AUTOMATIC TRANSAXLE UNIT INSPECTION

-

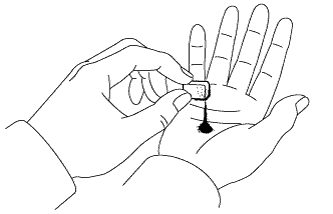

INSPECT TRANSMISSION OIL CLEANER MAGNET

-

Use the removed transmission oil cleaner magnets to collect any steel chips. Examine the chips and particles in the automatic transaxle oil pan sub-assembly and on the transmission oil cleaner magnets to determine what type of wear has occurred in the automatic transaxle assembly:

Result Steel (magnetic) Bearing, gear and plate wear Brass (non-magnetic) Bushing wear

-

-

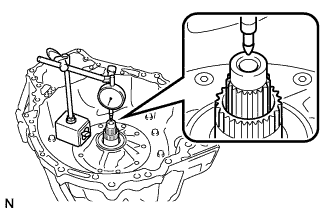

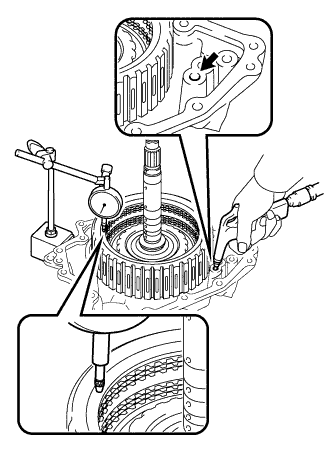

INSPECT INPUT SHAFT SUB-ASSEMBLY

-

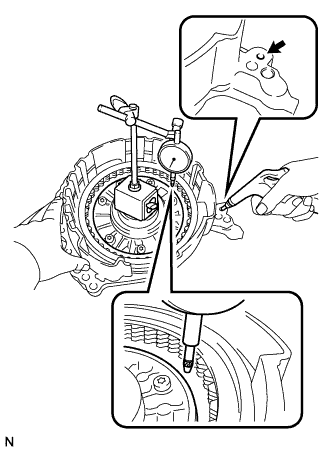

Using a dial indicator, measure the input shaft sub-assembly end play.

End play 0.020 to 1.242 mm (0.000787 to 0.0489 in.)

-

-

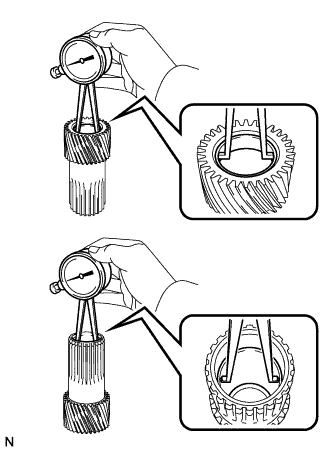

INSPECT PLANETARY SUN GEAR SUB-ASSEMBLY

-

Using a dial indicator, measure the inside diameter of the bushings of the planetary sun gear sub-assembly.

Standard inside diameter 25.525 to 25.546 mm (1.00492 to 1.00575 in.) Maximum inside diameter 25.546 mm (1.00575 in.) If the inside diameter is greater than the maximum, replace the planetary sun gear sub-assembly.

-

-

INSPECT NO. 3 BRAKE DISC

-

Check if the contact surfaces of the No. 3 brake discs, No. 3 brake plates and No. 3 brake flanges are worn or burnt.

Note

-

If the lining of any No. 3 brake disc is peeled off or discolored, or even if part of the groove is damaged, replace all No. 3 brake discs.

-

Before assembling new No. 3 brake discs, soak them in ATF for at least 15 minutes.

If necessary, replace them.

-

-

-

INSPECT UNDERDRIVE PLANETARY GEAR ASSEMBLY

-

Using a feeler gauge, measure the clearance between the underdrive planetary gear assembly and the pinion gear at 4 points.

Standard clearance 0.18 to 0.54 mm (0.00709 to 0.0213 in.) If the clearance is greater than the standard clearance, replace the underdrive planetary gear assembly.

-

-

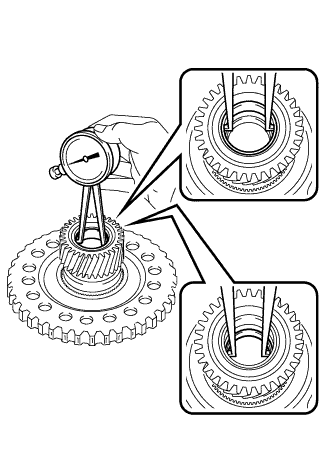

INSPECT REAR PLANETARY SUN GEAR ASSEMBLY

-

Using a dial indicator, measure the inside diameter of the bushing of the rear planetary sun gear assembly.

Standard inside diameter 25.580 to 25.601 mm (1.00708 to 1.00791 in.) Maximum inside diameter 25.601 mm (1.00791 in.) If the inside diameter is greater than the maximum, replace the rear planetary sun gear assembly.

-

-

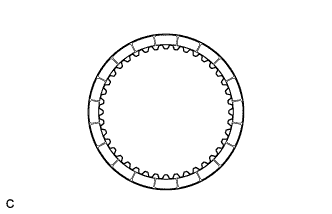

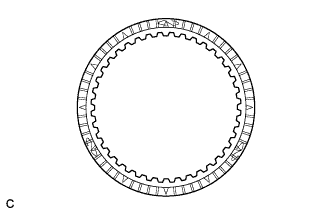

INSPECT NO. 1 BRAKE DISC

-

Check if the contact surfaces of the No. 1 brake discs, No. 1 brake plates and No. 1 brake flange are worn or burnt.

Note

-

If the lining of any No. 1 brake disc is peeled off or discolored, or even if part of the groove is damaged, replace all No. 1 brake discs.

-

Before assembling new No. 1 brake discs, soak them in ATF for at least 15 minutes.

If necessary, replace them.

-

-

-

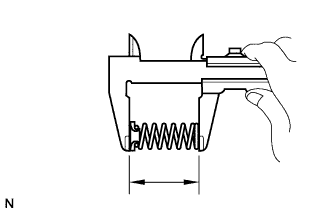

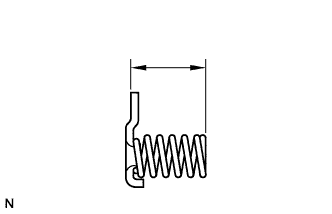

INSPECT 2ND BRAKE PISTON RETURN SPRING SUB-ASSEMBLY

-

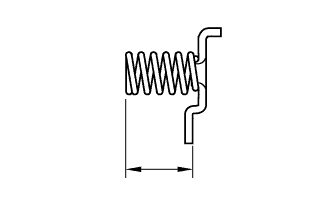

Using a vernier caliper, measure the free length of the 3 2nd brake piston return spring sub-assemblies including the spring seats.

Standard free length 23.26 mm (0.916 in.) If the free length is shorter than the standard free length, replace the 2nd brake piston return spring sub-assembly.

-

-

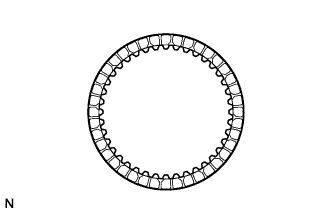

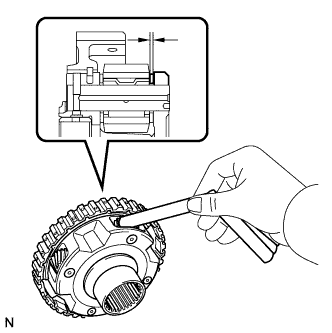

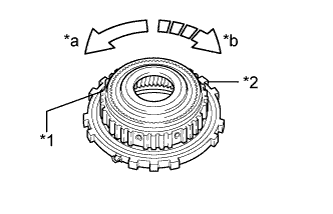

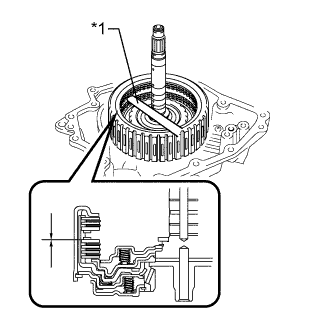

INSPECT ONE-WAY CLUTCH ASSEMBLY

-

Text in Illustration *1 Planetary Ring Gear *2 One-way Clutch Assembly *a Free *b Lock Temporarily install the one-way clutch assembly to the planetary ring gear.

-

Make sure that the one-way clutch assembly turns freely counterclockwise and locks when turned clockwise.

If the one-way clutch assembly does not operate normally, replace it.

-

-

INSPECT NO. 2 BRAKE DISC

-

Check if the contact surfaces of the No. 2 brake discs, No. 2 brake plates and No. 2 brake flange are worn or burnt.

Note

-

If the lining of any No. 2 brake disc is peeled off or discolored, or even if part of the groove is damaged, replace all No. 2 brake discs.

-

Before assembling new No. 2 brake discs, soak them in ATF for at least 15 minutes.

If necessary, replace them.

-

-

-

INSPECT 1ST AND REVERSE BRAKE RETURN SPRING SUB-ASSEMBLY

-

Using a vernier caliper, measure the free length of the 1st and reverse brake return spring sub-assembly together with the spring seat.

Standard free length 15.79 mm (0.622 in.) If the free length is shorter than the standard free length, replace the 1st and reverse brake return spring sub-assembly.

-

-

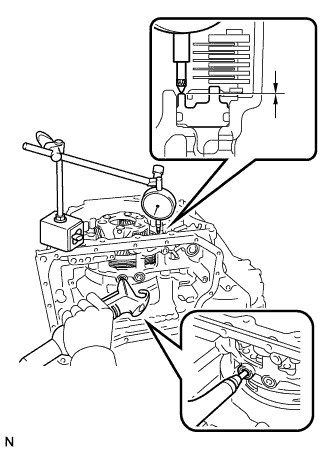

INSPECT CLEARANCE OF NO. 2 BRAKE PISTON

-

Using a dial indicator, measure the clearance of the No. 2 brake piston while applying compressed air (200 kPa, 2.0 kgf/cm2, 29 psi).

Standard clearance 0.884 to 1.196 mm (0.0348 to 0.0471 in.) Tech Tips

Measure the clearance at 3 points where the piston diameter is approximately 140 mm (5.51 in.) and calculate the average.

If the clearance is not as specified, select an appropriate No. 2 brake flange so that the clearance will be within the specified range.

Tech Tips

There are 5 No. 2 brake flanges of different thicknesses.

No. 2 Brake Flange Thickness: mm (in.) Mark Thickness 40 4.0 (0.157) 41 4.1 (0.161) 42 4.2 (0.165) 43 4.3 (0.169) 44 4.4 (0.173)

-

-

INSPECT CLEARANCE OF NO. 1 BRAKE PISTON

-

Using a dial indicator, measure the clearance of the No. 1 brake piston while applying compressed air (200 kPa, 2.0 kgf/cm2, 29 psi).

Standard clearance 0.601 to 0.819 mm (0.0237 to 0.0322 in.) Tech Tips

Measure the clearance at 3 points where the No. 1 brake piston diameter is approximately 140 mm (5.51 in.) and calculate the average.

If the clearance is not as specified, select an appropriate No. 1 brake flange so that the clearance will be within the specified range.

Tech Tips

There are 6 No. 1 brake flanges of different thicknesses.

No. 1 Brake Flange Thickness: mm (in.) Mark Thickness 30 3.0 (0.118) 31 3.1 (0.122) 32 3.2 (0.126) 33 3.3 (0.130) 34 3.4 (0.134) 35 3.5 (0.138)

-

-

INSPECT NO. 3 BRAKE PISTON RETURN SPRING SUB-ASSEMBLY

-

Using a vernier caliper, measure the free length of the No. 3 brake piston return spring sub-assembly together with the spring seat.

Standard free length 9.15 mm (0.360 in.) If the free length is shorter than the standard free length, replace the No. 3 brake piston return spring sub-assembly.

-

-

INSPECT CLEARANCE OF NO. 3 BRAKE PISTON

-

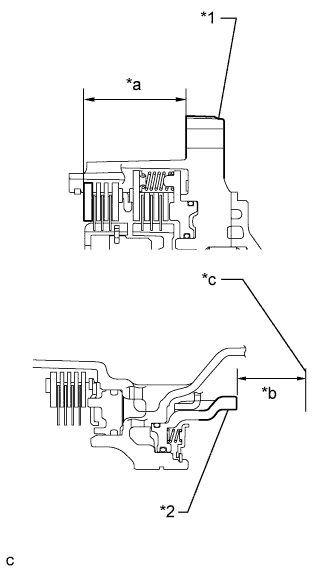

Text in Illustration *1 Front Oil Pump Assembly *2 No. 3 Brake Piston *a Dimension A *b Dimension B *c Contact Surface of Front Oil Pump Assembly Using a vernier caliper and a straightedge, measure the distance shown in the illustration (Dimension A) while a load of 500 N (51 kgf, 112.4 lbf) is being applied to the flange.

Tech Tips

Measure dimension A at 3 points where the flange diameter is approximately 166 mm (6.54 in.) and calculate the average.

-

Using a vernier caliper and a straightedge, measure the distance shown in the illustration (Dimension B).

Tech Tips

Measure dimension B at 3 points where the No. 3 brake diameter is approximately 166 mm (6.54 in.) and calculate the average.

-

Calculate the clearance value using the following formula:

Clearance = Dimension B - Dimension A - Flange Thickness

Standard clearance 0.599 to 0.799 mm (0.0236 to 0.0315 in.) If the clearance is not as specified, select an appropriate No. 3 brake flange so that the clearance will be within the specified range.

Tech Tips

There are 6 No. 3 brake flanges of different thicknesses.

No. 3 Brake Flange Thickness: mm (in.) Mark Thickness 38 3.80 (0.150) 39 3.90 (0.154) 40 4.00 (0.157) 41 4.10 (0.161) 42 4.20 (0.165) 43 4.30 (0.169)

-

-

INSPECT CLEARANCE OF NO. 1 CLUTCH DISC

-

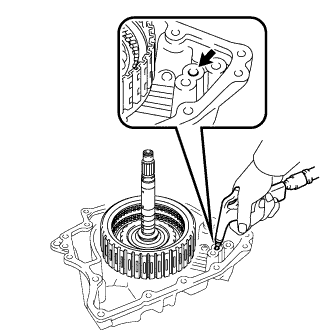

Install the direct multiple disc clutch assembly onto the rear transaxle cover sub-assembly.

-

Check that the piston moves when compressed air (200 kPa, 2.0 kgf/cm2, 29 psi) is applied to the oil hole.

-

Text in Illustration *1 Feeler Gauge Using a feeler gauge, measure the No. 1 clutch pack clearance.

Tech Tips

Measure the clearance at 3 points where the flange diameter is approximately 152 mm (5.98 in.) and calculate the average.

Pack clearance 0.601 to 0.819 mm (0.0237 to 0.0322 in.) If the pack clearance is not as specified, replace the direct multiple disc clutch assembly.

-

-

INSPECT CLEARANCE OF NO. 2 CLUTCH DISC

-

Install the direct multiple disc clutch assembly onto the rear transaxle cover sub-assembly.

-

Using a dial indicator, measure the No. 2 clutch pack clearance while applying and releasing compressed air (200 kPa, 2.0 kgf/cm2, 29 psi).

Tech Tips

Measure the clearance at 3 points where the diameter of the No. 2 direct multiple clutch piston is approximately 152 mm (5.98 in.) and calculate the average.

Pack clearance 0.394 to 0.605 mm (0.0155 to 0.0238 in.) If the pack clearance is not as specified, replace the direct multiple disc clutch assembly.

-