SEAT BELT WARNING SYSTEM(w/o Occupant Classification System) Driver Side Seat Belt Warning Light does not Operate

| DTC Code | DTC Name |

|---|---|

| Driver Side Seat Belt Warning Light does not Operate |

DESCRIPTION

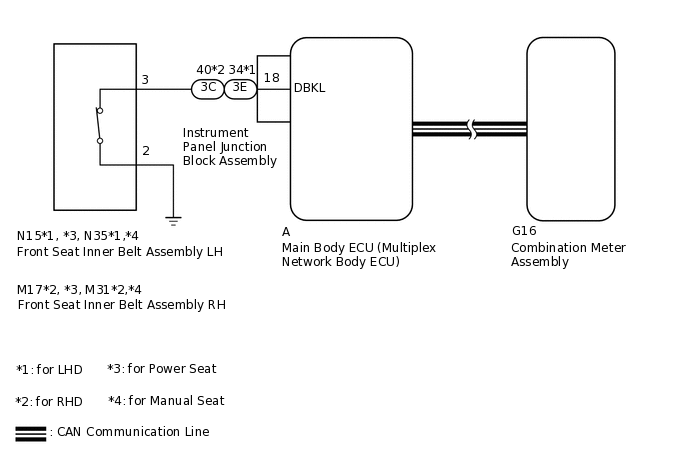

When the ignition switch is turned to ON, the main body ECU (multiplex network body ECU) transmits front seat inner belt LH*1 (or RH*2) state signals to the combination meter assembly through the CAN. If the driver side seat belt is not fastened, the combination meter assembly blinks the front seat belt warning light. If the seat belt is fastened, the warning light goes off.

*1: for LHD

*2: for RHD

The front seat belt warning light on the combination meter assembly is used for both the driver side seat and front passenger side seat.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

The seat belt warning system uses a CAN communication system. Inspect the communication function by following How to Proceed with troubleshooting.

Troubleshoot the seat belt warning system after confirming that the communication system is functioning properly.

PROCEDURE

READ VALUE USING GTS (D SEAT BELT BUCKLE SWITCH)

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Enter the following menus: Body Electrical / Main Body / Data List.

Read the Data List according to the display on the GTS.

Body Electrical > Main Body > Data List

Tester Display

Measurement Item

Range

Normal Condition

Diagnostic Note

D Seat Buckle SW

Driver side seat belt buckle switch

ON/OFF

ON: Driver side seat belt fastened

OFF: Driver side seat belt unfastened

-

Body Electrical > Main Body > Data List

Tester Display

D Seat Buckle SW

Result

Result

Proceed to

ON or OFF is displayed on the GTS screen according to the driver side seat belt condition

A

ON or OFF is not displayed normally on the GTS screen according to the driver side seat belt condition

B

B INSPECT FRONT SEAT INNER BELT ASSEMBLYClick here

PERFORM ACTIVE TEST USING GTS (DRIVER SIDE SEAT BELT)

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Enter the following menus: Body Electrical / Combination Meter / Active Test.

Perform the Active Test according to the display on the GTS.

Body Electrical > Combination Meter > Active Test

Tester Display

Measurement Item

Control Range

Diagnostic Note

Driver Side Seat Belt

Front seat belt warning light

OFF/ON

The current customize setting is displayed.

Body Electrical > Combination Meter > Active Test

Tester Display

Driver Side Seat Belt

OK

The front seat belt warning light on the combination meter assembly operates normally.

Result

Proceed to

OK

NG

INSPECT FRONT SEAT INNER BELT ASSEMBLY

Remove the front seat inner belt assembly.

Inspect the front seat inner belt assembly.

Result

Proceed to

OK

NG

CHECK HARNESS AND CONNECTOR (FRONT SEAT INNER BELT ASSEMBLY - MAIN BODY ECU [MULTIPLEX NETWORK BODY ECU] AND BODY GROUND)

Disconnect the N15*1,*3, N35*1,*4, M17*2,*3 or M31*2,*4 front seat inner belt assembly connector.

*1: for LHD

*2: for RHD

*3: for Power Seat

*4: for Manual Seat

Disconnect the A main body ECU (multiplex network body ECU) connector.

Measure the resistance according to the value(s) in the table below.

Standard Resistance

for LHD, for Power Seat

Tester Connection

Condition

Specified Condition

N15-3 - A-18 (DBKL)

Always

Below 1 Ω

N15-2 - Body ground

N15-3 - Body ground

Always

10 kΩ or higher

for LHD, for Manual Seat

Tester Connection

Condition

Specified Condition

N35-3 - A-18 (DBKL)

Always

Below 1 Ω

N35-2 - Body ground

N35-3 - Body ground

Always

10 kΩ or higher

for RHD, for Power Seat

Tester Connection

Condition

Specified Condition

M17-3 - A-18 (DBKL)

Always

Below 1 Ω

M17-2 - Body ground

M17-3 - Body ground

Always

10 kΩ or higher

for RHD, for Manual Seat

Tester Connection

Condition

Specified Condition

M31-3 - A-18 (DBKL)

Always

Below 1 Ω

M31-2 - Body ground

M31-3 - Body ground

Always

10 kΩ or higher

Result

Proceed to

OK

NG

OK REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)

CHECK HARNESS AND CONNECTOR (FRONT SEAT INNER BELT ASSEMBLY - INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY)

Disconnect the N15*1,*3, N35*1,*4, M17*2,*3 or M31*2,*4 front seat inner belt assembly connector.

*1: for LHD

*2: for RHD

*3: for Power Seat

*4: for Manual Seat

Disconnect the 3E*1 or 3C*2 instrument panel junction block assembly connector.

Measure the resistance according to the value(s) in the table below.

Standard Resistance

for LHD, for Power Seat

Tester Connection

Condition

Specified Condition

N15-3 - 3E-34 (DBKL)

Always

Below 1 Ω

for LHD, for Manual Seat

Tester Connection

Condition

Specified Condition

N35-3 - 3E-34 (DBKL)

Always

Below 1 Ω

for RHD, for Power Seat

Tester Connection

Condition

Specified Condition

M17-3 - 3C-40 (DBKL)

Always

Below 1 Ω

for RHD, for Manual Seat

Tester Connection

Condition

Specified Condition

M31-3 - 3C-40 (DBKL)

Always

Below 1 Ω

Result

Proceed to

OK

NG

OK INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY

NG REPAIR OR REPLACE HARNESS OR CONNECTOR