MOTOR GENERATOR CONTROL SYSTEM, Diagnostic DTC:P0C3D1C

| DTC Code | DTC Name |

|---|---|

| P0C3D1C | DC/DC Converter Temperature Sensor "B" Circuit Voltage Out of Range |

DTC SUMMARY

-

MALFUNCTION DESCRIPTION

These DTCs indicate that the boost converter temperature sensor (lower) value is abnormal. The cause of this malfunction may be one of the following:

-

Inverter with converter assembly internal circuit malfunction

Internal inverter malfunction

-

Coolant circulation abnormal (frozen or leaking, etc.)

Hybrid cooling system malfunction

-

The connectors are not connected properly

Inverter low-voltage circuit malfunction

-

DESCRIPTION

The motor generator control ECU, which is built into in the inverter with converter assembly, detects the temperature of the boost converter using a temperature sensor built into the boost converter. If necessary, the motor generator control ECU will limit inverter output to help prevent the boost converter from overheating. The motor generator control ECU also detects malfunctions in the sensor based on the temperature sensor values.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | MIL | Warning Indicate |

|---|---|---|---|---|---|

| P0C3D1C | DC/DC Converter Temperature Sensor "B" Circuit Voltage Out of Range | The actual boost converter temperature (lower) high and the difference between the estimated boost converter temperature (lower) and the actual temperature exceeds a threshold for 10 seconds. Additionally, when no other temperature deviations are present, the boost converter temperature (lower) sensor value differs from the values of other sensors. (1 trip detection logic) |

|

Comes on | Master Warning Light: Comes on |

| DTC No. | Data List |

|---|---|

| P0C3D1C |

|

CONFIRMATION DRIVING PATTERN

Tech Tips

After repair has been completed, clear the DTC and then check that the vehicle has returned to normal by performing the following All Readiness check procedure.

-

Connect the GTS to the DLC3.

-

Turn the power switch on (IG) and turn the GTS on.

-

Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

-

Turn the power switch off and wait for 2 minutes or more.

-

Turn the power switch on (IG) and turn the GTS on.

-

Turn the power switch on (READY) and wait for 90 seconds or more by EV mode.

Tech Tips

Check that there are no abnormalities (abnormal sounds, coolant leaks, DTC output, etc.).

-

Drive the vehicle for approximately 10 minutes while following data list is above 25°C (77°F): "Inverter Coolant Temperature".

-

Enter the following menus: Powertrain / Motor Generator / Utility / All Readiness.

-

Check the DTC judgment result.

Tech Tips

-

If the judgment result shows NORMAL, the system is normal.

-

If the judgment result shows ABNORMAL, the system has a malfunction.

-

If the judgment result shows INCOMPLETE or N/A, perform the normal judgment procedure again.

-

CAUTION / NOTICE / HINT

CAUTION:

-

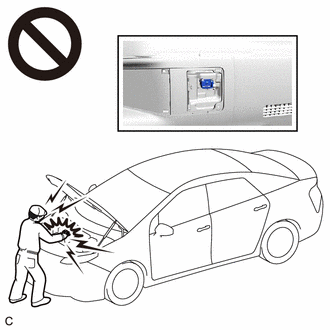

Before the following operations are conducted, take precautions to prevent electric shock by turning the power switch off, wearing insulated gloves, and removing the service plug grip from HV battery.

-

Inspecting the high-voltage system

-

Disconnecting the low voltage connector of the inverter with converter assembly

-

Disconnecting the low voltage connector of the HV battery

-

To prevent electric shock, make sure to remove the service plug grip to cut off the high voltage circuit before servicing the vehicle.

-

After removing the service plug grip from the HV battery, put it in your pocket to prevent other technicians from accidentally reconnecting it while you are working on the high-voltage system.

-

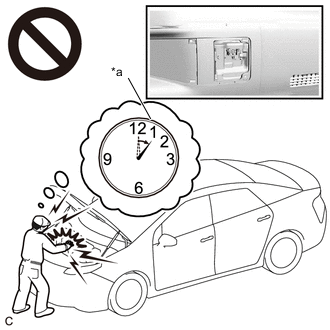

*a Without waiting for 10 minutes After removing the service plug grip, wait for at least 10 minutes before touching any of the high-voltage connectors or terminals. After waiting for 10 minutes, check the voltage at the terminals in the inspection point in the inverter with converter assembly. The voltage should be 0 V before beginning work.

Tech Tips

Waiting for at least 10 minutes is required to discharge the high-voltage capacitor inside the inverter with converter assembly.

Note

After turning the power switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notices before proceeding with work.

PROCEDURE

-

CHECK DTC OUTPUT (HYBRID CONTROL)

-

Connect the GTS to the DLC3.

-

Turn the power switch on (IG).

-

Enter the following menus: Powertrain / Hybrid Control / Trouble Codes.

-

Check for DTCs.

Powertrain > Hybrid Control > Trouble CodesResult Result Proceed to P0C3D1C only is output, or DTCs except the ones in the table below are also output. A Any of the following DTCs are also output. B Table 1 Malfunction Content Relevant DTC Insulation Malfunction P1C7C49 Hybrid/EV Battery Voltage System Isolation (A/C Area) Internal Electronic Failure P1C7D49 Hybrid/EV Battery Voltage System Isolation (Hybrid/EV Battery Area) Internal Electronic Failure P1C7E49 Hybrid/EV Battery Voltage System Isolation (Transaxle Area) Internal Electronic Failure P1C7F49 Hybrid/EV Battery Voltage System Isolation (Direct Current Area) Internal Electronic Failure Table 2 Malfunction Content Relevant DTC Sensor and actuator circuit malfunction P0C7396 Motor Electronics Coolant Pump "A" Component Internal Failure P314A31 Motor Electronics Coolant Pump "A" No Signal System malfunction P0A9300 Inverter "A" Cooling System Performance Tech Tips

P0C3D1C may be output as a result of the malfunction indicated by the DTCs above.

-

The chart above is listed in inspection order of priority.

-

Check DTCs that are output at the same time by following the listed order. (The main cause of the malfunction can be determined without performing unnecessary inspections.)

-

-

Turn the power switch off.

B

GO TO DTC CHART (HYBRID CONTROL SYSTEM) Click here

A

-

-

CHECK CONNECTOR CONNECTION CONDITION (INVERTER WITH CONVERTER ASSEMBLY CONNECTOR)

Result Result Proceed to OK A NG (The connector is not connected securely.) B NG (The terminals are not making secure contact or are deformed, or water or foreign matter exists in the connector.) C CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Check the connection condition of the low voltage connectors of the inverter with converter assembly and the contact pressure of each terminal. Check the terminals for deformation, and the connector for water and foreign matter.

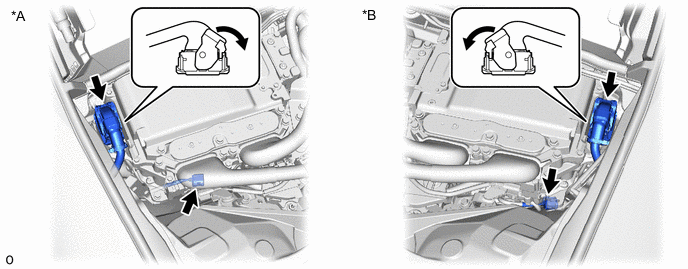

*A for LHD *B for RHD Note

Before disconnecting the connector, confirm that it is properly connected by checking that the claws of the lock levers are engaged and that the connector cannot be pulled off.

OK - The connector is connected securely. - The terminals are not deformed and are connected securely. - No water or foreign matter in the connector. Result Result Proceed to OK A NG (The connector is not connected securely.) B NG (The terminals are not making secure contact or are deformed, or water or foreign matter exists in the connector.) C Tech Tips

When connecting the connector, connect it with the lock levers raised. Rotate each lock lever downward and make sure that the connector is securely connected. When a lock lever is fully lowered, a click will be heard as its claw engages. After the click is heard, pull up on the connector to confirm that it is securely connected.

B

CONNECT SECURELY

C

REPAIR OR REPLACE HARNESS OR CONNECTOR

A

-

-

CHECK COOLING SYSTEM

Tech Tips

If the "Cooling System" inspection results are normal, perform the next step.

Result Proceed to NEXT

NEXT

REPLACE INVERTER WITH CONVERTER ASSEMBLY Click here