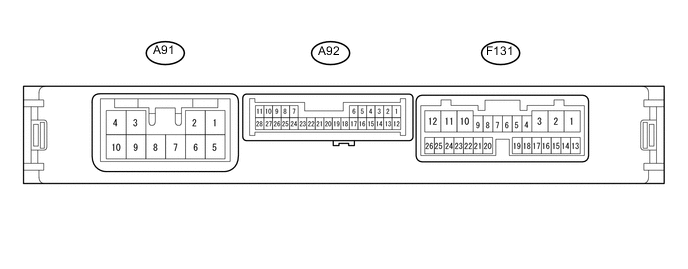

STOP AND START SYSTEM TERMINALS OF ECU

-

ENGINE STOP AND START ECU

-

Disconnect the A91, A92 and F131 engine stop and start ECU connectors.

-

Measure the resistance and voltage according to the value(s) in the table below.

Terminal No.

(Symbol)

Wiring Color Terminal Description Condition Specified Condition A91-5 (+B) - Body ground B - Body ground Power source of engine stop and start ECU Ignition switch ON 9.5 to 14 V A91-7 (BIN) - Body ground B - Body ground Battery Always 9.5 to 14 V A91-8 (GND) - Body ground W-B - Body ground Ground Always Below 1 Ω A92-10 (NE) - Body ground V - Body ground Engine speed signal from ECM Always 10 kΩ or higher A92-17 (VB-) - Body ground W-B - Body ground Ground Always Below 1 Ω F131-15 (CANH) - Body ground BE - Body ground CAN communication Always 10 kΩ or higher F131-16 (CANL) - Body ground W - Body ground CAN communication Always 10 kΩ or higher F131-17 (IG1) - Body ground L - Body ground Ignition switch signal Ignition switch ON 9.5 to 14 V F131-19 (ACC) - Body ground L - Body ground Ignition switch signal Ignition switch ACC 9.5 to 14 V F131-20 (IG2) - Body ground P - Body ground Ignition switch signal Ignition switch ON 9.5 to 14 V -

Reconnect the A91, A92 and F131 engine stop and start ECU connectors.

-

Measure the resistance, voltage and check for pulse according to the value(s) in the table below.

Terminal No.

(Symbol)

Wiring Color Terminal Description Condition Specified Condition A91-6 (OPO)*1 - A91-8 (GND) SB - W-B Oil pump with motor assembly (continuously variable transaxle assembly) drive power source signal When the engine is stopped by stop and start control system, or when performing the AT Oil Pump Lo Drive of the Active Test 10 to 14 V A92-3 (BRE2) - Body ground R - Body ground Ground (vacuum sensor assembly (brake booster pressure sensor)) Always Below 1 Ω A92-7 (BNT1) - A91-8 (GND) P - W-B Engine hood courtesy switch (hood lock assembly) signal

-

Ignition switch ON

-

Engine stopped

-

Engine hood closed

0 to 1.5 V

-

Ignition switch ON

-

Engine stopped

-

Engine hood open

8 to 14 V A91-9 (OPM1)*1 - A91-8 (GND) P - W-B Oil pump with motor assembly (continuously variable transaxle assembly) drive power source signal When the engine is stopped by stop and start control system, or when performing the AT Oil Pump Lo Drive of the Active Test Pulse generation

(see waveform 1)

A92-10 (NE) - A91-8 (GND) V - W-B Engine speed signal from ECM Idling after engine warmed up Pulse generation

(see waveform 2)

A92-11 (CLU)*2- A91-8 (GND) B - W-B Clutch start switch assembly (for upper) signal

-

Ignition switch ON

-

Clutch pedal released

8 to 14 V

-

Ignition switch ON

-

Clutch pedal fully depressed

Below 1.5 V A92-13 (PB) - A92-3 (BRE2) LG - R Vacuum sensor assembly (brake booster pressure sensor) signal

-

Ignition switch ON

-

Absolute pressure of 40 kPa (0.4 kgf/cm2, 5.8 psi) applied to vacuum sensor assembly (brake booster pressure sensor)

1.6 to 2.0 V

-

Ignition switch ON

-

Absolute pressure of 60 kPa (0.6 kgf/cm2, 8.7 psi) applied to vacuum sensor assembly (brake booster pressure sensor)

2.2 to 2.6 V

-

Ignition switch ON

-

Atmospheric pressure applied to vacuum sensor assembly (brake booster pressure sensor)

3.4 to 3.8 V A92-14 (BRVC) - A91-8 (GND) G - W-B Vacuum sensor assembly (brake booster pressure sensor) power supply

-

Ignition switch ON

-

Engine stopped

4.5 to 5.5 V A92-21 (STA) - A91-8 (GND) P - W-B Starter pinion activation signal Cranking 6.0 V or more A92-23*1 (STA2) - A91-8 (GND) W - W-B Starter motor activation signal Cranking 6.0 V or more A92-26 (TMVC)*2 - A91-8 (GND) B - W-B Neutral position switch power supply

-

Ignition switch ON

-

Engine stopped

4.5 to 5.5 V A92-27 (TMN)*2- A91-25 (TME2)*2 W - P Neutral position switch signal

-

Ignition switch ON

-

Shift lever in neutral

2.7 to 4.3 V

-

Ignition switch ON

-

Shift lever in any other than neutral

0.7 to 1.9 V A92-27 (OPST)*1 - A91-8 (GND) V - W-B Oil pump with motor assembly (continuously variable transaxle assembly) drive power source signal Idling after engine warmed up 10 to 14 V When the engine is stopped by stop and start control system, or when performing the AT Oil Pump Lo Drive of the Active Test Pulse generation

(see waveform 3)

A92-28 (CLL) - A91-8 (GND) R - W-B Park/neutral position switch signal*1

-

Ignition switch ON

-

Shift lever in any other than N or P

8 to 14 V

-

Ignition switch ON

-

Shift lever in N or P

Below 3.0 V Clutch start switch assembly (for lower) signal*2

-

Ignition switch ON

-

Clutch pedal released

8 to 14 V

-

Ignition switch ON

-

Clutch pedal fully depressed

Below 1.5 V F131-2 (BO1) - A91-8 (GND) SB - W-B Backup boost converter signal Always 9.5 to 14 V F131-3 (ACO) - A91-8 (GND) GR - W-B Backup boost converter signal Ignition switch ACC 9.5 to 14 V F131-11 (IGO2) - A91-8 (GND) P - W-B Backup boost converter signal Ignition switch ON 9.5 to 14 V F131-12 (IGO1) - A91-8 (GND) B - W-B Backup boost converter signal Ignition switch ON 9.5 to 14 V F131-17 (IG1) - A91-8 (GND) L - W-B Ignition switch signal Ignition switch ACC Below 1 V Ignition switch ON 9.5 to 14 V F131-19 (ACC) - A91-8 (GND) L - W-B Ignition switch signal Ignition switch off Below 1 V Ignition switch ACC 9.5 to 14 V F131-20 (IG2) - A91-8 (GND) P - W-B Ignition switch signal Ignition switch ACC Below 1 V Ignition switch ON 9.5 to 14 V F131-23 (ECAN) - A91-8 (GND) SB - W-B Stop and start cancel switch (warning canceling switch assembly) signal

-

Ignition switch ON

-

Stop and start cancel switch (warning canceling switch assembly) pressed

0 to 1.5 V

-

Ignition switch ON

-

Stop and start cancel switch (warning canceling switch assembly) not pressed

8 to 14 V

-

*1: for CVT

-

*2: for Manual Transaxle

-

-

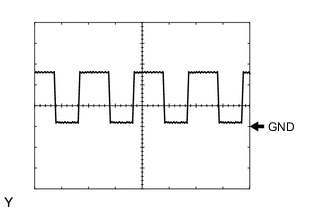

Waveform 1

Oil Pump Assembly with Motor (Continuously Variable Transaxle Assembly) Directions Signal Item Content Tester connection OPM1 - GND Tool setting 5 V/DIV., 5 ms./DIV. Condition When the engine is stopped by stop and start control system, or when performing the AT Oil Pump Lo Drive of the Active Test. -

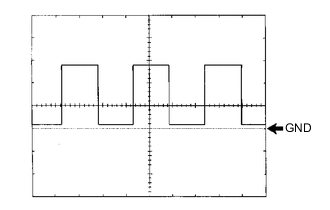

Waveform 2

Engine Speed Signal Item Content Tester connection NE - GND Tool setting 5 V/DIV., 5 ms./DIV. Condition Idling after engine warmed up Tech Tips

The wavelength become shorter as the engine speed increases.

-

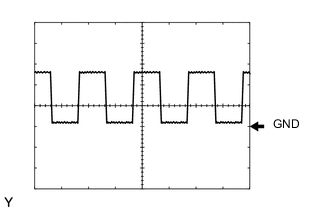

Waveform 3

Oil Pump Assembly with Motor (Continuously Variable Transaxle Assembly) Speed Signal Item Content Tester connection OPST - GND Tool setting 5 V/DIV., 5 ms./DIV. Condition When the engine is stopped by stop and start control system, or when performing the AT Oil Pump Lo Drive of the Active Test.

-