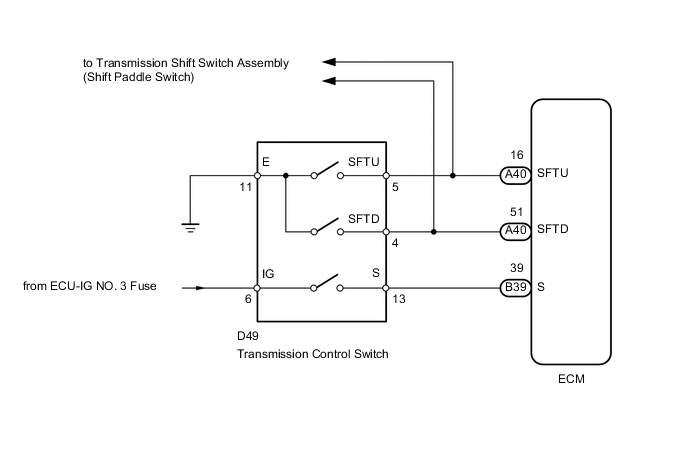

CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM Transmission Control Switch Circuit

DESCRIPTION

After moving the shift lever to M, it is possible to switch the shift range between "1" (M1 gear) and "7" (M7 gear) using the transmission control switch.

Moving the shift lever to "+" once raises the shift range by one, and moving the shift lever to "-" lowers the shift range by one.

WIRING DIAGRAM

PROCEDURE

-

INSPECT TRANSMISSION CONTROL SWITCH

-

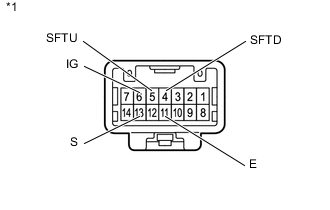

Text in Illustration *1 Component without harness connected

(Transmission Control Switch)

Disconnect the transmission control switch connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition 6 (IG) - 13 (S) Shift lever in M, "+" or "-" Below 1 Ω 5 (SFTU) - 11 (E) Shift lever held in "+" (Up-shift) Below 1 Ω 4 (SFTD) - 11 (E) Shift lever held in "-" (Down-shift) Below 1 Ω 6 (IG) - 13 (S) Shift lever not in M, "+" or "-" 10 kΩ or higher 5 (SFTU) - 11 (E) Shift lever in M 10 kΩ or higher 4 (SFTD) - 11 (E) Shift lever in M 10 kΩ or higher

NG

REPLACE TRANSMISSION CONTROL SWITCH (SHIFT LOCK CONTROL UNIT ASSEMBLY) Click here

OK

-

-

CHECK HARNESS AND CONNECTOR (TRANSMISSION CONTROL SWITCH - BATTERY AND BODY GROUND)

-

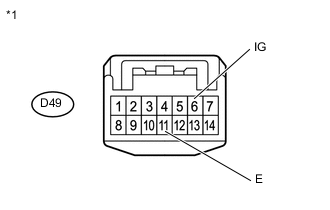

Text in Illustration *1 Front view of wire harness connector

(to Transmission Control Switch)

Disconnect the transmission control switch connector.

-

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Switch Condition Specified Condition D49-6 (IG) - Body ground Ignition switch ON 11 to 14 V D49-6 (IG) - Body ground Ignition switch off Below 1 V -

Turn the ignition switch off.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition D49-11 (E) - Body ground Always Below 1 Ω

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK HARNESS AND CONNECTOR (TRANSMISSION CONTROL SWITCH - ECM)

-

Text in Illustration *1 Front view of wire harness connector

(to ECM)

Disconnect the ECM connectors.

-

Turn the ignition switch to ON.

-

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Condition Specified Condition B39-39 (S) - Body ground

-

Ignition switch ON

-

Shift lever in M, "+" or "-"

11 to 14 V B39-39 (S) - Body ground

-

Ignition switch ON

-

Shift lever not in M, "+" or "-"

Below 1 V -

-

Turn the ignition switch off.

-

Disconnect the spiral cable sub-assembly connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A40-16 (SFTU) - Body ground Shift lever held in "+" (Up-shift) Below 1 Ω A40-51 (SFTD) - Body ground Shift lever held in "-" (Down-shift) Below 1 Ω A40-16 (SFTU) - Body ground Shift lever in M 10 kΩ or higher A40-51 (SFTD) - Body ground Shift lever in M 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

REPLACE ECM

-

Replace the ECM Click here.

NEXT

-

-

PERFORM INITIALIZATION

Note

-

Performing reset memory will clear the learned values of both the yaw rate sensor (deceleration sensor 0 point calibration) and CVT oil pressure (CVT oil pressure calibration). Make sure to perform reset memory, yaw rate sensor 0 point calibration and CVT oil pressure calibration when replacing any of the parts shown in the following table:

Replaced Part

-

Continuously variable transaxle assembly

-

ECM

-

Oil pressure sensor

-

Yaw rate sensor

-

-

After performing reset memory, always perform yaw rate sensor (deceleration sensor 0 point) calibration first, and then CVT oil pressure calibration.

-

Always perform 0 point calibration with the vehicle on level ground (Inclination: 0 +/-0.25°).

-

Do not shake or vibrate the vehicle during 0 point calibration.

-

Using the intelligent tester, perform reset memory, deceleration sensor 0 point calibration and CVT oil pressure calibration Click here.

-

Check that no DTC is stored.

NEXT

END

-