EMISSION CONTROL SYSTEM

-

FUNCTION OF MAIN COMPONENTS

-

The main components of the 2AR-FE emission control system are as follows:

Component Function TWC Oxidizes CO and HC in the exhaust gas and deoxidizes NOx at the same time, to purify them into CO2, H2O and N2. Air Fuel Ratio Sensor Is used to determine the concentration of oxygen remaining in the exhaust gas. Has a characteristic where its output is proportional to the engine air fuel ratio. Located upstream of the catalytic converter. For details Click here.

Oxygen Sensor The signal of the air fuel ratio sensor changes abruptly between lean and rich at the stoichiometric air fuel ratio. Located downstream of the catalytic converter. For details Click here.

ECM Controls the volume of fuel consumed based primarily on the signal from the air fuel ratio sensor, with minor corrections based on the signal from the oxygen sensor. This control optimizes the exhaust emissions. Charcoal Canister Contains activated charcoal to absorb the fuel vapor that is created in the fuel tank assembly. Fresh Air Line Fresh air goes into the charcoal canister and the cleaned drain air goes out into the atmosphere. Purge VSV Opens in accordance with the signals from the ECM when the system is purging, in order to send the fuel vapor that was absorbed by the charcoal canister into the intake manifold. In system monitoring mode, this valve controls the introduction of vacuum into the fuel tank assembly. Canister Filter Prevents dust and debris in the fresh air from entering the system.

-

-

CONSTRUCTION

-

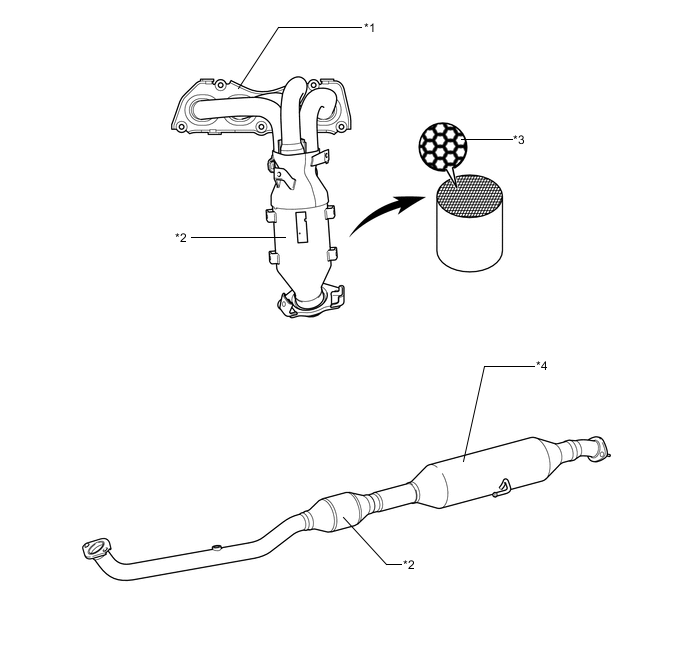

Three-Way Catalytic Converter (TWC)

-

TWCs are provided in the exhaust manifold sub-assembly and also in the front exhaust pipe assembly.

-

An exhaust manifold with an integrated TWC is used for warm-up of the TWC in the front exhaust pipe assembly.

-

An ultra thin-wall, high-cell density, ceramic type TWC is used for the exhaust manifold sub-assembly and a thin-wall, ceramic type TWC is used for the front exhaust pipe assembly.

-

The ultra thin-wall TWC enables improved exhaust emissions through optimized cell density and wall thickness.

Text in Illustration *1 Exhaust Manifold Sub-assembly *2 TWC *3 Ultra Thin-wall *4 Front Exhaust Pipe Assembly

-

-

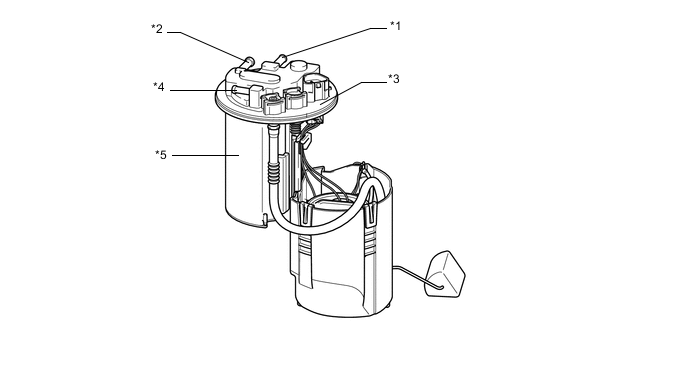

Charcoal Canister

-

The charcoal canister is integrated into the fuel suction tube with pump and gauge assembly.

Text in Illustration *1 Fresh Air Port *2 EVAP Port (from Fuel Tank Assembly) *3 Fuel Suction Tube with Pump and Gauge Assembly *4 Purge Port (to Intake Manifold) *5 Charcoal Canister - -

-

-

-

OPERATION

-

Evaporative Emission Control System

-

Based on the signals from various sensors, the ECM opens and closes the purge VSV. Thus, it controls the purge flow of evaporative emissions (HC) in the charcoal canister in accordance with the engine conditions.

-

-