PROCEDURE

-

Click here

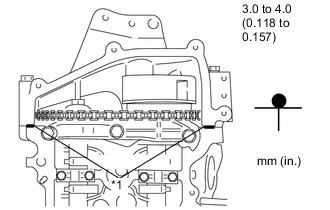

INSTALL CYLINDER BLOCK WATER JACKET SPACER (w/ Cylinder Block Water Jacket Spacer)

-

Install the cylinder block water jacket spacer to the cylinder head.

Table 1. Text in Illustration *a Engine Front Side

-

- Click here

INSTALL CYLINDER HEAD GASKET

- Click here

INSTALL CYLINDER HEAD SUB-ASSEMBLY

Note:Place the cylinder head gently in order not to damage the gasket.

-

Place the cylinder head on the cylinder block.

-

Install the 8 plate washers to the cylinder head subassembly.

Note:Do not drop the washers into the cylinder head.

-

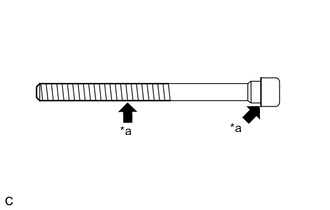

Apply engine oil to each bolt thread and seating surface.

Table 2. Text in Illustration *a Apply Engine Oil -

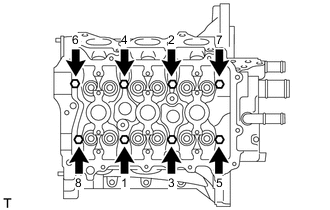

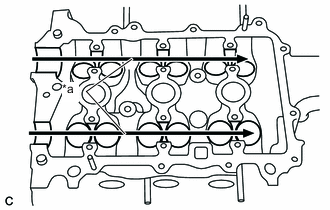

Using several passes, uniformly install and tighten the 8 cylinder head bolts with an 8 mm bi-hexagon wrench in the order shown in the illustration.

32 N*m 326 kgf*cm 24 ft.*lbf -

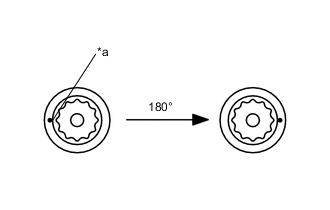

Mark the front of each cylinder head bolt with paint.

Table 3. Text in Illustration *a Paint Mark -

Retighten the cylinder head bolts by additional 180° as shown in the illustration.

-

Check that the painted marks are now 180° from the front.

-

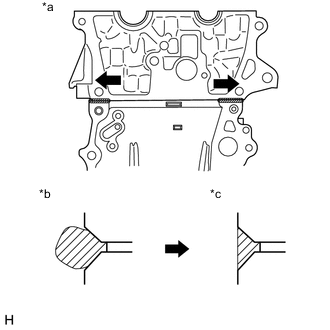

After tightening the cylinder head bolts, wipe off the seal packing material that seeped out from the contact surface between the cylinder head and cylinder block.

Table 4. Text in Illustration *a Direction to wipe off *b Before wiping off *c After wiping off Note:

-

Be sure to wipe off the seal packing from inside to outside, parallel to the joint line.

-

Be sure to avoid clogging the bolt holes when wiping off the seal packing.

-

-

- Click here

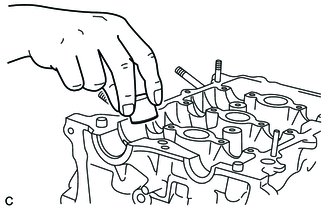

INSTALL VALVE LIFTER

-

Apply engine oil to the circumference of the valve lifters.

-

Install the valve lifters straight into the lifter holes.

Note:Check that the valve lifters turn smoothly after installing them.

-

-

Click here

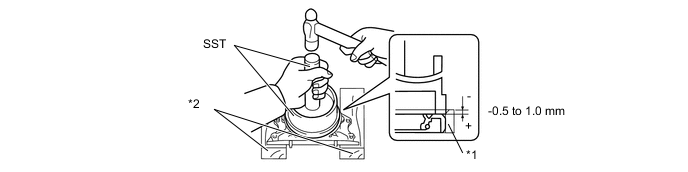

INSTALL ENGINE REAR OIL SEAL

-

Apply engine oil to the lip of a new oil seal.

Table 5. Text in Illustration

Apply Engine Oil -

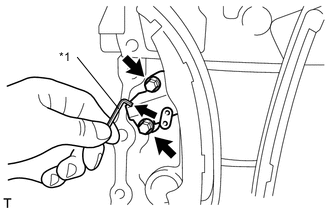

Using SST, tap the oil seal straight in.

Table 6. Text in Illustration *1 Rear Oil Seal Retainer *2 Wooden Block 09223-15020 09950-70010 09951-07200 Standard depth -1.0 to 0.5 mm (-0.0394 to 0.0197 in.) Note:

-

Keep the lip free from foreign materials.

-

Do not tap on the oil seal at an angle.

-

-

-

Click here

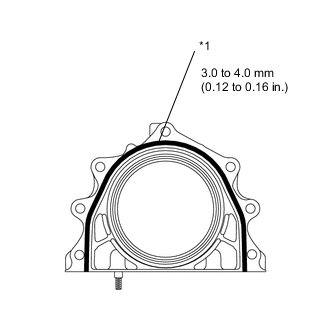

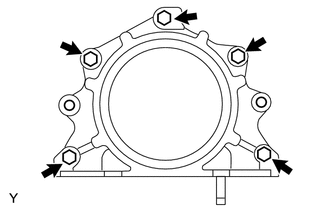

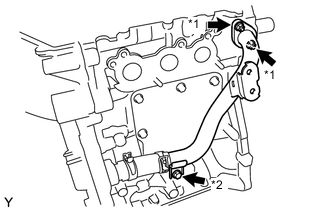

INSTALL ENGINE REAR OIL SEAL RETAINER

-

Install the stud bolt to the rear oil seal retainer.

-

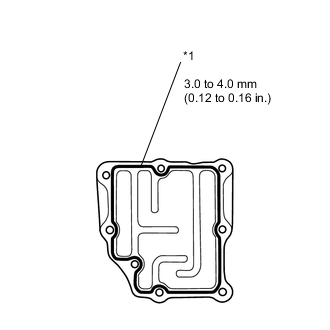

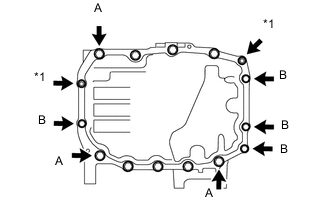

Apply a continuous bead of seal packing as shown in the illustration.

Table 7. Text in Illustration *1 Seal Packing Seal packing Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent -

Install the oil seal retainer with the 5 bolts.

10 N*m 102 kgf*cm 7 ft.*lbf Note:

-

Install the oil seal retainer within 3 minutes and tighten the bolts within 15 minutes after applying seal packing.

-

Do not add engine oil for at least 2 hours after installation.

-

Do not start the engine for at least 2 hours after installation.

-

-

- Click here

INSTALL VENTILATION BAFFLE PLATE

-

Clean the installation surface of the cylinder block and ventilation baffle plate.

-

Apply a continuous bead of seal packing as shown in the illustration.

Table 8. Text in Illustration *1 Seal Packing Seal packing Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent -

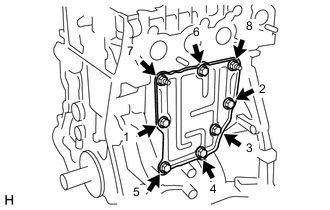

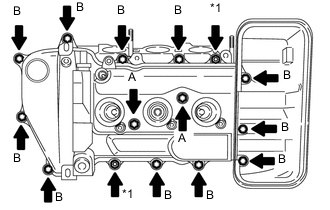

Install the ventilation baffle plate in the order shown in the illustration with the 6 bolts and 2 nuts.

24 N*m 245 kgf*cm 18 ft.*lbf Note:Install the ventilation baffle plate within 3 minutes and tighten the bolts within 15 minutes after applying seal packing.

-

-

Click here

INSTALL CAMSHAFTS

-

Before installing the camshaft, turn the crankshaft approximately 90° in the engine revolution direction from the point where the No. 1 piston is set at the TDC so that the lifted valve and piston do not touch each other.

-

Apply engine oil to the contact areas of the cam and journal of the camshaft and No. 2 camshaft.

Table 9. Text in Illustration *a Apply Engine Oil -

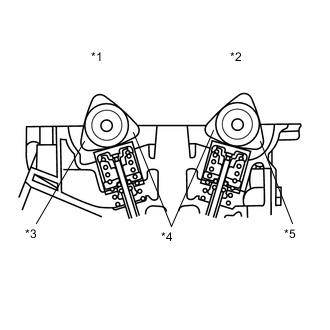

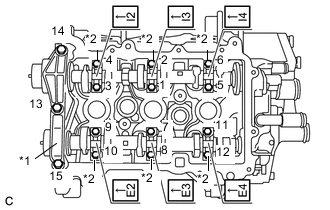

Install the camshafts as shown in the illustration.

Table 10. Text in Illustration *1 No. 1 Camshaft *2 No. 2 Camshaft *3 No. 3 Cylinder *4 No. 1 Cylinder *5 No. 2 Cylinder -

Set the No. 1 camshaft bearing cap and No. 2 camshaft bearing caps and tighten the bolts in the order shown in the illustration.

Table 11. Text in Illustration *1 No. 1 Camshaft Bearing Cap *2 No. 2 Camshaft Bearing Cap No. 1 Camshaft bearing cap 15 N*m 153 kgf*cm 11 ft.*lbf No. 2 Camshaft bearing cap 13 N*m 127 kgf*cm 9 ft.*lbf Note:

-

Install the bearing caps with the front marks facing the engine front.

-

Install the bolts in the correct positions by referring to the numbers inscribed on the bolts and the table below.

Table 12. Installation position of the No. 2 bearing cap Installation position Inscribed No. Intake No. 1 cylinder I2 Intake No. 2 cylinder I3 Intake No. 3 cylinder I4 Exhaust No. 1 cylinder E2 Exhaust No. 2 cylinder E3 Exhaust No. 3 cylinder E4 -

-

- Click here

INSTALL CAMSHAFT TIMING GEAR

-

Insert the camshaft timing gear so that the knock pin on the No. 2 camshaft end fits into the groove.

-

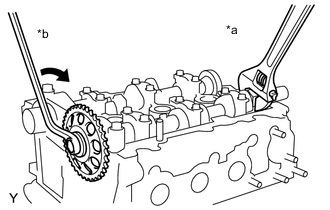

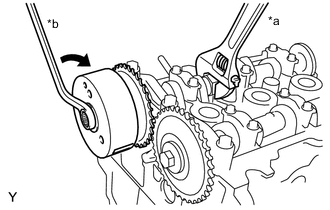

While holding the hexagonal portion of the No. 2 camshaft, tighten the bolts to install the camshaft timing gear.

Table 13. Text in Illustration *a Hold *b Turn 47 N*m 479 kgf*cm 35 ft.*lbf

-

- Click here

INSTALL CAMSHAFT TIMING SPROCKET ASSEMBLY

-

Apply engine oil to the camshaft timing sprocket installation portion of the camshaft.

-

Insert the knock pin on the camshaft end into the knock hole in the camshaft timing sprocket.

Note:

-

Slightly turn the sprocket to make sure that the knock pin is securely installed after inserting the knock pin.

-

The end surface of the sprocket may be damaged if the sprocket is turned with excessive force when the knock pin is not inserted.

-

-

While holding the hexagonal portion of the camshaft, tighten the bolts to install the camshaft timing sprocket.

Table 14. Text in Illustration *a Hold *b Turn 47 N*m 479 kgf*cm 35 ft.*lbf

-

- Click here

INSPECT VALVE CLEARANCE

- Click here

ADJUST VALVE CLEARANCE

-

Click here

INSTALL CRANKSHAFT STRAIGHT PIN

-

Install the crankshaft straight pin to the crankshaft groove.

-

-

Click here

INSTALL CRANKSHAFT TIMING SPROCKET

-

Align the groove of the crankshaft timing sprocket with the key of the crankshaft and install the crankshaft timing sprocket.

-

-

Click here

INSTALL TIMING CHAIN GUIDE

-

Install the timing chain guide with the 2 bolts.

9.0 N*m 92 kgf*cm 80 in.*lbf

-

-

Click here

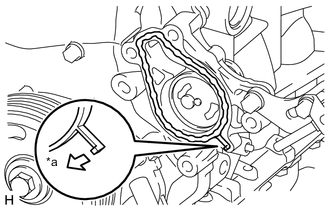

INSTALL CHAIN SUB-ASSEMBLY

-

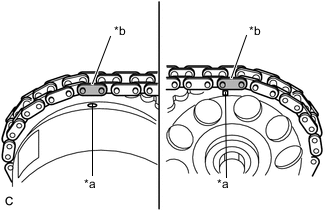

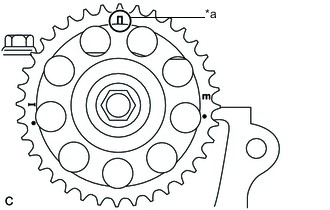

Align the yellow mark plate with the timing mark of the crankshaft timing sprocket and install the timing chain, as shown in the illustration.

Table 15. Text in Illustration *a Yellow Mark Plate *b Timing Mark -

Align the 2 orange mark plates with the timing marks of the camshaft timing sprockets and install the timing chain, as shown in the illustration.

Table 16. Text in Illustration *a Timing Mark *b Orange Mark Plate

-

-

Click here

INSTALL TIMING CHAIN TENSION ARM

-

Install the timing chain tension arm with the bolt.

19 N*m 194 kgf*cm 14 ft.*lbf

-

-

Click here

INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY

-

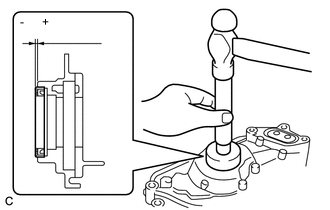

Slightly turn the hexagonal portion of the camshaft assembly (intake side) counterclockwise to leave some slack on the chain of the timing chain tensioner side.

-

Install the chain tensioner with the 2 bolts.

Table 17. Text in Illustration *1 Hexagon Wrench 11 N*m 107 kgf*cm 8 ft.*lbf -

Remove the hexagon wrench, turn the crankshaft 2 complete revolutions and operate the chain tension.

-

Make sure that the timing mark of the sprocket camshaft timing is at the top with the timing chain tensed (set No. 1 piston to the TDC/exhaust).

Table 18. Text in Illustration *a Timing Mark

-

-

Click here

INSTALL TIMING CHAIN COVER OIL SEAL

-

Apply engine oil to the lip of a new oil seal.

Table 19. Text in Illustration *a Engine oil -

Using SST, tap the oil seal straight in.

09950-60010 09951-00500 09952-06010 09950-70010 09951-07200 Standard depth -1.0 to 0.5 mm (-0.0394 to 0.0197 in.) Note:Do not tap the oil seal at an angle.

-

- Click here

INSTALL STUD BOLT (for TMC Made)

-

Apply adhesive to 2 or 3 threads (chain cover side) of the 2 stud bolts.

Adhesive Toyota Genuine Adhesive 1324, Three Bond 1344 or equivalent -

Install the 2 stud bolts to the timing chain cover.

-

- Click here

INSTALL STUD BOLT (for TMMF Made)

-

Apply adhesive to 2 or 3 threads (chain cover side) of the stud bolt.

Adhesive Toyota Genuine Adhesive 1324, Three Bond 1344 or equivalent -

Install the stud bolt to the timing chain cover.

-

- Click here

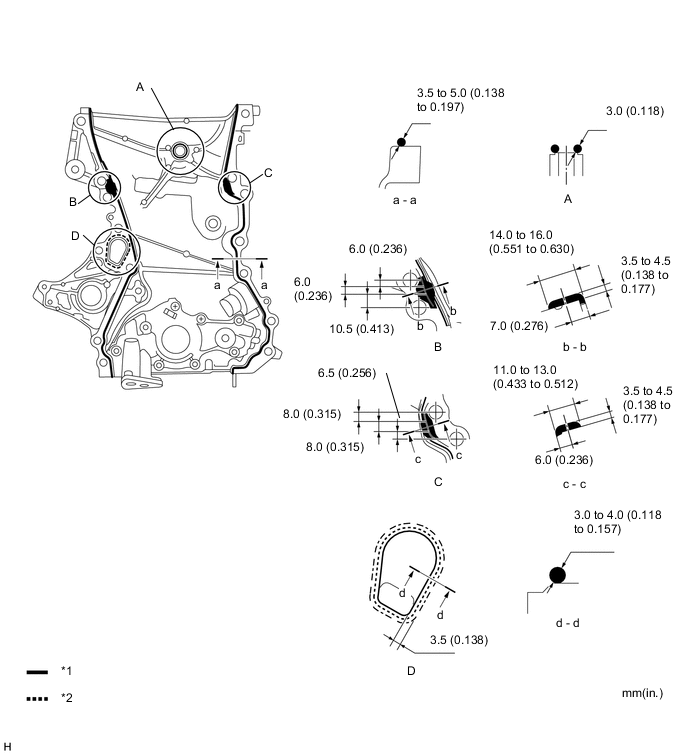

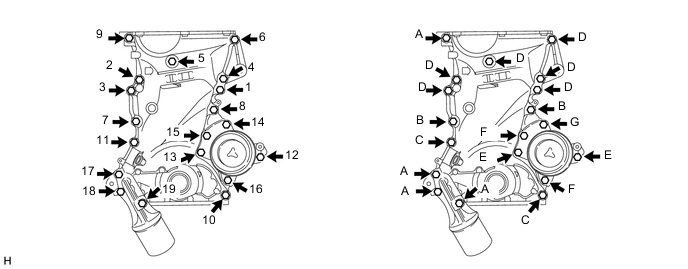

INSTALL TIMING CHAIN COVER SUB-ASSEMBLY

-

Remove any old packing material remaining on the sealing surfaces before applying seal packing.

-

Clean and degrease the contact surfaces of the timing chain cover, cylinder head, cylinder block and confirm that no oil, moisture, or other foreign matter remains on the surfaces.

-

Install a new oil pump gasket to the cylinder block.

-

Apply seal packing to the timing chain cover as shown in the following illustration.

Table 20. Text in Illustration *1 Toyota Genuine Seal Packing Black, Three Bond 1207B *2 Toyota Genuine Seal Packing 1282B, Three Bond 1282B Seal packing Water pump part Toyota Genuine Seal Packing 1282B, Three Bond 1282B or equivalent Other part Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Note:

-

Install the chain cover within 3 minutes and tighten the bolts within 10 minutes after applying seal packing.

-

Do not start the engine for at least 2 hours after installing.

-

-

Temporarily install the timing chain cover with the 11 bolts.

Bolt Length Item Length Bolt A 80 mm (3.150 in.) Bolt B 40 mm (1.575 in.) Bolt C

(with washer)

45 mm (1.772 in.) Bolt D 70 mm (2.756 in.) -

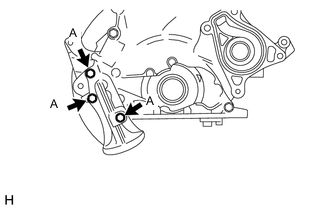

Install a new oil filter bracket gasket to the timing chain cover.

-

Temporarily install the oil filter bracket with the 3 bolts.

Bolt Length Item Length Bolt A 80 mm (3.150 in.) -

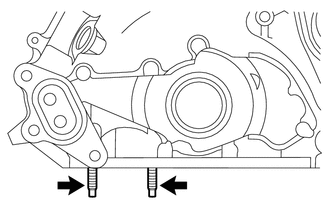

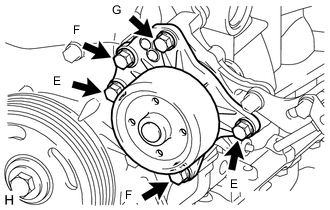

Install a new water pump gasket to the timing chain cover as shown in the illustration.

Table 21. Text in Illustration *a Water Pump Side -

Temporarily install the water pump with the 5 bolts.

Bolt Length Item Length Bolt E 20 mm (0.787 in.) Bolt F 50 mm (1.969 in.) Bolt G 45 mm (1.772 in.) -

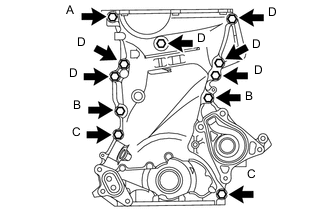

Fully tighten the timing chain cover with the 19 bolts in the order shown in the illustration.

Bolt A, C 24 N*m 245 kgf*cm 18 ft.*lbf Bolt B, D 40 N*m 408 kgf*cm 30 ft.*lbf Bolt E, F, G 28 N*m 286 kgf*cm 21 ft.*lbf Bolt Length Item Length Bolt A 80 mm (3.150 in.) Bolt B 40 mm (1.575 in.) Bolt C

(with washer)

45 mm (1.772 in.) Bolt D 70 mm (2.756 in.) Bolt E 20 mm (0.787 in.) Bolt F 50 mm (1.969 in.) Bolt G 45 mm (1.772 in.) -

Wipe off the excess seal packing.

-

- Click here

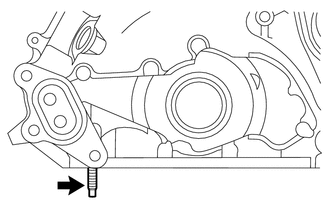

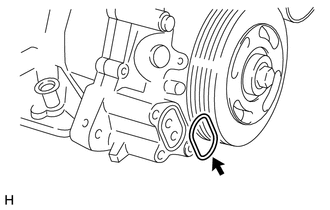

INSTALL DRAIN PLUG

-

Install the drain plug with a new gasket.

54 N*m 551 kgf*cm 40 ft.*lbf

-

-

Click here

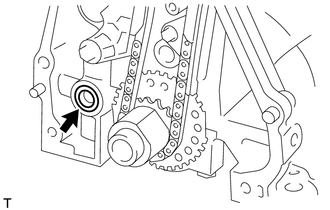

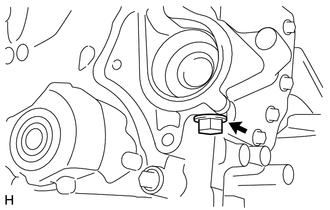

INSTALL TIGHT PLUG

-

Clean the plug and the bolt holes of the timing chain cover and apply adhesive to the threads of the tight plug.

Table 22. Text in Illustration *1 Adhesive Adhesive Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent -

Using an 8 mm socket hexagon wrench, install the tight plug.

Table 23. Text in Illustration *1 8 mm Socket Hexagon Wrench 15 N*m 153 kgf*cm 11 ft.*lbf Note:Do not start the engine for at least 1 hour after installing.

-

-

Click here

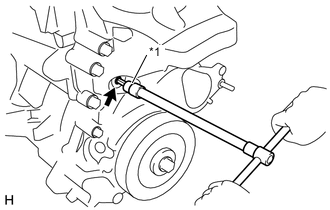

INSTALL CRANKSHAFT PULLEY

-

Align the pulley set key with the key groove of the crankshaft pulley, and then slide on the crankshaft pulley.

-

Using SST, install the crankshaft pulley bolt.

Table 24. Text in Illustration *a Hold *b Turn 09960-10010 09962-01000 09963-01000 180 N*m 1835 kgf*cm 133 ft.*lbf

-

-

Click here

INSTALL OIL FILTER SUB-ASSEMBLY

-

Check and clean the oil filter installation surface.

-

Apply clean engine oil to the gasket of a new oil filter.

-

Gently screw the oil filter into place, then tighten it until the gasket comes into contact with the seat.

-

Using SST, tighten the oil filter.

09228-06501 10 N*m 102 kgf*cm 7 ft.*lbf

-

-

Click here

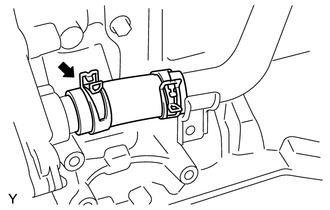

INSTALL WATER BY-PASS HOSE

-

Install the water by-pass hose to the No. 1 water by-pass pipe.

-

-

Click here

INSTALL NO. 1 WATER BY-PASS PIPE

-

Install a new water by-pass pipe gasket to the cylinder head as shown in the illustration.

Table 25. Text in Illustration *a Water By-pass Side -

Connect the water by-pass hose to the timing chain cover.

-

Temporarily install the water by-pass pipe with the bolt and 2 nuts.

Table 26. Text in Illustration *1 Nut *2 Bolt -

Fully tighten the 2 nuts.

24 N*m 245 kgf*cm 18 ft.*lbf -

Fully tighten the bolt.

24 N*m 245 kgf*cm 18 ft.*lbf

-

-

Click here

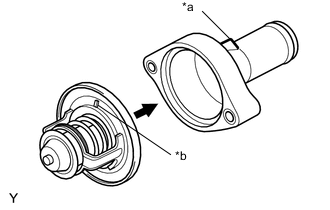

INSTALL THERMOSTAT

-

Install a new water outlet gasket to the thermostat.

-

Install the thermostat to the water inlet with the jiggle pin facing straight upward.

Table 27. Text in Illustration *a Upper Indication *b Jiggle Pin

-

-

Click here

INSTALL WATER INLET

-

Install the water inlet with the 2 bolts.

7.0 N*m 71 kgf*cm 62 in.*lbf Note:

-

Avoid catching the rubber gasket of thermostat under the water inlet.

-

Do not use a water inlet that has been dropped.

-

Ensure that gasket is secured between the water inlet and block.

-

-

- Click here

INSTALL OIL STRAINER SUB-ASSEMBLY

-

Install a new oil strainer gasket to the oil strainer.

-

Install the oil strainer to the timing chain cover with the 3 bolts.

8.5 N*m 87 kgf*cm 75 in.*lbf

-

- Click here

INSTALL OIL PAN SUB-ASSEMBLY (for TMC Made)

-

Remove any old packing material remaining on the sealing surfaces before applying seal packing.

-

Clean and degrease the contact surfaces of the oil pan, cylinder block and confirm that no oil, moisture, or other foreign matter remains on the surfaces.

-

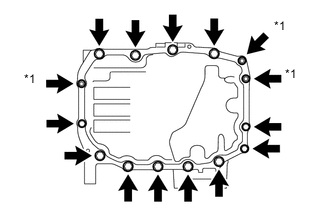

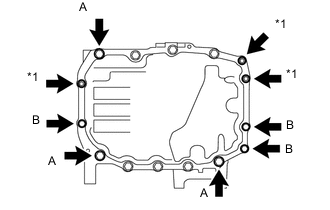

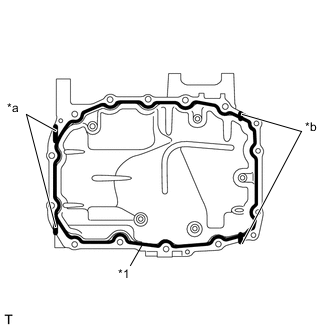

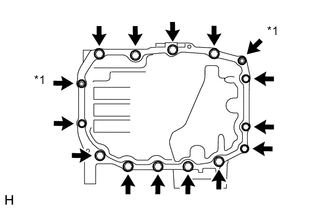

Apply seal packing to the oil pan as shown in the following illustration.

Table 28. Text in Illustration *1 Toyota Genuine Seal Packing Black, Three Bond 1207B *a Contact surface between timing chain cover and cylinder block *b Contact surface between oil seal retainer and cylinder block Seal packing Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Note:

-

Start and finish applying the seal packing on the seal surface with the cylinder block subassembly.

-

Apply seal packing to the contact surfaces between the timing chain cover and cylinder block, and between the oil seal retainer and cylinder block.

-

Install the oil pan sub-assembly within 3 minutes and tighten the bolts within 15 minutes of applying seal packing.

-

-

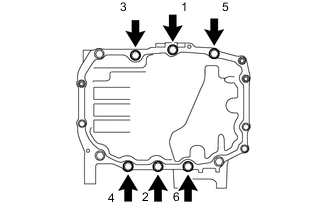

Temporarily install the oil pan with the 12 bolts and 3 nuts.

Table 29. Text in Illustration *1 Nut -

Fully tighten the 6 bolts in the order shown in the illustration.

24 N*m 245 kgf*cm 18 ft.*lbf -

Fully tighten the 6 bolts and 3 nuts.

Table 30. Text in Illustration *1 Nut Bolt A 24 N*m 245 kgf*cm 18 ft.*lbf Bolt B, Nut 10 N*m 102 kgf*cm 7 ft.*lbf

-

- Click here

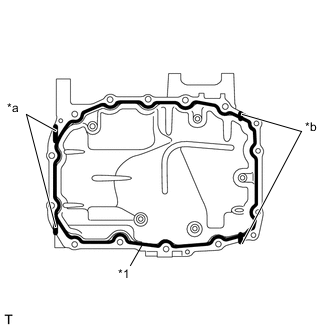

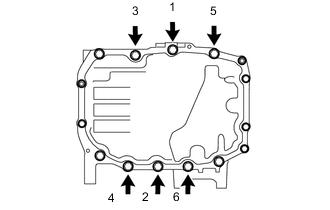

INSTALL OIL PAN SUB-ASSEMBLY (for TMMF Made)

-

Remove any old packing material remaining on the sealing surfaces before applying seal packing.

-

Clean and degrease the contact surfaces of the oil pan, cylinder block and confirm that no oil, moisture, or other foreign matter remains on the surfaces.

-

Apply seal packing to the oil pan as shown in the following illustration.

Table 31. Text in Illustration *1 Toyota Genuine Seal Packing Black, Three Bond 1207B *a Contact surface between timing chain cover and cylinder block *b Contact surface between oil seal retainer and cylinder block Seal packing Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Note:

-

Start and finish applying the seal packing on the seal surface with the cylinder block subassembly.

-

Apply seal packing to the contact surfaces between the timing chain cover and cylinder block, and between the oil seal retainer and cylinder block.

-

Install the oil pan sub-assembly within 3 minutes and tighten the bolts within 15 minutes of applying seal packing.

-

-

Temporarily install the oil pan with the 13 bolts and 2 nuts.

Table 32. Text in Illustration *1 Nut -

Fully tighten the 6 bolts in the order shown in the illustration.

24 N*m 245 kgf*cm 18 ft.*lbf -

Fully tighten the 7 bolts and 2 nuts.

Table 33. Text in Illustration *1 Nut Bolt A 24 N*m 245 kgf*cm 18 ft.*lbf Bolt B, Nut 10 N*m 102 kgf*cm 7 ft.*lbf

-

-

Click here

INSTALL OIL PAN DRAIN PLUG

-

Install the engine oil drain plug with a new oil pan drain plug gasket.

30 N*m 301 kgf*cm 22 ft.*lbf

-

-

Click here

INSTALL VENTILATION VALVE SUB-ASSEMBLY

-

Install a new grommet, as shown in the illustration.

Table 34. Text in Illustration *1 Ventilation Valve *2 Grommet -

Install the ventilation valve.

-

- Click here

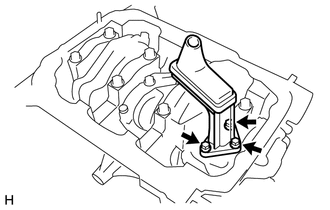

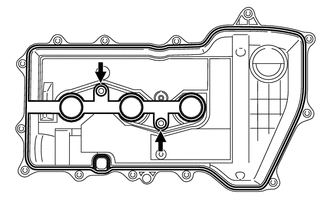

INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY

-

Clean the cylinder head cover, cylinder head assembly and timing chain cover.

-

Install a new cylinder head cover gasket into the groove on the cylinder head cover and onto the center bosses.

Note:Insert the gasket securely until it completely fits into the bosses.

-

Apply a continuous bead of seal packing to the contact surface between the cylinder head assembly and timing chain cover assembly, as shown in the illustration.

Table 35. Text in Illustration *1 Seal Packing Seal packing Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Note:Install the chain cover within 3 minutes and tighten the bolts within 15 minutes after applying seal packing.

-

Temporarily install the cylinder head cover with the 13 bolts and 2 nuts.

-

Fully tighten the 2 bolts A, then fully tighten the 2 nuts, then fully tighten the 11 bolts B.

Table 36. Text in Illustration *1 Nut 7.7 N*m 79 kgf*cm 68 in.*lbf

-

- Click here

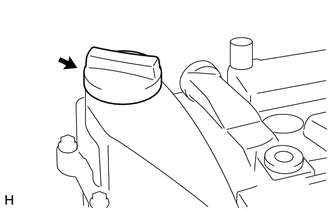

INSTALL OIL FILLER CAP SUB-ASSEMBLY

-

Install a new oil filler cap gasket to the oil filler cap.

-

Install the oil filler cap.

-

-

Click here

INSTALL OIL CONTROL VALVE FILTER

-

Install the oil control valve filter onto the tight plug.

Table 37. Text in Illustration *1 Oil Control Valve Filter *2 Gasket *3 Head Taper Screw Plug -

Install a new gasket and install the oil control valve filter using an 8 mm hexagon wrench.

Table 38. Text in Illustration *1 8 mm Hexagon Wrench 25 N*m 250 kgf*cm 18 ft.*lbf

-

-

Click here

INSTALL ENGINE OIL PRESSURE SWITCH ASSEMBLY

-

Apply adhesive to 2 or 3 threads of the oil pressure switch.

Table 39. Text in Illustration *1 Adhesive Adhesive Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent. -

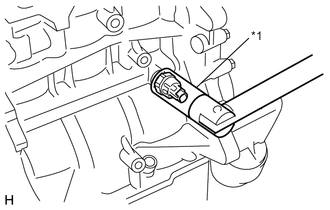

Using a 24 mm deep socket wrench, install the engine oil pressure switch.

Table 40. Text in Illustration *1 24 mm Deep Socket Wrench 15 N*m 153 kgf*cm 11 ft.*lbf Note:Do not start the engine for at least 1 hour after installation.

-

- Click here

INSTALL KNOCK SENSOR

-

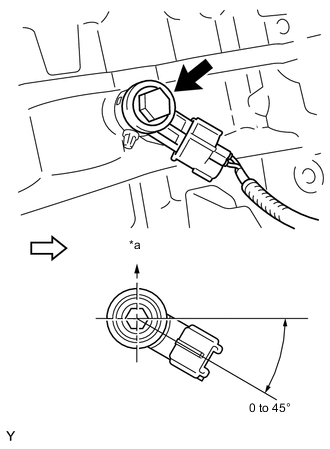

Install the knock sensor with the bolt as shown in the illustration.

Table 41. Text in Illustration *a Upper

Front of Engine 20 N*m 204 kgf*cm 15 ft.*lbf Note:

-

If a component has been dropped or subjected to a strong impact, replace it.

-

Make sure that each knock sensor is in the correct position.

-

-

-

Click here

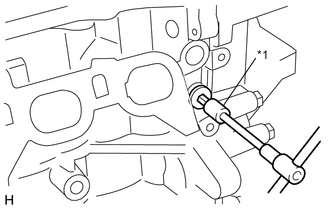

INSTALL CRANKSHAFT POSITION SENSOR

-

Apply a light coat of engine oil to the O-ring.

Note:If reusing the crankshaft position sensor, be sure to inspect the O-ring.

-

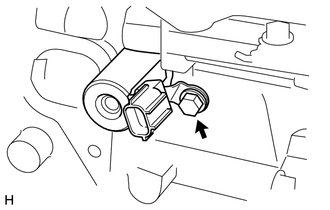

Install the crankshaft position sensor with the bolt.

7.5 N*m 76 kgf*cm 66 in.*lbf Note:

-

If a component has been dropped or subjected to a strong impact, replace it.

-

Make sure that the O-ring is not damaged or does not jump out of position during installation.

-

-

- Click here

INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY

-

Apply a light coat of engine oil to the O-ring.

Note:If reusing the camshaft timing oil control valve assembly, be sure to inspect the O-ring.

-

Install the camshaft timing oil control valve with the bolt.

10 N*m 102 kgf*cm 7 ft.*lbf Note:

-

If a component has been dropped or subjected to a strong impact, replace it.

-

Make sure that the O-ring is not damaged or does not jump out of position during installation.

-

-

-

Click here

INSTALL ENGINE COOLANT TEMPERATURE SENSOR

-

Install a new gasket to the engine coolant temperature sensor.

-

Using a 19 mm deep socket wrench, install the engine coolant temperature sensor.

Table 42. Text in Illustration *1 19 mm Deep Socket Wrench 20 N*m 200 kgf*cm 14 ft.*lbf

-

-

Click here

INSTALL CAMSHAFT POSITION SENSOR

-

Apply a light coat of engine oil to the O-ring.

Note:If reusing the camshaft position sensor, be sure to inspect the O-ring.

-

Install the camshaft position sensor with the bolt.

7.5 N*m 76 kgf*cm 66 in.*lbf Note:

-

If a component has been dropped or subjected to a strong impact, replace it.

-

Make sure that the O-ring is not damaged or does not jump out of position during installation.

-

-

- Click here

INSTALL SPARK PLUG