STOP AND START SYSTEM DATA LIST / ACTIVE TEST

-

DATA LIST

Tech Tips

Using the GTS to read the Data List allows the values or states of switches, sensors, actuators and other items to be read without removing any parts. This non-intrusive inspection can be very useful because intermittent conditions or signals may be discovered before parts or wiring is disturbed. Reading the Data List information early in troubleshooting is one way to save diagnostic time.

Note

In the table below, the values listed under "Normal Condition" are reference values. Do not depend solely on these reference values when deciding whether a part is faulty or not.

-

Warm up the engine.

-

Turn the ignition switch off.

-

Connect the GTS to the DLC3.

-

Start the engine.

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Stop and Start / Data List.

-

Check the values by referring to the table below.

Tech Tips

The results of a test performed on an actual vehicle are shown in the "Result of Real-vehicle Check" column. Use these values as a reference.

Stop and Start Tester Display Measurement Item Range Normal Condition Diagnostic Note Eco Warning Stop and start indicator light status ON / OFF ON: Idling stop being performed

OFF: Idling stop not being performed (When system is normal)

ON: Any malfunction occurs in the system and the stop and start indicator light is blinking. Coolant Temp Engine coolant temperature Min.: 16°C (60.8°F), Max.: 127°C (260.6°F) 75 to 100°C (167 to 212°F): After warming up This is sent from the ECM. Engine Spd (ECM) Engine speed signal from ECM via CAN communication Min.: 0 rpm, Max.: 12800rpm

-

680 to 780 rpm: Idling after engine warmed up*1, *3

-

550 to 650 rpm: Idling after engine warmed up*2, *3

-

730 to 830 rpm: Idling after engine warmed up*4

-

720 to 820 rpm: Idling after engine warmed up*5

This is sent from the ECM. Engine Spd (NE Signal) Engine speed signal from ECM via direct line Min.: -25600 rpm, Max.: 25599 rpm

-

680 to 780 rpm: Idling after engine warmed up*1, *3

-

550 to 650 rpm: I dling after engine warmed up*2, *3

-

730 to 830 rpm: Idling after engine warmed up*4

-

720 to 820 rpm: Idling after engine warmed up*5

The pulse signal sent is from NEO terminal of the ECM. Deceleration Sens Offset Val Deceleration sensor offset value Min.: -1176.008 m/s2, Max.: 1176.007 m/s2 -0.903 to 0.903 m/s2: After deceleration sensor zero point learning completion - Deceleration Sens Calibration Deceleration sensor calibration status Incmpl / Running / Compl / Err1 / Err2 / Err3 Compl: After deceleration sensor zero point learning completion - Gradient of Road Surface Degree of road gradient Min.: -10.24 m/s2, Max.: 10.16 m/s2

-1.4 to 1.4 m/s2: Vehicle stopped on level surface

-

-0.7 - 0.7 m/s2(Vehicle stopped on level surface)

-

-0.7 m/s2or less / 0.7 m/s2or more (Vehicle stopped on slope)

Battery Voltage VB voltage Min.: 0 V, Max.: 65.535 V 9 to 14 V: Idling - Battery Fluid Temperature Battery fluid temperature Min.: -40°C (-40°F), Max.: 100°C (212°F) Changes according to actual temperature: Driving after engine warmed up - Battery Temp (Start) Battery temperature at engine start Min.: -40°C (-40°F), Max.: 100°C (212°F) Same as temperature around battery at engine start (after engine start) - Oper Permission (AT/CVT) Permission of stop and start control by continuously variable transaxle system*1 NG / OK OK: CVT system normal and CVT fluid temperature 25°C to 103°C (77°F to 217.4°F) This is sent from the ECM via CAN communication. Oper Permission (AT/CVT 2) Permission of stop and start control by continuously variable transaxle system*1 NG / OK OK: Oil pump with motor assembly normal This is sent from the ECM via CAN communication. Engine Type Information Information on the engine type from the SFI*3, *4 or ECD*5 system Avail / Not Avl Avail: Information of engine type received from ECM through CAN communication Not Avl is displayed if improper engine type information is received from the ECM via CAN communication. Starter Type Starter assembly type Other than Tandem Starter / Tandem Starter - - D Courtesy Switch Signal Driver door courtesy switch signal ON / OFF ON: Driver side door open

OFF: Driver side door closed

- Hood Courtesy Switch Hood courtesy switch signal ON / OFF ON: Engine hood closed

OFF: Engine hood opened

- Neutral Switch Park/neutral position switch*1 or neutral position switch*2 status ON / OFF ON: Shift lever in P or N (neutral)

OFF: Shift lever not in P or N (neutral)

- Clutch Upper SW Clutch switch assembly signal*2 ON / OFF ON: Clutch pedalfully released

OFF: Clutch pedal depressed

- Clutch Lower SW Clutch start switch assembly signal*2 ON / OFF ON: Clutch pedalfully depressed

OFF: Clutch pedal released

- Starter Starter status ON / OFF ON: Cranking

OFF: Not cranking

- Pinion Gear Starter pinion status ON / OFF ON: Starter pinion operated

OFF: Starter pinion not operated

- Starter Motor Starter motor status*1 ON / OFF ON: Cranking

OFF: Not cranking

- TC Terminal TC and CG terminals of DLC3 ON / OFF ON: TC and CG terminals of DLC3 connected

OFF: TC and CG terminals of DLC3 disconnected

- Cancel Switch Stop and start system cancel switch signal ON / OFF ON: Stop and start system cancel switch pressed

OFF: Stop and start system cancel switch not pressed

- IG Switch Ignition or starter switch assembly ON / OFF ON: Ignition switch ON - Idle Engine idling status ON / OFF ON: Accelerator pedal fully released

OFF: Accelerator pedal depressed

This is sent from the ECM. Engine Start (IG SW) Engine start by ignition or starter switch assembly operation ON / OFF ON: Engine start by ignition or starter switch assembly operation

OFF: Except engine start by ignition or starterswitch assembly operation

Indicates starter operation by operation of the ignition or starter switch assembly Stop Light SW (ECM) Stop light switch assembly signal from ECM ON / OFF ON: Brake pedal depressed

OFF: Brake pedal released

This is sent from the ECM. Stop Light SW (ABS/ VSC) Stop light switch assembly signal from vehicle stability control system ON / OFF ON: Brake pedal depressed

OFF: Brake pedal released

This is sent from the skid control ECU (brake actuator assembly). Engine Starter Signal Starter signal status ON / OFF ON: Cranking

OFF: Not cranking

This is sent from the ECM. Buzzer Buzzer status ON / OFF ON: Buzzer ON

OFF: Buzzer does not sound

Refer to warning buzzer operation conditions. Indicat. Light Eco Stop and start indicator light status ON / OFF ON: Stop and start indicator light on or blinking

OFF: Stop and start indicator light off

- Oil Prs Warn Light Prohibit Oil pressure warning light status Permit / Prohibit Prohibit: During engine stop by stop and start control Permit: Not during engine stop by stop and start control Engine stop and start ECU informs the combination meter assembly that the oil pressure warning light does not come on during engine stop by stop and start control. Brake Press Hold Req Brake fluid pressure holding request during stop and start control*1

ON/OFF

ON / OFF ON: Shift lever in D and engine stop ped by stop and start control

OFF: Shift lever in D and engine not stopped by stop and start control

ON is displayed when a brake fluid pressure holding request is sent during stop and start control or the engine is stopped by stop and start control with the shift lever in D. Brake Pressure Hold Request Status Brake fluid pressure holding status during stop and start control*1 Normal Release / Quick Release / Hold / Immediate Release - - S&S Cancel Light Code Transmission code from the engine stop and start ECU to the combination meter assembly 0: extinction /1: lighting / 2: blink / 3: - / 4: DTC output 0: Stop and start cancel indicator light off

1: Stop and start cancel indicator light on

Stop and start cancel indicator light on/blinking/off request sent to combination meter assembly. Starter Operation # Number of starter operations (count record) Min.: 0, Max.: 1048575 - - Number of Engine Starts (IG-ON) The number of starter operations by ignition or starter switch assembly operation Min.: 0, Max.: 16777215 - - Number of Engine Starts (Stop & Start) The number of starter operations by stop and start control Min.: 0, Max.: 16777215 - - Number of Engine Starts (Clutch Released) The number of starter operations without clutch pedal being depressed*2 Min.: 0, Max.: 16777215 - - Number of Engine Starts (Clutch Half-Depressed) The number of starter operations with clutch pedal depressed halfway*2 Min.: 0, Max.: 16777215 - - Vehicle Spd1 (ABS/ VSC) Vehicle speed signal from skid control ECU via CAN communication Min.: 0 km/h(0 mph), Max.: 327.67 km/h (203.6 mph) 0 km/h (0 mph): Vehicle stopped - Steering Angle Steering angle Min.: -49152 deg, Max.: 49150.5 deg - - Steering Angle Velocity Steering wheel turning speed Min.: -32768 deg/s, Max.: 32767 deg/s - - Battery Current Battery current Min.: -125 A, Max.: 124.99 A - - Brake Negative Pressure Brake booster vacuum (negative pressure) Min.: -640 kPa (-4800 mmHg, -188 in.Hg)

Max.: 639.98 kPa (4800 mmHg, 188 in.Hg)

Approx. 0 kPa (0 mmHg, 0in.Hg): Ignition switch ON, brake pedal depressed several times This item cannot be checked if a malfunction occurs in communication with ECM. Ambient Temp Sensor Ambient temperature Min.: -80°C (-112°F), Max.: 79.9°C (175.8°F) Close to ambient temperature - Stop&Start of Eng State Stop and start control status IG / Run / Stopreq / Stop / Restart

-

IG: Engine stopped

-

Run: Engine running

-

Stopreq: Engine stop requested

-

Stop: Engine stopped (by stop and start control)

-

Restart: Engine restarted

- Stop & Start A/C Mode Selected air conditioning mode Undefined / Normal / S&S Prioritized / A/C Prioritized - - Idling Stop Rate Rate of idling stop time to entire ignition switch ON time of this trip Min.: 0%, Max.: 100% - - Total Idling Stop Rate Rate of total idling stop time until now Min.: 0%, Max.: 100% - - Integrated Current Battery integrated current Min.:-268434.45 A -sec, Max.: 268435.45 A- sec Differs according to vehicle condition (charge/ discharge conditions) Refer to "Regarding Battery Integrated Current" below for details.*3 Cranking Time Engine cranking time Min.: 0 ms, Max.: 134215ms 300 to 3000 ms: Duration of starter operation by stop and start control - Min Voltage (Cranking) Minimum voltage when cranking engine Min.: 0 V, Max.: 327.67 V 6 to 11 V Lowest battery voltage measured in a 5 second period after the starter starts operating Min Volt (After Cranking) Minimum voltage when starter begins operation Min.: 0 V, Max.: 327.67 V 6 to 11 V Minimum battery voltage while the starter starts operating Master Cylinder Pressure Brake fluid pressure*1 Min.: 0 MPa, Max.: 327.67 MPa 0 to 5 MPa (when normal pedal effort is applied) - Status of Battery Charge Control Battery charge control status Charge Control Coordination Mode / Stop and Start Standalone Mode / Refresh Charge Mode / Stop and Start Restriction Mode / Temperature High/Low Mode / Abnormal Mode / Battery Condition Judgment Mode / Low Temperature Mode - - State of BBC Backup boost converter status Cycle Err / Overvol / Overload / Normal / Low Vol / Duty Err / S&S Sensor Electric Supply Low / S&S CPU Malfunction / BBC Overcurrent / S&S Starter Overcurrent / S&S Reduced Voltage Reset Normal: Backup boost converter operating normally

-

Duty Err:

-

Abnormal duty ratio is detected.

-

Cycle Err:

-

Abnormal output voltage cycle is detected.

-

Low Vol:

-

A decrease in the voltage of the control IC power source within the backup boost converter is detected when ignition switch is turned to ON.

-

Overload:

-

Overcurrent is detected.

-

Overvol:

-

When the ignition switch is ON:

-

Overvoltage is detected at the control IC power source in the backup boost converter

-

Overheating is detected at the control IC power source in the backup boost converter

-

When boosting:

-

Malfunction is detected in the feedback circuit in the backup boost converter

-

Too high or low output voltage.

BBC Check Result Backup boost converter check result Normal / Abnormal Normal: Backup boost converter normal Abnormal is displayed if excessive electrical load is applied to the converter at engine start. Atmosphere Pressure Atmospheric pressure (calculated value) Min.: 0 kPa (0 kgf/cm2, 0 psi), Max.: 255 kPa (2.6 kgf/cm2, 37 psi)

Approx. 100 kPa (1.0 kgf/cm2, 15 psi): Ignition switch ON (close to actual atmospheric pressure)

ECM calculated value Barometric Pressure Circuit Voltage Barometric pressure circuit voltage Min.: 0 V, Max.: 4.99 V - - EPS Load Electric power steering current Min.: -327.68A, Max.: 327.67 A Approx. 0 A: EPS assist not activated - Accelerator Position Accelerator pedal position Min.: 0%, Max.: 127.5% Actual accelerator pedal position - Shift Position Shift lever position*1 Unset / B / D / R / N / P Shift lever position - Engine OFF Request Engine stop request ON / OFF ON: During engine stop by stop and start control

OFF: Not during engine stop by stop and start control

ON is displayed when fuel-cut is performed by stop and start control, engine start is not requested, or starter is forced to operate. Manual Start during S&S Manual start during stop and start control operation*2 ON / OFF - - Wrong Operation (Start) Incorrect operation for engine start ON / OFF - Unused N/Clutch Lower SW Abnoml Clutch start switch assembly (for lower)*2 ON / OFF - - N/Clutch Upper SW Abnoml Clutch switch assembly (for upper)*2 ON / OFF - - Permit Idling Stop Engine stop standby ON / OFF - - Running History Vehicle driving record ON / OFF ON: History of driving vehicle at 2 km/h (1 mph) or more (without DTC output) Turns OFF when the engine is stopped by stop and start control. Simple-IPA Available Availability of simple-IPA system on vehicle No / Yes - Unused Air Suspension Available Availability of air suspension system on vehicle No / Yes - Unused Welcab Available Availability of side lift up seat system on vehicle No / Yes - Unused PCS Available Availability of pre-crash safety system on vehicle No / Yes - - External BBC Available Availability of eco run vehicle converter assembly (external backup boost converter) on vehicle No / Yes No: Eco run vehicle converter assembly (external backup boost converter) not equipped

Yes: Eco run vehicle converter assembly (external backup boost converter) equipped

- ACC Available Availability of dynamic radar cruise control system on vehicle*1 No / Yes - Unused Brake Hold Function Available Availability of brake hold function on vehicle No / Yes Yes: Brake hold function available - Steering Angle Sensor Available Availability of steering angle sensor on vehicle No / Yes Yes: Equipped with steering angle sensor - Steering Angle Sensor Malfunction Steering angle sensor (spiral cable with sensor sub-assembly) malfunction ON / OFF OFF: Normal - Steering Angle Sensor Circuit Open (+B) Steering angle sensor (spiral cable with sensor sub-assembly) +B circuit malfunction ON / OFF OFF: Normal - Steering Angle Sensor Abnormal Value Steering angle sensor (spiral cable with sensor sub-assembly) value malfunction ON / OFF OFF: Normal - EPS Current Enable on Assist Power steering assist current value determination Avail / Not Avail Avail: Power assist current valid - Auto A/C Availability of air conditioning system on vehicle Without / With With: Equipped with air conditioning system

Without: Not equipped with air conditioning system

Air conditioning information needs to be registered after engine stop and start ECU replacement. Barometric Pressure Circuit Available Existence of the barometric pressure circuit No / Yes - - Eng Start Req (A/C 2) Engine start request from the air conditioning system ON / OFF ON: Engine start requested to ensure air conditioning system performance

OFF: Engine start not requested to ensure air conditioning system performance

- Wheel Speed Malfunction Wheel speed sensor malfunction status ON / OFF OFF: Input value from speed sensor is normal ON remains displayed when any input values from the wheel speed sensors are abnormal. Slip History Slip history existence*1 Without / With - - Battery Type Set battery type Specified / Other Specified: Specified battery Other: Non-specified battery - E/G ECU Region Mismatch ECM region mismatch status ON / OFF OFF: ECM destination information is matched. - Power Train Output Request Method Method of power train output request Driving Force / Not Driving Force - - Oil Pump Relay Oil pump motor relay inside ECU status*1 ON / OFF ON: Oil pump motor relay inside ECU is on - Oil Pump Status Oil pump with motor assembly status*1 ON / OFF ON: Oil pump with motor assembly operating

OFF: Oil pump with motor assembly not operating

ON is displayed while the engine is stopped by stop and start control Oil Pump Duty Requested oil pump with motor assembly duty*1 Min.: -32767%, Max.: 32767% 65%: Oil pump with motor assembly is operating - State of Oil Pump Motor Rotation Oil pump with motor assembly rotation status*1 Low / High Low: Rotating at low speed

High: Rotating at high speed

- Oil Pump Motor Rotation Frequency Oil pump with motor assembly rotation frequency*1 Min.: -32768 Hz, Max.: 32767 Hz 17 to 200 Hz - Oper Permission (Shift D position) Permission of stop and start control based on shift lever position (D)*1 NG / OK OK: Vehicle being driven with shift lever in D - Oper Permission (Neutral Switch) Permission of stop and start control based on the neutral position switch conditions NG / OK OK: Shift lever in neutral - Oper Permission (Idling) Permission of stop and start control based on the engine idle conditions NG / OK OK: Engine idling (engine speed below 1250 rpm) without accelerator pedal being depressed - Oper Permission (Vehicle Speed) Permission of stop and start control based on the vehicle speed conditions NG / OK OK: Vehicle stopped OK is displayed while vehicle is stopped. Stop&Start Precondition Permission of stop and start control with all preconditions met ON / OFF ON: Preconditions for stop and start control have been met Condition of permission or prohibition for terms listed below.

(ECM1, ECM2, battery, ABS/ VSC2, IGSW, DTC, A/C, interval, after running, engine hood closed, D door closed, cancel switch, AT/CVT, AT/ CVT2, interval for starter, key operation, driver side buckle SW, ambient temperature)

For details on the preconditions, refer to System Description.

Stop&Start Precondition 2 Permission of stop and start control with all preconditions met ON / OFF ON: Preconditions for stop and start control have been met Condition of permission or prohibition for terms listed below.

(Idling, road surface gradient, no shift operation, brake negative pressure, steering, O/P check, starter check complete)

Oper Permission (Master Cylinder Pressure) Permission of stop and start control based on master cylinder pressure*1 NG / OK OK: Brake pedal depressed while vehicle stopped - Oper Permission (ECM 1) Permission of stop and start control by the ECM NG / OK OK: Stop and start control enabled (SFI system and CVT system is normal) - Oper Permission (ECM 2) Permission of stop and start control by SFI system NG / OK OK: Stop and start control enabled (SFI system is normal) This is sent from the ECM through CAN communication Oper Permission (IG SW) Permission of stop and start control based on the ignition or starter switch assembly conditions NG / OK OK: Ignition switch ON for 5 seconds - Oper Permission (DTC) Permission of stop and start control based on the DTC output conditions NG / OK OK: DTC not output - Oper Permission (O/P Check) Permission of stop and start control based on oil pump with motor assembly condition*1 NG / OK OK: Oil pump with motor assembly normal - Oper Permission (Brake Negative Pressure) Permission of stop and start control based on the brake booster vacuum conditions NG / OK OK: Brake vacuum is 31.5 kPa (236 mmHg, 9.3 in.Hg) to 56.8 kPa (426 mmHg, 16.8 in.Hg) or more for 1 second or longer - Oper Permission (Interval) Permission of stop and start control based on the engine running time conditions NG / OK OK: A certain period of time has elapsed after starter operation - Oper Permission (D Door Closed) Permission of stop and start control based on the driver door open/ close conditions NG / OK OK: Engine hood closed - Oper Permission (Engine Hood Closed) Permission of stop and start control based on the engine hood open/ close conditions NG / OK OK: Engine hood closed - Oper Permission (A/C) Permission of stop and start control based on the air conditioning conditions NG / OK OK: Air conditioning conditions met - Oper Permission (Ambient Temperature) Permission of stop and start control based on the air conditioning conditions NG / OK OK: Ambient temperature -5°C (23°F) or higher - Oper Permission (ABS/VSC) Permission of stop and start control by vehicle stability control system*1 NG / OK OK: Stop and start control permitted based on vehicle stability control system normal condition, or Active Test (forced permission) performed - Oper Permission (No Shift Operation) Permission of stop and start control based on shift lever operation condition*1 NG / OK OK: Shift lever not moved for 1 second or more - Oper Permission (After Running) Permission of stop and start control based on the initial trip conditions after the ignition switch is turned to ON NG / OK OK: Vehicle has been driven at 7 km/h (4 mph) or more OK is displayed after the initial trip until the ignition switch is turned off. Oper Permission (Neutral SW OFF History) Permission of stop and start control based on the shift operation history*2 NG / OK OK: Neutral position switch OFF record is detected (remains ON until next stop and start system control) - Oper Permission (Clutch Upper SW OFF History) Permission of stop and start control based on the clutch pedal operation history*2 NG / OK OK: Clutch pedal depressed - Oper Permission (Battery) Permission of stop and start control based on the battery conditions NG / OK OK: Stop and start control permitted based on battery conditions, or Active Test (forced permission) performed - Oper Permission (Start Min Volt 1) Permission of stop and start control based on minimum voltage during starting when battery fluid temperature is 0°C (32°F) or less NG / OK OK: Battery temperature is 0°C (32°F) or less and minimum voltage when cranking is equal to the threshold or higher If 2 or more of Start Min Volt 1, 2, 3, or 4 are OK, stop and start control is permitted Oper Permission (Start Min Volt 2) Permission of stop and start control based on minimum voltage during starting when battery fluid temperature is more than 0°C (32°F) NG / OK OK: Battery temperature is 0°C (32°F) or less and minimum voltage when starter begins operation is equalto the threshold or higher If 2 or more of Start Min Volt 1, 2, 3, or 4 are OK, stop and start control is permitted Oper Permission (Start Min Volt 3) Permission of stop and start control based on minimum voltage after cranking when battery fluid temperature is 0°C (32°F) or less NG / OK OK: Battery temperature is 0°C (32°F) or lower and the minimum voltage right after engine cranking is the threshold value or higher If 2 or more of Start Min Volt 1, 2, 3, or 4 are OK, stop and start control is permitted Oper Permission (Start Min Volt 4) Permission of stop and start control based on minimum voltage after cranking when battery fluid temperature is more than 0°C (32°F) NG / OK OK: Battery temperature is higher than 0°C (32°F) and minimum voltage when starter begins operation is equal to the threshold or higher If 2 or more of Start Min Volt 1, 2, 3, or 4 are OK, stop and start control is permitted Oper Permission (Battery Current) Permission of stop and start control based on battery current NG / OK OK: Battery discharge current is -125 A or higher Engine stop and start ECU calculated value Oper Permission (Integrated Current) Permission of stop and start control based on the integrated current value conditions NG / OK OK: Integrated current value is equal to the threshold or more The status depends on the value of "Integrated Current", and the OK/NG threshold differs according to the battery temperature.

Refer to "Regarding Battery Integrated Current" below for details.*6

Oper Prohibition (Jump Start) Prohibition of stop and start control based on the jump start conditions Permit / Prohibit Prohibit: Engine started with the engine hood open and the ignition switch turned to ON When Prohibit is displayed, stop and start control will be prohibited until the ignition switch is turned off. Oper Prohibition (Manual Start) Prohibition of stop and start control based on the manual start conditions*2 Permit / Prohibit Prohibit: During manual start When Prohibit is displayed, stop and start control will be prohibited until the ignition switch is turned off.

Conditions for Manual Start:

-

Clutch start switch OFF or vehicle speed signal input

-

Neutral position switch OFF

-

Starter signal OFF

Oper Permission (Interval For Starter) Permission of stop and start control based on the conditions after engine restart NG / OK OK: 4 minutes or less have elapsed after engine restarted - Oper Permission (Cancel Switch) Permission of stop and start control based on the stop and start system cancel switch operation NG / OK OK: Stop and start control is permitted (stop and start cancel indicator light is not illuminated) - Oper Permission (ABS/VSC 2) Permission of stop and start control by vehicle stability control system*1 NG / OK OK: Stop and start control permitted based on vehicle stability control system normal condition, or Active Test (forced permission) performed - Oper Permission (Road Surface Gradient) Permission of stop and start control based on the road grade conditions NG / OK OK: Vehicle stopped on level road (not steep grade) - Oper Permission (Driver Side Buckle SW) Permission of stop and start control based on the driver seat belt condition NG / OK OK: The driver side buckle switch fastened - Oper Permission (Steering) Permission of stop and start control by the power steering ECU assembly NG / OK OK: EPS system is normal - Oper Prohibition (Shift Position Uncertain) Prohibition of stop and start control based on shift lever position*1 Permit / Prohibit Permit: Shift lever position determined - Oper Permission (Key Operation) Permission of stop and start control based on the ignition or starter switch assembly operation NG / OK OK: Ignition or starter switch assembly not operated - Oper Permission (Starter Check Complete) Permission of stop and start control based on the starter circuit self- check result NG / OK OK: Stop and start control enabled (starter circuit normal) When the engine stop and start ECU is abnormal, the starter drive circuit is judged to be abnormal, and NG is displayed Oper Permission (Brake Master Pressure 0 Point) Permission of stop and start control due to completion of brake master cylinder pressure zero point calibration*1 NG / OK OK: Brake master cylinder pressure zero point calibration completed normally - Oper Permission (Simple-IPA Button) Permission of stop and start control by simple-IPA system NG / OK - Unused Oper Prohibition (Engine F/C) Prohibition of stop and start control based on the engine fuel-cut prohibition signal Permit / Prohibit Permit: Fuel-cut permitted by SFI system - Oper Permission (Air Suspension) Prohibition of stop and start control based on air suspension system NG / OK - Unused Oper Permission (Welcab) Prohibition of stop and start control based on side lift up seat system NG / OK - Unused Oper Permission (PCS) Prohibition of stop and start control based on pre-crash safety system NG / OK - - Oper Permission (ACC) Prohibition of stop and start control based on dynamic radar cruise control system *1 NG / OK - - Eng Start Req (Vehicle Speed Input) Engine start request based on vehicle speed signal input ON / OFF ON: Engine start requested based on speed signal input while engine stopped by stop and start control - Eng Start Req (Air Suspension/Welcab) Engine start request based on air suspension system and side lift up seat system ON / OFF - Unused Eng Start Req (Brk Negative Pressure Low) Engine start request due to low brake booster vacuum ON / OFF ON: Brake booster vacuum insufficient while engine stopped by stop and start control

-

OFF is usually displayed

-

ON is displayed when the engine is started due to decreased brake booster vacuum caused by depressing the brake pedal several times

Eng Start Req (IG Switch) Engine start request due to ignition or starter switch assembly operation ON / OFF ON: Engine started using ignition or starter switch assembly while engine stopped by stop and start control - Eng Start Req (ABS/ VSC) Engine start request from vehicle stability control system ON / OFF ON: Engine startr equested by skid control ECU (brake actuator assembly) - Eng Start Req (ECM) Engine start request from ECM ON / OFF ON: Engine start requested by ECM - Eng Start Req (A/C) Engine start request from Air conditioning system ON / OFF ON: Engine start requested by air conditioning system - Eng Start Req (Accelerator) Engine start request due to accelerator pedal operation*1 ON / OFF ON: Engine start requested due to accelerator pedal being depressed - Eng Start Req (Brake Release) Engine start request due to brake pedal operation*1 ON / OFF ON: Engine start requested due to brake pedal being released - Eng Start Req (Shift Lever) Engine start request due to shift lever operation*1 ON / OFF ON: Engine start requested due to operation of shift lever - Eng Start Req (Steering) Engine start request by the power steering system ON / OFF ON: Power steering assist current is abnormal - Eng Start Req (AT/ CVT) Engine start request from continuously variable transaxle system*1 ON / OFF ON: Engine start requested by continuously variable transaxle system - Eng Start Req (Detect DTC) Engine start request due to output of DTCs ON / OFF ON: Engine start requested due to output of stop and start system DTCs - Eng Start Req (Shift Uncert) Engine start request due to uncertain shift lever position*1 ON / OFF ON: Engine start requested due to uncertain shift lever position while engine is stopped by stop and start control - Eng Start Req (Clutch Pedal) Engine start request by the clutch pedal*2 ON / OFF ON: Clutch pedal is depressed - Eng Start Req (Clutch Lower SW) Engine start request by the clutch start switch assembly (for lower)*2 ON / OFF ON: Clutch pedal is fully depressed - Eng Start Req (Engine Hood Open) Engine start request due to opening of engine hood ON / OFF ON: Engine start requested due to engine hood being opened while the engine is stopped by stop and start control - Eng Start Req (Battery Condition) Engine start request based on battery performance ON / OFF ON: Engine start requested due to low battery voltage while the engine is stopped by stop and start control - Eng Start Req (CVT Vehicle Speed) Engine start request based on vehicle speed signal from the CVT system ON / OFF - Unused Eng Start Req (ABS Vehicle Speed) Engine start request based on vehicle speed signal from the vehicle stability control system ON / OFF ON: Engine start requested due to speed signal while the engine is stopped by stop and start Engine start request based on the speed sensor signal Eng Start Req (Cancel SW) Engine start request by stop and start system cancel switch ON / OFF ON: Engine start requested due to operation of the stop and start system cancel switch while the engine is stopped by stop and start control - Eng Start Req (Simple-IPA) Engine start request from simple-IPA system ON / OFF - Unused Eng Start Req (Courtesy SW or Buckle SW) Engine start request by courtesy switch (for driver side) or driver side buckle switch ON / OFF ON: Engine start requested due to operation of the courtesy switch (for driver side) or driver side buckle switch while the engine is stopped by stop and start control - Oper Prohibition (Panic Brake) Prohibition of stop and start control due to sudden braking*1 Permit / Prohibit Permit: Sudden braking not performed - ABS Running Operating condition of the vehicle stability control system ON / OFF ON: Vehicle stability control system operating - Clutch SW Signal Abnoml Status of the Clutch SW Signal Abnormal*2 ON / OFF - - Crank Pos Sen Abnoml 3 Status of the crankshaft position sensor abnormal ON / OFF - - N Position Switch Neutral position switch status*2 ON / OFF OK: System normal - Brk Boost Sen Abnoml 2 Status of vacuum sensor abnormal ON / OFF - - Brk Boost Sen Abnoml 3 Status of vacuum sensor abnormal ON / OFF - - Starter Count Abnoml Status of starter count abnormal ON / OFF - - Starter Circuit Abnoml Status of starter circuit abnormal ON / OFF - - Starter Circuit Open Status of starter circuit open ON / OFF - - Neutral SW Abnoml (ON) Status of neutral position switch abnormal*1 ON / OFF - - Neutral SW Abnoml (OFF) Status of neutral position switch abnormal*1 ON / OFF - - Alternator Status Generator power generation status Normal /Abnormal Normal: Generator operation normal - BBC Abnoml Status of backup boost converter abnormal ON / OFF - - BBC Overcurrent Status of backup boost converter over current ON / OFF - - BBC Duty Status of backup boost converter duty ON / OFF - - BBC Power Low Status of backup boost converter power low ON / OFF - - BBC Over Heat Status of backup boost converter over heat ON / OFF - - BBC Thermistor Status of backup boost converter thermistor Normal /Abnormal - - Barometric Pressure Circuit Open/Short Status of barometric pressure circuit open or short ON / OFF - - IG SW Abnoml Status of ignition or starter switch assembly ON / OFF - - Battery Abnoml Status of power source ON / OFF - - Sensor Supply Voltage Low Status Status of drop in sensor power source voltage ON / OFF - - Comm Err with ECM Communication error with ECM ON / OFF - - Comm Err with ABS/VSC Communication error with skid control ECU (brake actuator assembly) ON / OFF - - Comm Err with EPS Communication error with power steering ECU assembly ON / OFF - - Comm Err with J/B Communication error with main body ECU (multiplex network body ECU) ON / OFF - - Comm Err with A/C Communication error with air conditioning amplifier assembly ON / OFF - - Comm Err with Air Bag Communication error with airbag ECU assembly ON / OFF - - Comm Err with Meter Communication error with the combination meter assembly ON / OFF - - Comm Err with Steering Angle Sensor Communication error with spiral cable with sensor sub-assembly ON / OFF - - CPU Duty Status of CPU duty Normal /Abnormal - - EEPROM Malfunction in EEPROM Normal /Abnormal Normal: EEPROM normal - Dec Sensor Calibration Deceleration sensor zero point uncalibrated Comp / Incomp Comp: Deceleration sensor learning completed - Deceleration Sensor Movement Sticking of deceleration sensor Normal / Abnormal Normal: Deceleration sensor not stuck - Neutral Switch Stuck ON Neutral switch stuck on malfunction*1 ON / OFF OFF: System is normal - Oil Pump Abnormal Status of oil pump with motor assembly*1 ON / OFF - - Oil Pump Abnormality Judgment Status of oil pump with motor assembly abnormality judgment*1 Normal / Abnormal - - Status of O/P Signal 1 Status of oil pump with motor assembly signal*1 Normal / Abnormal - - Status of O/P Signal 2 Status of oil pump with motor assembly signal*1 Normal / Abnormal - - Engine Stall Engine stall history No / Yes - - Engine Stall History during S&S (Hood Open) History of engine stall due to the engine hood being opened with shift lever in D while the engine is stopped by stop and start control No / Yes No: No history - Engine Stall History during S&S (Collision or Battery Voltage Low) History of engine stall due to collision or low battery voltage when stop and start control operating No / Yes No: No history - Engine Stall History during Engine Starting (Collision) History of engine stall due to a collision while engine stopped by stop and start control No / Yes No: No history - Engine Start Fail History of engine restart failure while engine stopped by stop and start control No / Yes No: No history - Voltage Judgment Error in voltage judgment Normal / Abnormal - - VB Voltage Low Open in VB circuit No / Yes - - AD Converter Malfunction Malfunction in AD converter ON / OFF - - Starter Delay Circuit Status of starter delay circuit *1 Normal / Abnormal - - Starter Relay Overcurrent Overcurrent in starter relay ON / OFF - - NE Sensor Circuit Open2 Malfunction in crankshaft position sensor circuit ON / OFF OFF: System is normal ON: No engine speed input at engine start. Neutral Switch Stuck OFF Neutral switch stuck off malfunction*1 ON / OFF OFF: System is normal - Brk Boost Malfunc 1 Fail-safe operation due to malfunction of vacuum sensor assembly NG / OK - - Brk Boost Malfunc 2 Fail-safe operation due to malfunction in the vacuum sensor assembly NG / OK - - N Position Voltage Status Malfunction in the neutral position switch*2 Normal/Hi/Low Normal: Neutral position switch voltage normal - Num of Current Code Number of currently stored DTCs Min.: 0, Max.: 255 - - Number of Oper Prohibition (ECM 1) Number of stop and start control prohibitions when ECM conditions are not met Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (ECM 2) Number of stop and start control prohibitions due to SFI system Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Engine F/C) Number of stop and start control prohibitions due to fuel-cut Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Jump Start) Number of stop and start control prohibitions due to jump start Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Engine Hood Closed) Number of stop and start control prohibitions due to open engine hood Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (AT/CVT 1) Number of stop and start control prohibitions due to continuously variable transaxle system condition*1 Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (AT/CVT 2) Number of stop and start control prohibitions due to continuously variable transaxle system condition*1 Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Possible Clutch Lower SW Abnormality) Number of stop and start control prohibitions due to clutch start switch assembly (for lower) malfunction*2 Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Possible Clutch Upper SW Abnormality) Number of stop and start control prohibitions due to clutch start switch assembly (for upper) malfunction*2 Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Neutral SW OFF History) Number of stop and start control prohibitions due to neutral startswitch*2 Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Clutch Upper SW OFF History) Number of stop and start control prohibitions due to clutch start switch assembly (for upper) Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Battery) Number of stop and start control prohibitions due to battery condition Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Start Min Volt) Number of stop and start control prohibitions due to battery condition Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Battery Current) Number of stop and start control prohibitions due to battery condition Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Integrated Current) Number of stop and start control prohibitions due to battery condition Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (A/C) Number of stop and start control prohibitions due to air conditioning condition Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Ambient Temperature) Number of stop and start control prohibitions due to ambient temperature condition Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Ambient Temperature) Number of stop and start control prohibitions due to ambient temperature condition Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (ABS/VSC 1) Number of stop and start control prohibitions due to vehicle stability control system condition*1 Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (ABS/VSC 2) Number of stop and start control prohibitions due to vehicle stability control system condition Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (ABS Running) Number of stop and start control prohibitions due to vehicle stability control system operation Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Panic Brake) Number of stop and start control prohibitions due to sudden braking*1 Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Brake Negative Pressure) Number of stop and start control prohibitions due to brake negative pressure condition Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Stop&Start Precondition1) Number of stop and start control prohibitions due to precondition 1 Min.: 0, Max.: 2147483647 - Condition of permission or prohibition for terms listed below.

(ECM1, ECM2, battery, ABS/ VSC2, IGSW, DTC, A/C, interval, after running, engine hood closed, D door closed, cancel switch, AT/CVT, AT/ CVT2, interval for starter, key operation, driver side buckle SW, ambient temperature)

For details on the preconditions, refer to System Description.

Number of Oper Prohibition (Stop&Start Precondition2) Number of stop and start control prohibitions due to precondition 2 Min.: 0, Max.: 2147483647 - Condition of permission or prohibition for terms listed below.

(Idling, road surface gradient, no shift operation, brake negative pressure, steering, O/P check, starter check complete)

Number of Oper Prohibition (DTC) Number of stop and start control prohibitions due to DTC output Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Abnormal Wheel Speed Sensor Inputs) Number of stop and start control prohibitions due to abnormal vehicle speed signal input Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Deceleration Sensor Abnormal) Number of stop and start control prohibitions due to decelerationsensor malfunction Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Interval For Starter) Number of stop and start control prohibitions due to starter fail-safe operation Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Interval) Number of stop and start control prohibitions due to periodic control prohibition after engine stop Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Cancel Switch) Number of stop and start control prohibitions due to stop and start system cancel switch operation Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Simple-IPA Button) Number of stop and start control prohibitions due to simple-IPA system condition Min.: 0, Max.: 2147483647 - Unused Number of Oper Prohibition (Driver Side Buckle SW) Number of stop and start control prohibitions due to unfastened driver seat belt Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (D Door Closed) Number of stop and start control prohibitions due to open driver door Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (IG SW) Number of stop and start control prohibitions due to ignition or starter switch assembly operation Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (After Running) Number of stop and start control prohibitions based on the initial trip conditions Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Manual Start) Number of stop and start control prohibitions due to manual start condition*2 Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Manual Start during S&S) Number of stop and start control prohibitions due to manual start condition*2 Min.: 0, Max.: 4294967295 - - Number of Oper Prohibition (Idling) Number of stop and start control prohibitions due to idling condition Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Road Surface Gradient) Number of stop and start control prohibitions due to road surface gradient condition Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Steering) Number of stop and start control prohibitions due to power steering system condition Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (No Shift Operation) Number of stop and start control prohibitions based on shift lever position condition*1 Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Key Operation) Number of stop and start control prohibitions due to ignition or starter switch assembly*1 or push start switch assembly*2 operation Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Starter Check Complete) Number of stop and start control prohibitions due to incomplete starter circuit check Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Brake Master Pressure 0 Pt Calib Incomp) Number of stop and start control prohibitions due to incomplete brake master cylinder pressure zeropoint calibration*1 Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (O/P Check) Number of stop and start control prohibitions due to oil pump with motor assembly malfunction Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (Air Suspension) Number of stop and start control prohibitions due to air suspension system condition Min.: 0, Max.: 2147483647 - Unused Number of Oper Prohibition (Welcab) Number of stop and start control prohibitions due to side lift up seat system condition Min.: 0, Max.: 2147483647 - Unused Number of Oper Prohibition (PCS) Number of stop and start control prohibitions due to pre-crash safety system condition*1 Min.: 0, Max.: 2147483647 - - Number of Oper Prohibition (ACC) Number of stop and start control prohibitions due to dynamic radar cruise control system condition*1 Min.: 0, Max.: 2147483647 - - Number of Eng Start Req (ECM) Number of engine start requests from SFI system Min.: 0, Max.: 65535 - - Number of Eng Start Req (Engine Hood Open) Number of engine start requests due to opening of engine hood while engine is stopped by stop and start control Min.: 0, Max.: 65535 - - Number of Eng Start Req (AT/CVT) Number of engine start requests from continuously variable transaxle system*1 Min.: 0, Max.: 65535 - - Number of Eng Start Req (Clutch Lower SW) Number of engine start requests from clutch start switch assembly (for lower)*2 Min.: 0, Max.: 65535 - - Number of Eng Start Req (Battery Condition) Number of engine start requests due to low battery performance Min.: 0, Max.: 65535 - - Number of Eng Start Req (A/C) Number of engine start requests from air conditioning system Min.: 0, Max.: 65535 - - Number of Eng Start Req (ABS/VSC) Number of engine start requests from vehicle stability control system*1 Min.: 0, Max.: 65535 - - Number of Eng Start Req (Brk Negative Pressure Low) Number of engine start requests due to low brake booster vacuum Min.: 0, Max.: 65535 - - Number of Eng Start Req (Detect DTC) Number of engine start requests due to DTC output Min.: 0, Max.: 65535 - - Number of Eng Start Req (CVT Vehicle Speed) Number of engine start requests due to CVT vehicle speed signal input Min.: 0, Max.: 65535 - Unused Number of Eng Start Req (ABS Vehicle Speed) Number of engine start requests due to vehicle stability control system vehicle speed signal input Min.: 0, Max.: 65535 - - Number of Eng Start Req (Cancel SW) Number of engine start requests due to stop and start system cancel switch operation Min.: 0, Max.: 65535 - - Number of Eng Start Req (Simple-IPA) Number of engine start requests from simple-IPA system Min.: 0, Max.: 65535 - Unused Number of Eng Start Req (Courtesy SW or Buckle SW) Number of engine start requests due to driver exiting vehicle Min.: 0, Max.: 65535 - - Number of Eng Start Req (IG Switch) Number of engine start requests due to ignition or starter switch assembly*1 or push start switch assembly*2 operation Min.: 0, Max.: 65535 - - Number of Eng Start Req (Accelerator) Number of engine start requests due to accelerator pedal operation*1 Min.: 0, Max.: 65535 - - Number of Eng Start Req (Steering) Number of engine start requests due to steering operation Min.: 0, Max.: 65535 - - Number of Eng Start Req (Shift Uncert) Number of engine start requests due to uncertain shift lever position*1 Min.: 0, Max.: 65535 - - Number of Eng Start Req (Wrong Shift Lever Operation) Number of engine start requests due to wrong shift lever operation*2 Min.: 0, Max.: 2147483647 - - Number of Eng Start Req (Air Suspension) Number of engine start requests from air suspension system Min.: 0, Max.: 65535 - Unused Number of Eng Start Req (Welcab) Number of engine start requests from side lift up seat system Min.: 0, Max.: 65535 - Unused Number of Eng Start Req (ACC) Number of engine start requests from dynamic radar cruise control system*1 Min.: 0, Max.: 65535 - -

-

*1: for CVT

-

*2: for Manual Transaxle

-

*3: for 2NR-FKE

-

*4: for 1KR-FE

-

*5: for 1ND-TV

- *6: Regarding Battery Integrated Current

In the Stop and start system, the engine stop and start ECU switches the system control mode (Stop and start system control permitted/prohibited) based on the battery condition (charge/discharge condition) to protect the battery and to ensure stable engine restarting performance.

The battery charge-discharge condition is determined from the integrated current value calculated from the battery sensor signal. The integrated current value is obtained by multiplying the current (Ampere) detected by the battery sensor by the time (seconds), and it is expressed in a unit A-sec.

Example: Integrated current of -3110 A-sec corresponds to a load where current of 10 A flows out from the battery for 311 seconds.

The integrated current value can be read by checking the Data List item "Integrated Current" using GTS. The item "Oper permission (Integrated Current)" shows the permission status of Stop and start control (OK or NG) and is judged from the "Integrated Current" value.

Negative integrated current represents battery discharge, and positive represents battery charge. In other words, the "Integrated Current" value of the Data List item will decrease from the present value when the battery is discharged, and the value will increase when the battery is charged.

The engine stop and start ECU determines the amount of power available based on the integrated current value, and it prohibits stop and start control if the value is below the threshold, because the battery might not be able to start the engine. The threshold varies according to the battery temperature.

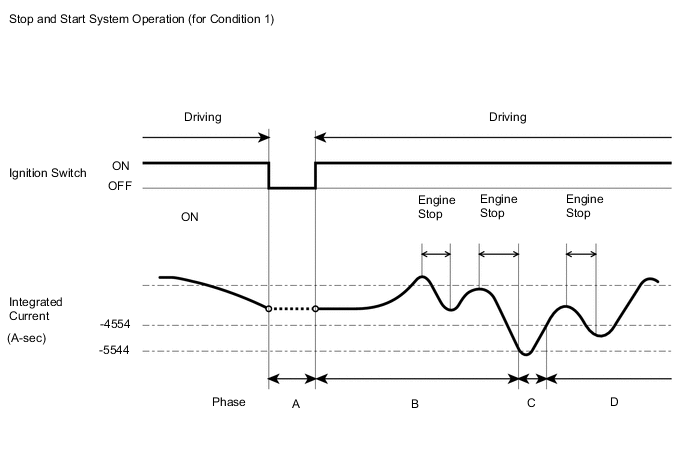

- Integrated Current Condition 1:

-

2NR-FKE (battery type LN3-ISS)

When Status of Battery Charge Control are Charge Control Condition Mode, Stop and Start Standalone Mode or Low Temperature Mode:

-

1ND-TV

When Status of Battery Charge Control are Charge Control Condition Mode or Low Temperature Mode:

-

Phase A (previous trip integrated current storage):

When the ignition switch is turned off, the integrated current value is recorded in the ECU memory. The value is carried over to the next trip.

-

Phase B (stop and start control permitted):

Stop and start control is permitted to stop the engine until the integrated current reaches less than -5544 A-sec.

-

Phase C (charging):

When the integrated current has dropped to less than -5544 A-sec, stop and start control is prohibited from stopping the engine until the current reaches -4554 A-sec.

-

Phase D (stop and start control permitted):

Stop and start control is permitted to stop the engine until the integrated current reaches less than -5544 A-sec.

Stop and Start System Operation (for Condition 1)

-

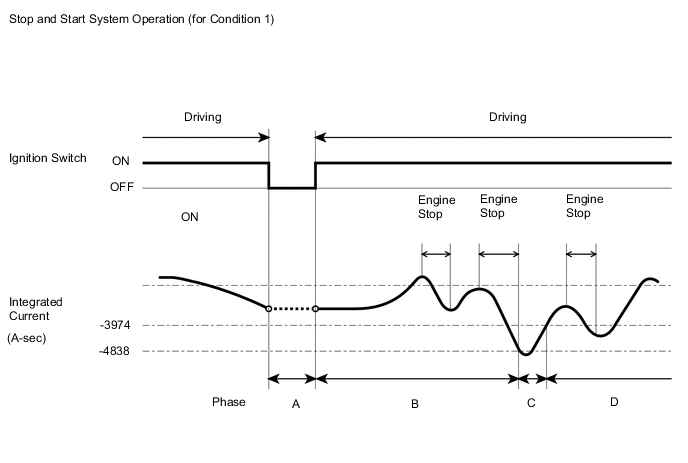

- Integrated Current Condition 1:

-

2NR-FKE (battery type LN2-ISS)

When Status of Battery Charge Control are Charge Control Condition Mode, Stop and Start Standalone Mode or Low Temperature Mode:

-

1KR-FE

When Status of Battery Charge Control are Charge Control Condition Mode or Low Temperature Mode:

-

Phase A (previous trip integrated current storage):

When the ignition switch is turned off, the integrated current value is recorded in the ECU memory. The value is carried over to the next trip.

-

Phase B (stop and start control permitted):

Stop and start control is permitted to stop the engine until the integrated current reaches less than -4838 A-sec.

-

Phase C (charging):

When the integrated current has dropped to less than -4838 A-sec, stop and start control is prohibited from stopping the engine until the current reaches -3974 A-sec.

-

Phase D (stop and start control permitted):

Stop and start control is permitted to stop the engine until the integrated current reaches less than -4838 A-sec.

Stop and Start System Operation (for Condition 1)

-

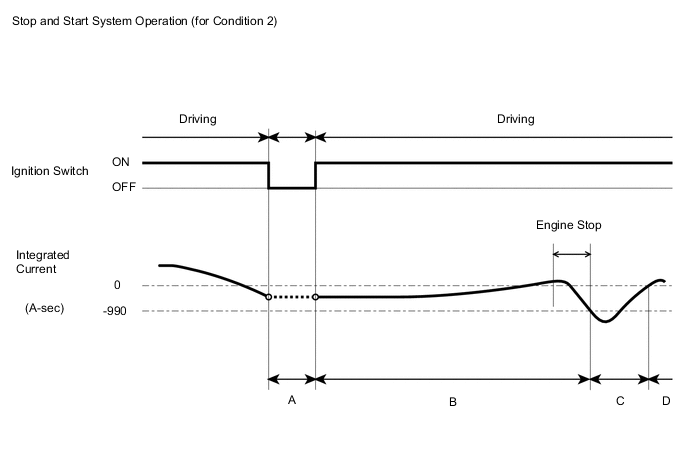

- Integrated Current Condition 2:

-

2NR-FKE (battery type LN3-ISS)

When Status of Battery Charge Control are Stop and Start Restriction Mode or Temperature High/Low Mode:

-

1ND-TV

When Status of Battery Charge Control are Stop and Start Standalone Mode, Stop and Start Restriction Mode or Temperature High/Low Mode:

-

Phase A (previous trip integrated current storage):

When the ignition switch is turned off, the integrated current value is recorded in the ECU memory. The value is carried over to the next trip.

-

Phase B (stop and start control permitted):

Stop and start control is permitted to stop the engine until the integrated current reaches less than -990 A-sec.

-

Phase C (charging):

When the integrated current has dropped to less than -990 A-sec, stop and start control is prohibited from stopping the engine until the current reaches 0 A-sec.

-

Phase D (stop and start control permitted):

Stop and start control is permitted to stop the engine until the integrated current reaches less than -990 A-sec.

Stop and Start System Operation (for Condition 2)

-

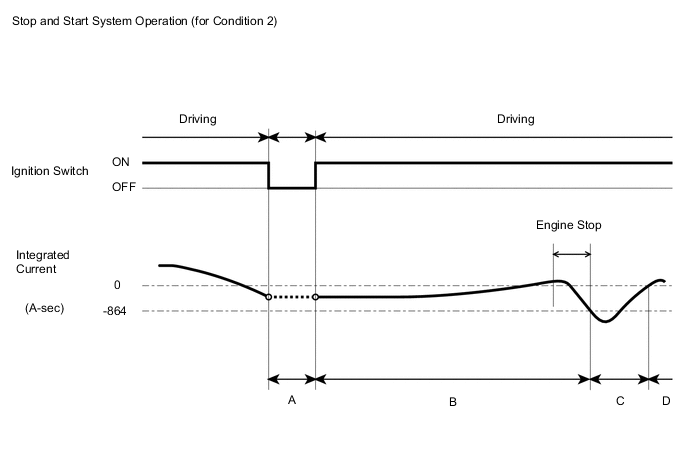

- Integrated Current Condition 2:

-

2NR-FKE (battery type LN2-ISS)

When Status of Battery Charge Control are Stop and Start Restriction Mode or Temperature High/Low Mode:

-

1KR-FE

When Status of Battery Charge Control are Stop and Start Standalone Mode, Stop and Start Restriction Mode or Temperature High/Low Mode:

-

Phase A (previous trip integrated current storage):

When the ignition switch is turned off, the integrated current value is recorded in the ECU memory. The value is carried over to the next trip.

-

Phase B (stop and start control permitted):

Stop and start control is permitted to stop the engine until the integrated current reaches less than -864 A-sec.

-

Phase C (charging):

When the integrated current has dropped to less than -864 A-sec, stop and start control is prohibited from stopping the engine until the current reaches 0 A-sec.

-

Phase D (stop and start control permitted):

Stop and start control is permitted to stop the engine until the integrated current reaches less than -864 A-sec.

Stop and Start System Operation (for Condition 2)

-

Tech Tips

-

Performance (internal resistance) of lead-acid batteries used in typical vehicles changes according to the battery temperature. The internal resistance of the battery tends to be higher when the battery temperature is low. Thus, the stop and start system switches the threshold of charging value according to the battery temperature when performing stop and start control.

-

If the battery is deteriorated, the internal resistance has also increased and the stop and start rate becomes lower. (The total of idling time while the vehicle is stopped increases.)

-

When troubleshooting, if the malfunction cannot be identified, the battery might be deteriorated.

-

-

ACTIVE TEST

Tech Tips

Using the GTS to perform Active Tests allows relays, actuators and other items to be operated without removing any parts. This non-intrusive functional inspection can be very useful because intermittent operation may be discovered before parts or wiring is disturbed. Performing Active Tests early in troubleshooting is one way to save diagnostic time. Data List information can be displayed while performing Active Tests.

-

Connect the GTS to the DLC3.

-

Start the engine.

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Stop and Start / Active Test.

-

Perform the Active Test by referring to the table below.

Stop and Start System Tester Display Test Part Control Range Diagnostic Note Buzzer Buzzer activation ON/OFF - Starter Starter activation ON/OFF Note

-

Maximum activation time is 3 seconds

-

After activation, operation is prohibited for 3 seconds

Pinion Gear Plunger*1 Pinion activation ON/OFF Note

-

Maximum activation time is 3 seconds

-

After activation, operation is prohibited for 3 seconds

Starter Motor Drive Magnet Switch*1 Starter motor activation ON/OFF Note

-

Maximum activation time is 3 seconds

-

After activation, operation is prohibited for 3 seconds

Permit Cond (A/C) A/C ON/OFF - Permit Cond (Battery) Battery ON/OFF - Permit Cond (Engine) Engine ON/OFF - Permit Cond (ABS)*1 ABS/VSC ON/OFF - AT Oil Pump (Hi)*1 AT oil pump activation ON/OFF HI activation AT Oil Pump (Lo)*1 AT oil pump activation ON/OFF LO activation Precondition (Control) Precondition (Control) activation ON/OFF Condition of permission or prohibition for terms listed below.

(ECM1, ECM2, idling, battery, ABS/VSC, ABS/VSC2, IGSW, DTC, A/C, interval, after running, engine hood closed, D door closed, cancel switch, interval for starter, key operation, AT/CVT, AT/CVT2, driver side buckle SW, ambient temperature)

Precondition2 (Control) Precondition2 (Control) activation ON/OFF Condition of permission or prohibition for terms listed below.

(idling, brake negative pressure, steering, road surface gradient, no shift operation, O/P check, starter check complete)

Start Cond (Hood Crtsy) Engine hood ON/OFF -

-

*1: for CVT

Tech Tips

Even if Stop and start system control is prohibited due to the condition of any of the systems listed above, performing the Active Tests allows Stop and start system control to be performed.

-