IGNITION SYSTEM ON-VEHICLE INSPECTION

-

PERFORM SPARK TEST

-

Check for DTCs Click here.

Note

If any DTC is output, perform the troubleshooting procedures for that DTC.

-

Check if sparks occur.

-

Remove the 6 spark plugs Click here.

-

Install the spark plug to the ignition coil and connect the ignition coil connector.

-

Remove the engine room relay block cover.

-

Remove the circuit opening relay (C/OPN) from the engine room relay block.

-

Ground the spark plug.

-

Visually check that sparks occur while the engine is being cranked.

Note

-

Be sure to ground the spark plug when checking.

-

Replace the ignition coil if it receives an impact.

-

Do not crank the engine for more than 2 seconds.

-

-

-

Check that the wire harness side connector of the ignition coil with igniter is securely connected.

Result Result Proceed to NG Connect securely OK Go to next step -

Perform a spark test on each ignition coil with igniter.

-

If there is a cylinder where sparks do not occur, replace its ignition coil with the ignition coil of a cylinder where sparks occur normally.

-

Crank the engine and visually check that sparks occur at the cylinder with the normally operating ignition coil.

Result Result Proceed to OK Replace ignition coil with igniter NG Go to next step

-

-

Inspect the spark plug.

-

Replace the spark plug with a normal one.

-

Perform spark test again.

Result Result Proceed to OK Replace spark plug NG Go to next step

-

-

Check power supply to ignition coil with igniter.

-

Turn the ignition switch to ON.

-

Check that there is battery voltage at the ignition coil positive (+) terminal.

Result Result Proceed to NG Check wiring between ignition switch and ignition coil with igniter OK Go to next step

-

-

Check the VVT sensor for intake side Click here and VVT sensor for exhaust side Click here.

-

Check the crankshaft position sensor Click here.

-

Install the 6 spark plugs Click here.

-

Install the circuit opening relay.

-

Install the engine room relay block cover.

-

-

INSPECT SPARK PLUG

-

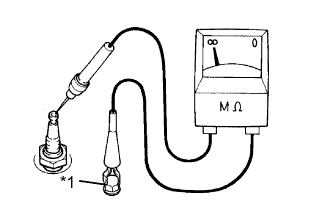

Text in Illustration *1 Body Ground Check the electrode.

-

Using a megohmmeter, measure the insulation resistance.

Standard Insulation Resistance Tester Connection Condition Specified Condition Spark plug (terminal part) - Body ground Always 10 MΩ or higher If a megohmmeter is not available, perform the following simple inspection.

-

-

Alternative inspection method:

-

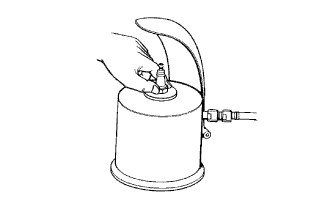

Quickly accelerate the engine to 4000 rpm 5 times.

-

Remove the spark plug.

-

Visually check the spark plug.

If the electrode is dry, the spark plug is functioning properly. If the electrode is damp, proceed to the next step.

-

-

Check the spark plug for any damage on its threads and insulator.

If there is damage, replace the spark plug. If not, reinstall the spark plug.

Recommended Spark Plug Manufacturer Product DENSO made SK16HR11 -

Clean the spark plugs.

-

Check the spark plug electrode gap.

Maximum electrode gap for used spark plug 1.3 mm (0.0512 in.) If the gap is more than the maximum, replace the spark plug.

Electrode gap for new spark plug 1.0 to 1.1 mm (0.0394 to 0.0433 in.)

-