GENERATOR INSTALLATION

-

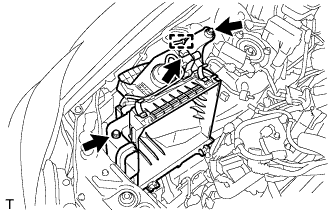

INSTALL GENERATOR

-

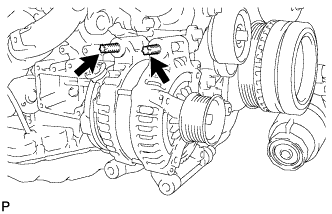

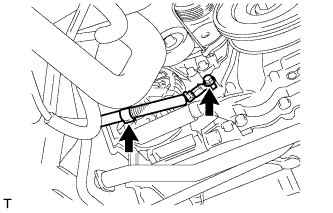

Using an E8 "TORX" socket wrench, set the generator with the 2 stud bolts.

- Torque:

- 10 N*m { 102 kgf*cm, 7 ft.*lbf }

-

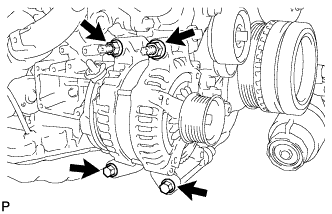

Install the generator with the 2 bolts and 2 nuts.

- Torque:

- 43 N*m { 438 kgf*cm, 32 ft.*lbf }

-

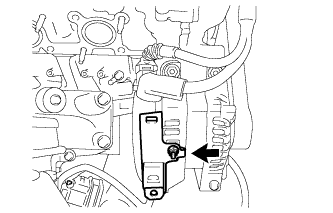

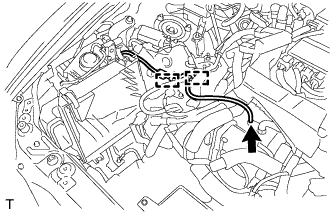

Install the wire harness bracket with the nut.

- Torque:

- 6.0 N*m { 61 kgf*cm, 53 in.*lbf }

-

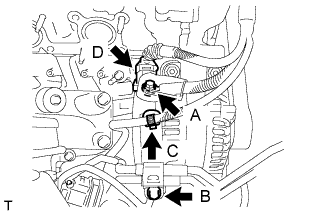

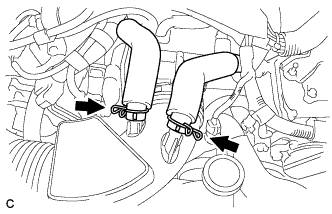

Connect the harness to the +B terminal with nut A.

- Torque:

- 12 N*m { 122 kgf*cm, 9 ft.*lbf }

-

Install the oil cooler tube with bolt B.

- Torque:

- 14 N*m { 140 kgf*cm, 10 ft.*lbf }

-

Connect wire harness clamp C.

-

Connect generator connector D.

-

-

INSTALL FRONT STABILIZER BAR

-

Install the front stabilizer bar Click here.

-

-

INSTALL WIRE HARNESS

-

Connect the wire harness with the bolt and clamp.

- Torque:

- 21 N*m { 214 kgf*cm, 15 ft.*lbf }

-

-

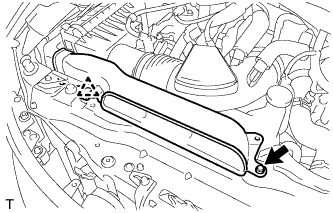

INSTALL V-RIBBED BELT

-

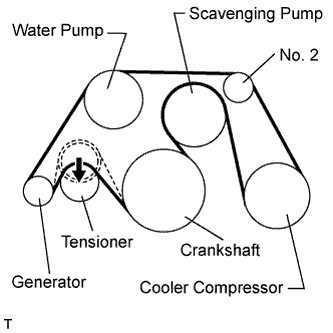

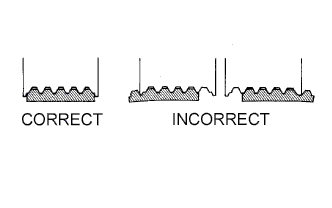

Install the V-ribbed belt as shown in the illustration.

-

Rotate the V-ribbed belt tensioner pulley counterclockwise, and then remove the bar.

Note

Check that the drive belt is properly set to each pulley.

-

Check that the belt is properly positioned on each pulley.

-

Start the engine and check that the belt turns smoothly and no abnormal noise occurs.

-

-

INSTALL RADIATOR RESERVE TANK ASSEMBLY

-

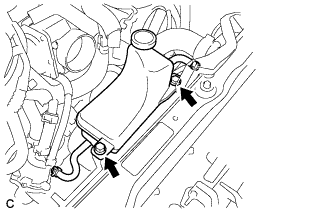

Install the radiator reserve tank assembly with the 2 bolts.

- Torque:

- 5.0 N*m { 51 kgf*cm, 44 in.*lbf }

-

-

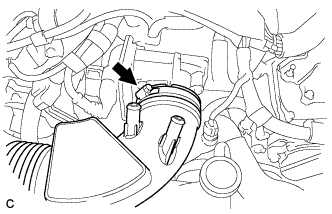

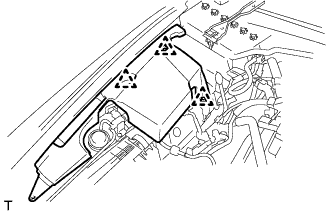

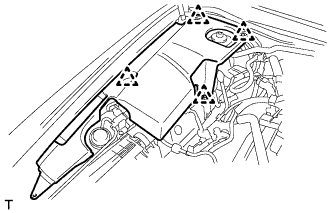

INSTALL AIR CLEANER CASE SUB-ASSEMBLY

-

Install the air cleaner case sub-assembly with the 2 bolts.

- Torque:

- 5.0 N*m { 51 kgf*cm, 44 in.*lbf }

-

Connect the vacuum switching valve connector and clamp.

-

Connect the vacuum hose and 2 clamps.

-

-

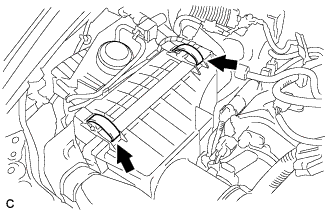

INSTALL AIR CLEANER CAP SUB-ASSEMBLY

-

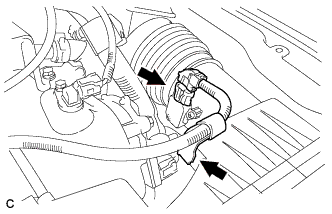

Install the air cleaner cap sub-assembly with air cleaner hose and lock the 2 clamps.

Tech Tips

Tightening torque for the hose clamp located between the air cleaner cap sub-assembly and air cleaner hose assembly is as follows.

- Torque:

- 4.0 N*m { 41 kgf*cm, 35 in.*lbf }

-

Connect the air cleaner hose to the throttle body with the hose clamp.

- Torque:

- 4.0 N*m { 41 kgf*cm, 35 in.*lbf }

-

Connect the 2 ventilation hoses with the 2 hose clamps.

-

Connect the mass air flow meter connector and wire harness clamp.

-

-

INSTALL NO. 1 AIR CLEANER INLET

-

Install the No. 1 air cleaner inlet with the bolt and clip.

- Torque:

- 5.0 N*m { 51 kgf*cm, 44 in.*lbf }

-

-

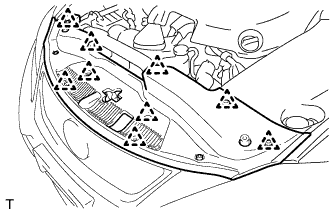

INSTALL REAR ENGINE UNDER COVER LH

-

INSTALL REAR ENGINE UNDER COVER RH

-

INSTALL ENGINE UNDER COVER

-

INSTALL ENGINE ROOM SIDE COVER RH (for LHD)

-

Install the engine room side cover RH with the 3 clips.

-

-

INSTALL ENGINE ROOM SIDE COVER RH (for RHD)

-

Install the engine room side cover RH with the 4 clips.

-

-

INSTALL COOL AIR INTAKE DUCT SEAL

-

Install the cool air intake duct seal with the 9 clips.

-

-

REMOVE FRONT WHEELS

-

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

Note

When disconnecting the cable, some systems need to be initialized after the cable is reconnected Click here.