CYLINDER HEAD DISASSEMBLY

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed, installed, or replaced during the cylinder head sub-assembly disassembly/reassembly are shown below.

| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

| Auxiliary battery terminal is disconnected/reconnected | Memorize steering angle neutral point | LKA/LDA system | |

| Pre-collision system | |||

| Parking assist monitor system | |||

| Steering sensor zero point calibration | Variable gear ratio steering system | ||

| Replacement of ECM | Vehicle Identification Number (VIN) registration | DTC P063051 is output | w/ Canister Pump Module: Click here w/o Canister Pump Module: Click here |

|

Inspection after repair |

|

w/ Canister Pump Module: Click here w/o Canister Pump Module: Click here |

| Replacement of engine assembly | Inspection after repair | ||

| Drive learning*2 |

|

||

| Parts between the steering wheel and tires have been removed/installed, replaced or adjusted | Perform Actuator Angle Neutral Point Calibration and Initialization |

|

|

| Suspension, tires, etc*1 | Television camera assembly optical axis (Back camera position setting) | Parking assist monitor system |

*2: After performing the confirmation driving pattern, if the shock during acceleration is large after calibrating the "A/T Code Reset", perform driving learning.

PROCEDURE

-

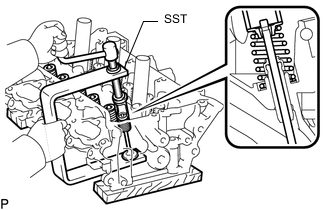

REMOVE INTAKE VALVE

-

Using SST, compress the inner compression spring and remove the valve spring retainer locks.

- SST

- 09202-70020 ( 09202-01010, 09202-01020 )

- 09202-00021

-

Remove the valve spring retainer, inner compression spring and intake valve.

Tech Tips

Arrange the removed parts in the correct order.

-

-

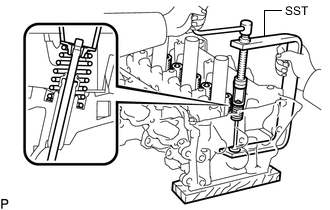

REMOVE EXHAUST VALVE

-

Using SST, compress the inner compression spring and remove the valve spring retainer locks.

- SST

- 09202-70020 ( 09202-01010, 09202-01020 )

- 09202-00021

-

Remove the valve spring retainer, inner compression spring and exhaust valve.

Tech Tips

Arrange the removed parts in the correct order.

-

-

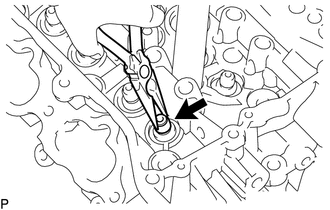

REMOVE VALVE STEM OIL SEAL

-

Using needle-nose pliers, remove the valve stem oil seals.

-

-

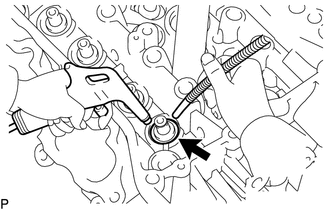

REMOVE VALVE SPRING SEAT

-

Using compressed air and a magnet hand, remove the valve spring seats by blowing air onto them.

-

-

REMOVE NO. 1 STRAIGHT SCREW PLUG

Note

If water leaks from a straight screw plug or the plug is corroded, replace it.

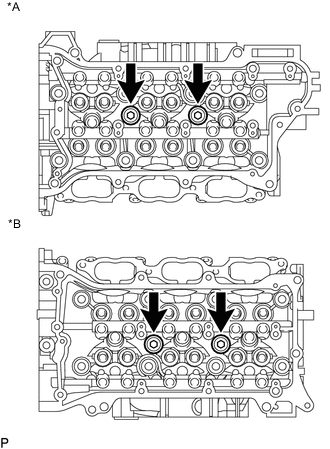

*A for Bank 1 *B for Bank 2

-

Using a 10 mm hexagon wrench, remove the 4 No. 1 straight screw plugs and 4 gaskets.

-

-

REMOVE NO. 2 STRAIGHT SCREW PLUG

Note

If water leaks from a straight screw plug or the plug is corroded, replace it.

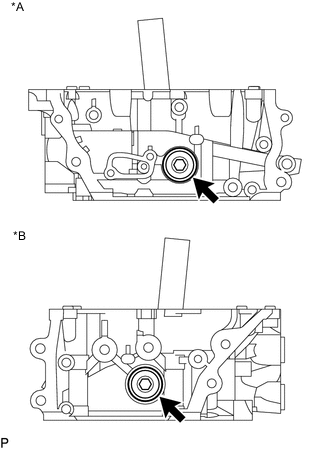

*A for Bank 1 *B for Bank 2

-

Using a 14 mm hexagon wrench, remove the 2 No. 2 straight screw plugs and 2 gaskets.

-

-

REMOVE NO. 3 STRAIGHT SCREW PLUG

Note

If water leaks from a straight screw plug or the plug is corroded, replace it.

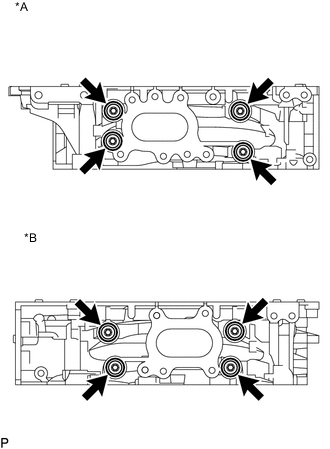

*A for Bank 1 *B for Bank 2

-

Using a 10 mm hexagon wrench, remove the 8 No. 3 straight screw plugs and 8 gaskets.

-

-

REMOVE UNION

Note

It is not necessary to remove the union unless it is being replaced.

-

REMOVE STUD BOLT

Note

If the stud bolt is deformed or the threads are damaged, replace it.