CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM, Diagnostic DTC:P0712, P0713

| DTC Code | DTC Name |

|---|---|

| P0712 | Transmission Fluid Temperature Sensor "A" Circuit Low Input |

| P0713 | Transmission Fluid Temperature Sensor "A" Circuit High Input |

DESCRIPTION

The CVT fluid temperature sensor converts the fluid temperature into a resistance value which is detected by the ECM.

The sensor resistance changes with the CVT fluid temperature. As the temperature rises, the sensor resistance decreases. The ECM applies voltage to the temperature sensor through ECM terminal THO1 and calculates the fluid temperature based on the voltage signal.

Tech Tips

The CVT fluid temperature is likely to increase under conditions such as towing, climbing hills and in traffic.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | MIL | Memory |

|---|---|---|---|---|---|

| P0712 | Transmission Fluid Temperature Sensor "A" Circuit Low Input | There is a short in the CVT fluid temperature sensor circuit for 0.5 seconds (1 trip detection logic). |

|

Comes on | DTC stored |

| P0713 | Transmission Fluid Temperature Sensor "A" Circuit High Input | Either one of the following conditions is met (1 trip detection logic):

|

|

Comes on | DTC stored |

MONITOR DESCRIPTION

The CVT fluid temperature sensor converts the CVT fluid temperature to an electrical resistance value. Based on the resistance, the ECM determines the CVT fluid temperature and detects an open or short circuit in the CVT fluid temperature circuit. If the resistance value of the CVT fluid temperature is below 79 Ω*1 or higher than 156 kΩ*2, the ECM interprets this as a fault in the CVT fluid sensor or wiring. The ECM illuminates the MIL and stores a DTC.

*1: 150°C (302°F) or higher is indicated regardless of the actual CVT fluid temperature.

*2: -40°C (-40°F) is indicated regardless of the actual CVT fluid temperature.

Tech Tips

The CVT fluid temperature can be checked on the GTS display.

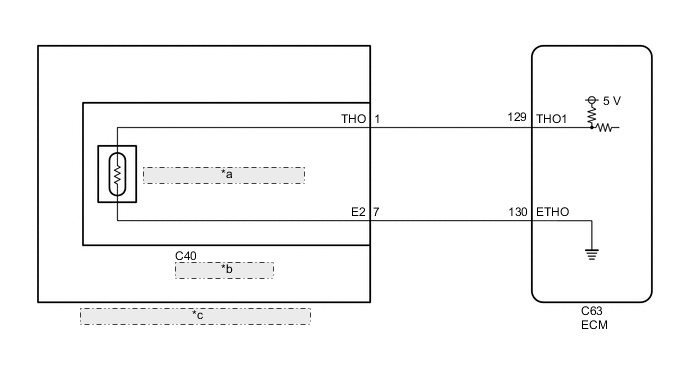

WIRING DIAGRAM

| *a | CVT Fluid Temperature Sensor |

| *b | Transmission Wire |

| *c | Continuously Variable Transaxle Assembly |

CAUTION / NOTICE / HINT

Note

-

Perform initialization when parts related to the continuously variable transaxle are replaced.

-

Check that no DTCs are stored after performing initialization.

Tech Tips

After performing repair, clear the DTCs and perform the following procedure to check that DTCs are not output.

-

Start the engine and wait for 15 minutes or more.

-

Check for DTCs again.

PROCEDURE

-

READ VALUE USING GTS (A/T OIL TEMPERATURE 1)

-

Warm up the engine.

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Data List.

Powertrain > Engine and ECT > Data ListTester Display A/T Oil Temperature 1 -

In accordance with the display on the GTS, read the Data List.

Powertrain > Engine and ECT > Data ListTester Display Measurement Item Range Normal Condition Diagnostic Note A/T Oil Temperature 1 CVT fluid temperature sensor value Min.: -40°C (-40°F)

Max.: 150°C (302°F)

-

After stall speed test: approximately 100°C (212°F)

-

Equal to ambient temperature after cold soak

If the value is -40°C (-40°F) or 150°C (302°F) or higher, the CVT fluid temperature sensor circuit is open or shorted. Result Result Proceed to Data display is not within Normal Condition range A Data display is within Normal Condition range B -

B

REPLACE ECM Click here

A

-

-

INSPECT TRANSMISSION WIRE (CVT FLUID TEMPERATURE SENSOR)

-

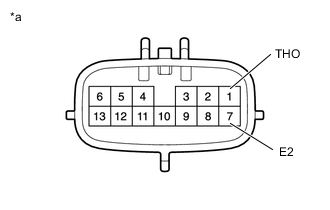

*a Component without harness connected

(Transmission Wire)

Disconnect the C40 transmission wire connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition 1 (THO) - 7 (E2) Always 79 Ω to 156 kΩ 1 (THO) - Body ground and other terminals Always 10 kΩ or higher 7 (E2) - Body ground and other terminals Always 10 kΩ or higher Tech Tips

If the resistance is outside the specified range at any of the CVT fluid temperatures shown in the table below, the driveability of the vehicle may be affected.

CVT Fluid Temperature Specified Condition 10°C (50°F) 5.6 to 7.3 kΩ 25°C (77°F) 3.5 kΩ 110°C (230°F) 0.22 to 0.27 kΩ Result Proceed to OK NG

NG

REPLACE CONTINUOUSLY VARIABLE TRANSAXLE ASSEMBLY Click here

OK

-

-

CHECK HARNESS AND CONNECTOR (TRANSMISSION WIRE - ECM)

-

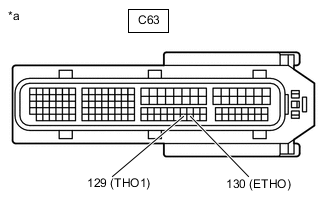

*a Front view of wire harness connector

(to ECM)

Disconnect the ECM connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition C63-129 (THO1) - C63-130 (ETHO) Always 79 Ω to 156 kΩ C63-129 (THO1) - Body ground and other terminals Always 10 kΩ or higher C63-130 (ETHO) - Body ground and other terminals Always 10 kΩ or higher Result Proceed to OK NG

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR (TRANSMISSION WIRE - ECM)

OK

-

-

REPLACE ECM

-

Replace the ECM.

Result Proceed to NEXT

NEXT

PERFORM INITIALIZATION Click here

-

-

REPLACE CONTINUOUSLY VARIABLE TRANSAXLE ASSEMBLY

-

Replace the continuously variable transaxle assembly.

-

When Not Using the Engine Support Bridge

-

When Using the Engine Support Bridge

Result Proceed to NEXT -

NEXT

PERFORM INITIALIZATION Click here

-

-

REPLACE ECM

-

Replace the ECM.

Result Proceed to NEXT

NEXT

PERFORM INITIALIZATION Click here

-