ENGINE UNIT

-

CONSTRUCTION

-

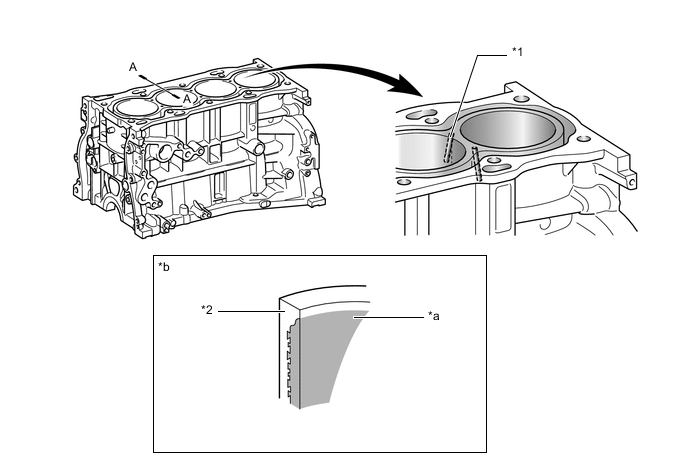

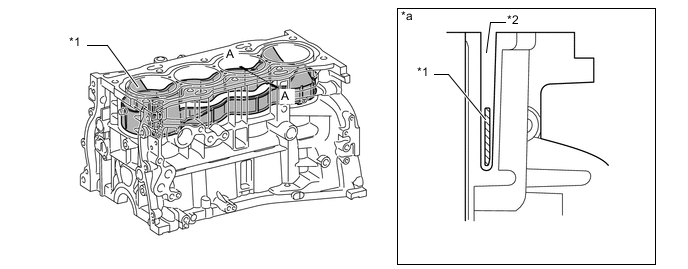

The cylinder block sub-assembly is made of aluminum alloy, so it is lightweight.

-

Water passages have been provided between the cylinder bores. By allowing the engine coolant to flow between the cylinder bores, this construction enables the temperature of the cylinder walls to be kept uniform.

-

The liners are a spiny-type, which have been manufactured so that their cast outers form large irregular surfaces in order to enhance the adhesion between the liners and the aluminum cylinder block sub-assembly. The enhanced adhesion helps heat dissipation, resulting in a lower overall temperature and reduced heat deformation of the cylinder bores.

*1 Water Passage *2 Cylinder Block Sub-assembly *a Spiny-type Liner (Irregularly Shaped Outer Cast Surface of Liner) *b A-A Cross Section -

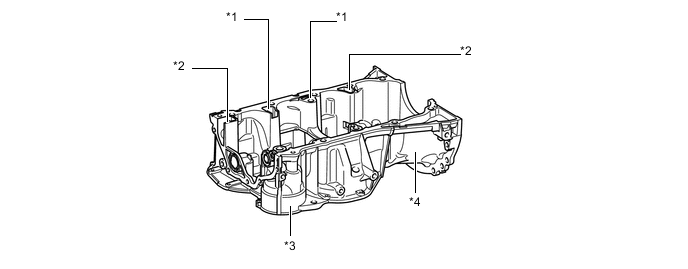

Blowby gas passages are provided in the stiffening crankcase assembly.

-

Oil drain passages are provided in the stiffening crankcase assembly. This prevents the crankshaft from churning the engine oil, reducing rotational resistance.

-

The oil filter bracket is integrated into the stiffening crankcase assembly.

*1 Blowby Gas Passage *2 Oil Drain Passage *3 Oil Filter Bracket *4 Stiffening Crankcase Assembly -

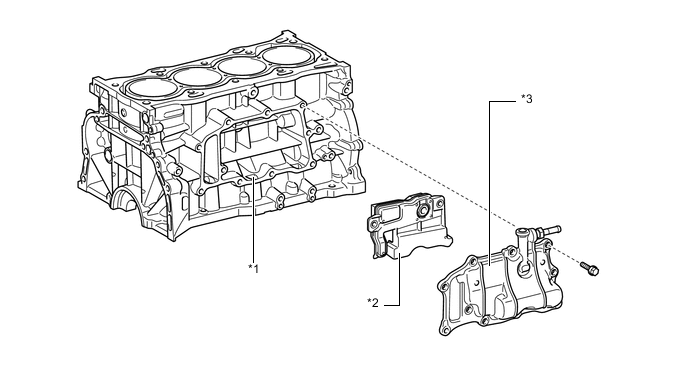

An oil separator is provided in the blow-by gas passage inside the cylinder block sub-assembly. This separates the engine oil from the blow-by gas in order to reduce oil degradation and reduce the amount of engine oil consumed.

*1 Oil Separator *2 Case Separator *3 Ventilation Case Sub-assembly - - -

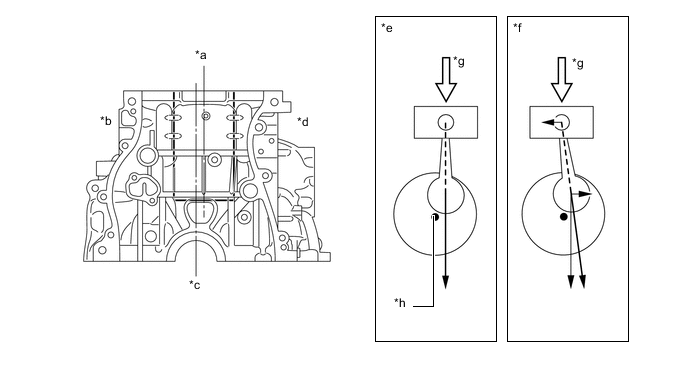

Through the use of an offset crankshaft, the centerline of the bores is shifted 10 mm (0.394 in.) towards the exhaust side in relation to the centerline of the crankshaft. Thus, the side force to the cylinder wall is reduced when the maximum pressure is applied. This contributes to fuel economy.

*a Bore Center *b Intake Side *c Crankshaft Center *d Exhaust Side *e Offset Crankshaft *f Center Crankshaft *g Maximum Pressure *h Crankshaft Center -

A shallow bottom water jacket is used. The resulting reduction in the volume of the engine coolant improves warm-up performance, which contributes to improved fuel economy.

-

A water jacket spacer is provided in the water jacket of the cylinder block sub-assembly.

-

The water jacket spacer suppresses the water flow in the bottom of the water jackets, guides the coolant in the upper area of the water jacket, and ensures uniform temperature distribution. As a result, the viscosity of the engine oil that acts as a lubricant between the bore walls and the pistons can be lowered, thus reducing friction.

*1 Cylinder Block Water Jacket Spacer *2 Water Jacket *a A-A Cross Section - -

-