DIRECT CLUTCH DISASSEMBLY

-

INSPECT PISTON STROKE OF DIRECT CLUTCH

-

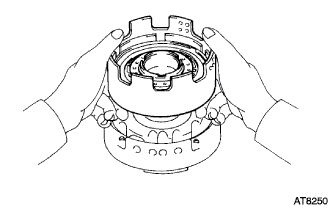

Place the direct clutch assembly onto the O/D support assembly.

-

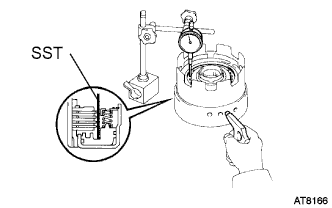

Using SST and a dial indicator, measure the direct clutch piston stroke while applying and releasing compressed air (392 to 785 kPa, 4.0 to 8.0 kgf/cm2, 57 to 114 psi).

- SST

- 09350-30020 ( 09350-06120 )

Piston stroke 1.37 to 1.60 mm (0.0539 to 0.0630 in.) If the piston stroke is less than the limit, parts may have been assembled incorrectly, so check and reassemble again.

If the piston stroke is outside the standard, select another flange.

Tech Tips

There are 8 different thicknesses for the flange.

Flange thickness: No. Thickness No. Thickness 53 3.3 (0.130) 57 3.7 (0.146) 54 3.4 (0.134) 58 3.8 (0.150) 55 3.5 (0.138) 60 4.0 (0.157) 56 3.6 (0.142) 62 4.2 (0.165)

-

-

REMOVE DIRECT CLUTCH

-

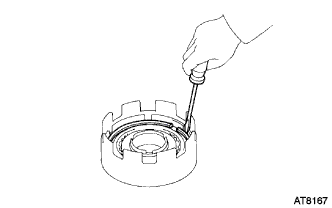

Using a screwdriver, remove the snap ring from the direct clutch drum.

-

Remove the flange, plates and discs.

-

-

INSPECT DIRECT CLUTCH FLANGE

-

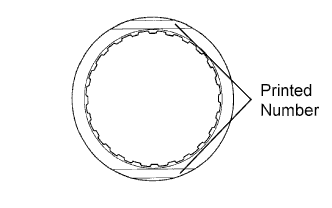

Check if the sliding surfaces of the disc, the plate and the flange are worn or burnt. If necessary, replace them.

Tech Tips

If the lining of the disc is peeled off or discolored, or even if only a part of the printed numbers is corroded, replace all discs.

-

-

REMOVE DIRECT CLUTCH RETURN SPRING SUB-ASSEMBLY

-

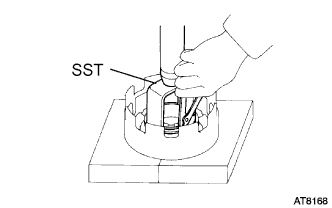

Place SST on the spring retainer, and compress the piston return spring with a press.

- SST

- 09350-30020 ( 09350-07040 )

-

Using SST, remove the snap ring.

- SST

- 09350-30020 ( 09350-07070 )

-

Remove the return spring.

-

-

INSPECT DIRECT CLUTCH RETURN SPRING SUB-ASSEMBLY

-

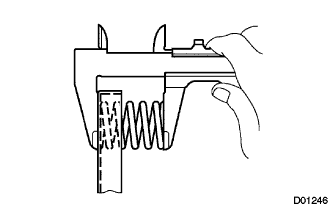

Measure the free length of the spring together with the spring seat.

Standard free length 21.32 mm (0.8394 in.)

-

-

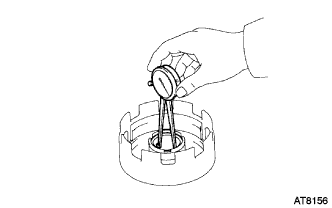

REMOVE DIRECT CLUTCH PISTON SUB-ASSEMBLY

-

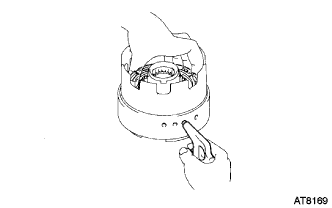

Place the direct clutch drum onto the O/D support.

-

Hold the direct clutch piston, and apply compressed air to the O/D support to remove the direct clutch piston.

-

Remove the 2 O-rings from the piston.

-

-

INSPECT DIRECT CLUTCH PISTON SUB-ASSEMBLY

-

Check that the check ball is free by shaking the piston.

-

Check that the valve does not have leaks by applying low-pressure compressed air.

-

-

INSPECT DIRECT CLUTCH DRUM SUB-ASSEMBLY

-

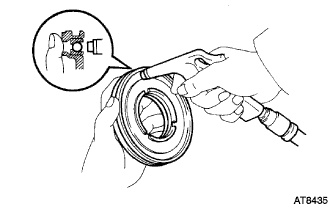

Using a dial indicator, measure the inside diameter of the clutch drum bushing.

Maximum inside diameter 53.99 mm (2.1256 in.) If the inside diameter is greater than the maximum, replace the clutch drum.

-