electrical Key Oscillator (for Rear Floor))

*2 Front view of wire harness connector

(to Certification ECU)

-

Disconnect the D54 ECU connector.

-

Disconnect the G27 oscillator connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition G27-1 (CLG4) - D54-24 (CLG6) Always Below 1 Ω G27-3 (CLGB) - D54-25 (CG6B) Always Below 1 Ω G27-1 (CLG4) - Body ground Always 10 kΩ or higher G27-3 (CLGB) - Body ground Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK INDOOR ELECTRICAL KEY OSCILLATOR (FOR REAR FLOOR)

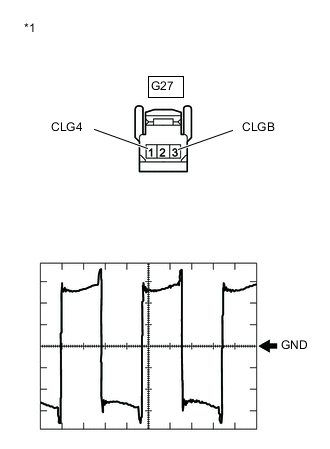

Text in Illustration *1 Front view of wire harness connector

(to Indoor Electrical Key Oscillator (for Rear Floor))

-

Disconnect the G27 oscillator connector.

-

Measure the voltage according to the value(s) in the table below.

Waveform (Reference) Item Content Tester Connection G27-1 (CLG4) - G27-3 (CLGB) Tool Setting 2 V/DIV, 2 μsec./DIV. (Reference) Condition Engine switch on (IG) OK Waveform is output normally (Refer to illustration).

NG

REPLACE CERTIFICATION ECU

OK

-

-

REPLACE INDOOR ELECTRICAL KEY OSCILLATOR (FOR REAR FLOOR)

-

Temporarily replace the indoor electrical key oscillator (for rear floor) with a new or normally functioning one Click here.

NEXT

-

-

CHECK ENTRY AND START SYSTEM (FOR START FUNCTION)

-

Check that the engine switch indicator is illuminated in green, push the engine switch, and check that the engine starts.

OK Engine can be started.

OK

END (INDOOR ELECTRICAL KEY OSCILLATOR IS DEFECTIVE)

NG

REPLACE CERTIFICATION ECU

-

-

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU - INDOOR ELECTRICAL KEY OSCILLATOR)

Text in Illustration *1 Front view of wire harness connector

(to Indoor Electrical Key Oscillator (for Inside Luggage))

*2 Front view of wire harness connector

(to Certification ECU)

-

Disconnect the D54 ECU connector.

-

Disconnect the H16 oscillator connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition H16-1 (CLG6) - D54-26 (CLG7) Always Below 1 Ω H16-3 (CLGB) - D54-27 (CG7B) Always Below 1 Ω H16-1 (CLG6) - Body ground Always 10 kΩ or higher H16-3 (CLGB) - Body ground Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK INDOOR ELECTRICAL KEY OSCILLATOR (FOR INSIDE LUGGAGE)

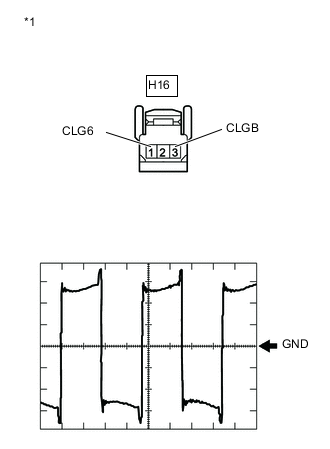

Text in Illustration *1 Front view of wire harness connector

(to Indoor Electrical Key Oscillator (for Inside Luggage))

-

Disconnect the H16 oscillator connector.

-

Measure the voltage according to the value(s) in the table below.

Waveform (Reference) Item Content Tester Connection H16-1 (CLG6) - H16-3 (CLGB) Tool Setting 2 V/DIV, 2 μsec./DIV. (Reference) Condition Engine switch on (IG) OK Waveform is output normally (Refer to illustration).

NG

REPLACE CERTIFICATION ECU

OK

-

-

REPLACE INDOOR ELECTRICAL KEY OSCILLATOR (FOR INSIDE LUGGAGE)

-

Temporarily replace the indoor electrical key oscillator (for inside luggage) with a new or normally functioning one Click here.

NEXT

-

-

CHECK ENTRY AND START SYSTEM (FOR START FUNCTION)

-

Check that the engine switch indicator is illuminated in green, push the engine switch, and check that the engine starts.

OK Engine can be started.

OK

END (INDOOR ELECTRICAL KEY OSCILLATOR IS DEFECTIVE)

NG

REPLACE CERTIFICATION ECU

-

-

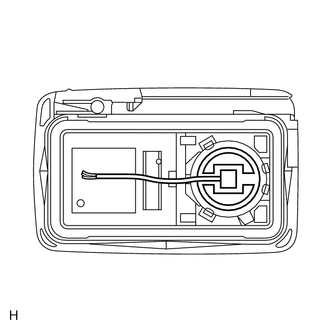

INSPECT TRANSMITTER BATTERY (VOLTAGE)

-

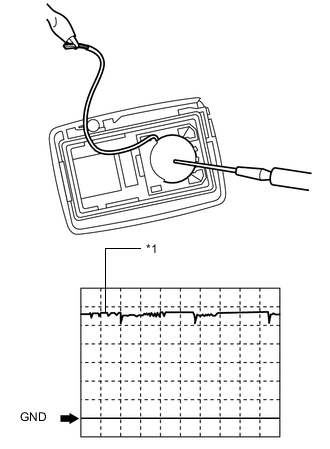

Remove the battery from the electrical key transmitter that does not operate. Attach a lead wire (0.6 mm (0.0236 in.) or less in diameter including wire sheath) with tape or equivalent to the negative terminal Click here.

Note

Do not wrap the lead wire around a terminal, wedge it between terminals, or solder it. A terminal may be deformed or damaged, and the battery will not be able to be installed correctly.

-

Carefully pull the lead wire out from the position shown in the illustration and install the previously removed transmitter battery.

-

Text in Illustration *1 Measurement Position Using an oscilloscope, check the transmitter battery voltage waveform.

Tech Tips

When measuring the battery voltage, while operating the lock switch of a door handle, bring the electrical key transmitter within the entry operating range to perform the measurement. For the entry operating range, refer to System Description Click here.

OK Tester Connection Tool Setting Condition Specified Condition Battery positive (+) - Battery negative (-) 0.5 V/DIV., 100 ms/DIV. Engine switch off, all doors closed and lock switch pushed 2.5 to 3.2 V (Refer to the waveform)

NG

REPLACE TRANSMITTER BATTERY Click here

OK

-

-

CHECK ELECTRICAL KEY TRANSMITTER

-

Check if there is another registered transmitter available.

Result Result Proceed to Another registered transmitter is not available A Another registered transmitter is available B

B

CHECK ENTRY AND START SYSTEM Click here

A

-

-

REPLACE ELECTRICAL KEY TRANSMITTER

-

Replace the electrical key transmitter.

-

Register the electrical key transmitter.

NEXT

-

-

CHECK ENTRY AND START SYSTEM

-

Check that the engine switch indicator is illuminated in green, push the engine switch, and check that the engine starts.

OK Engine can be started.

OK

END (ELECTRICAL KEY TRANSMITTER IS DEFECTIVE)

NG

REPLACE CERTIFICATION ECU

-

-

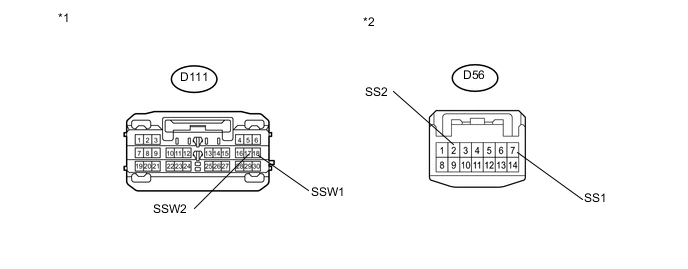

CHECK HARNESS AND CONNECTOR (POWER MANAGEMENT CONTROL ECU - ENGINE SWITCH)

Text in Illustration *1 Front view of wire harness connector

(to Power Management Control ECU)

*2 Front view of wire harness connector

(to Engine Switch)

-

Disconnect the D111 ECU connector.

-

Disconnect the D56 switch connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition D56-7 (SS1) - D111-18 (SSW1) Always Below 1 Ω D56-2 (SS2) - D111-17 (SSW2) Always Below 1 Ω D56-7 (SS1) - Body ground Always 10 kΩ or higher D56-2 (SS2) - Body ground Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

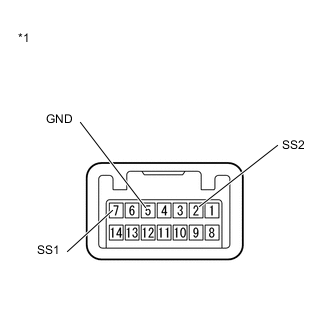

INSPECT ENGINE SWITCH

-

Text in Illustration *1 Component without harness connected

(Engine Switch)

Remove the engine switch.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Switch Condition Specified Condition 7 (SS1) - 5 (GND) Engine switch pushed Below 1 Ω Engine switch not pushed 10 kΩ or higher 2 (SS2) - 5 (GND) Engine switch pushed Below 1 Ω Engine switch not pushed 10 kΩ or higher 5 (GND) - Body ground Always Below 1 Ω Result Result Proceed to OK A NG (for 1WW) B NG (for 2WW) C

A

REPLACE POWER MANAGEMENT CONTROL ECU Click here

B

REPLACE ENGINE SWITCH Click here

C

REPLACE ENGINE SWITCH Click here

-