SFI SYSTEM (w/o Electronic Throttle Control System), Diagnostic DTC:P0138

DESCRIPTION

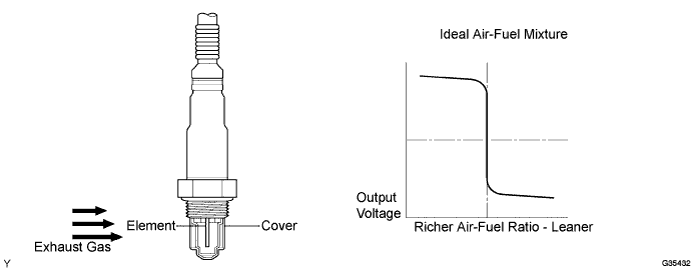

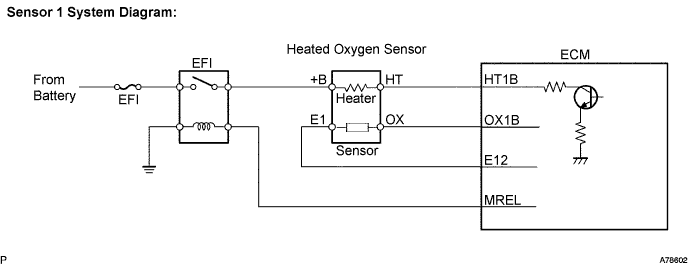

In order to obtain a high purification rate for the carbon monoxide (CO), hydrocarbon (HC) and nitrogen oxide (NOx) components in the exhaust gas, a Three-Way Catalytic Converter (TWC) is used. For the most efficient use of the TWC, the air-fuel ratio must be precisely controlled so that it is always close to the stoichiometric air-fuel ratio. The heated oxygen sensor has the characteristic whereby its output voltage changes suddenly in the vicinity of the stoichiometric air-fuel ratio. This is used to detect the oxygen concentration in the exhaust gas and provide the ECM with feedback to control the air-fuel ratio. When the air-fuel ratio becomes lean, the oxygen concentration in the exhaust gas increases. The heated oxygen sensor informs the ECM of the lean condition (low voltage, i.e. less than 0.45 V). When the air-fuel ratio is richer than the stoichiometric air-fuel level, the oxygen concentration in the exhaust gas is reduced. And the heated oxygen sensor informs the ECM of the rich condition (high voltage, i.e. more than 0.45 V). The ECM judges by the voltage output of the heated oxygen sensor whether the air-fuel ratio is rich or lean and controls the injection time accordingly. If a malfunction of the heated oxygen sensor causes an output of abnormal voltage, the ECM is unable to perform accurate air-fuel ratio control. The heated oxygen sensor includes a heater which heats the zirconia element. The heater is controlled by the ECM. When the intake air volume is low (the temperature of the exhaust gas is low), a current flows to the heater in order to heat the sensor for accurate oxygen concentration detection.

| DTC No. | DTC Detection Condition | Trouble Area |

|---|---|---|

| P0138 | Heated oxygen sensor (sensor 2) output voltage is 1.5 V or more continuously for 5.1 seconds (3 trip detection logic) |

|

Tech Tips

-

Sensor 2 refers to the sensor farthest away from the engine assembly.

-

The normal output voltage from the heated oxygen sensor (sensor 2) is 0 to 1.0 V.

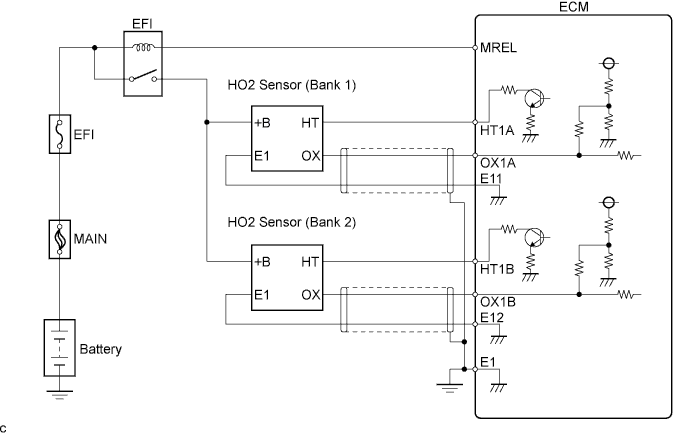

WIRING DIAGRAM

CONFIRMATION DRIVING PATTERN

DTC P0138 is detected when the vehicle is driven at an average vehicle speed of approximately 50 km/h (31 mph) in the city for approximately 30 minutes.

INSPECTION PROCEDURE

Tech Tips

Read the heated oxygen sensor (sensor 2) output voltage using the intelligent tester.

-

INSPECT HEATED OXYGEN OXYGEN SENSOR OUTPUT VOLTAGE

-

Connect the intelligent tester to the DLC3.

-

Start the engine and turn the intelligent tester ON.

-

Select the following menu items: Powertrain / Engine and ECT / Data List / O2S B1 S2.

-

Read the output voltage of the heated oxygen sensor.

-

PROCEDURE

-

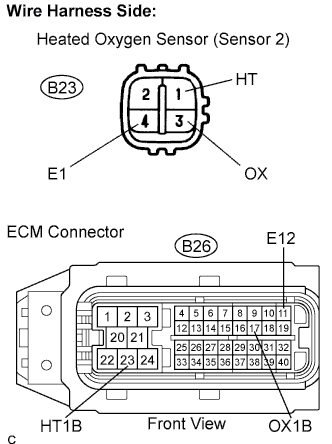

CHECK HARNESS AND CONNECTOR (HEATED OXYGEN SENSOR (SENSOR 2) - ECM)

-

Disconnect the B23 heated oxygen sensor connector (sensor 2).

-

Disconnect the B26 ECM connector.

-

Measure the resistance.

Standard resistance (Check for short) Tester Connector Specified Condition OX (B23-3) or OX1B (B26-17) - HT (B23-1) or HT1B (B26-23) 10 kΩ or higher OX (B23-3) - +B (B23-2) 10 kΩ or higher -

Reconnect the heated oxygen sensor connector.

-

Reconnect the ECM connector.

NG

REPAIR OR REPLACE HARNESS AND CONNECTOR

OK

REPLACE HEATED OXYGEN SENSOR (SENSOR 2)

-