COMPRESSOR(for 2AR-FE) REASSEMBLY

PROCEDURE

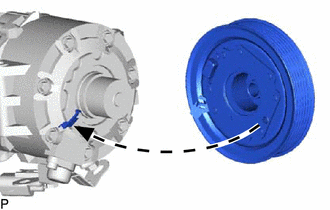

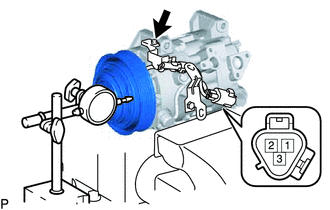

INSTALL MAGNET CLUTCH ASSEMBLY

-

Install the magnet clutch stator with the parts aligned as shown in the illustration.

-

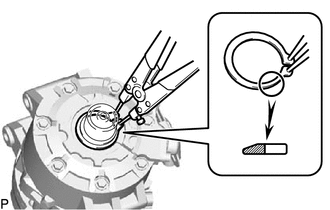

Using a snap ring expander, install a new snap ring with the chamfered side facing outward.

Attach the connector clamp.

-

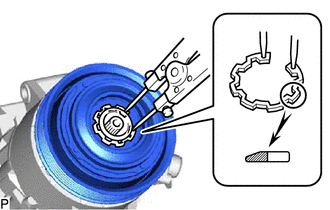

Install the magnet clutch rotor, and then using a snap ring expander, install a new snap ring with the chamfered side outward.

Note:Do not damage the seal cover of the bearing when installing the snap ring.

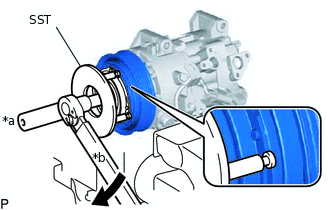

Install the compressor washer(s) and magnet clutch hub.

Note:Do not change the combination of the compressor washer(s) used before disassembly.

-

*a

Hold

*b

Turn

Using SST, hold the magnet clutch hub and install the bolt.

09985-00270

18 N*m

184 kgf*cm

13 ft.*lbf

Note:Make sure that there is no foreign matter or oil on the compressor shaft, bolt, and clutch hub.

-

INSTALL COOLER COMPRESSOR BRACKET

Install the cooler compressor bracket with the screw.

Attach the connector clamp.

Connect the connector.

INSPECT MAGNET CLUTCH CLEARANCE

-

Clamp the cooler compressor in a vise between aluminum plates.

Set the dial indicator to the magnet clutch hub as shown in the illustration.

Connect the battery positive (+) lead to terminal 3 of the magnet clutch connector and the negative (-) lead to the ground wire. Turn the magnet clutch on and off and measure the clearance.

Standard clearance

0.3 to 0.55 mm (0.0119 to 0.0216 in.)

If the measured value is not within the standard clearance, remove the magnet clutch hub and adjust the clearance using magnet clutch washers to obtain the standard clearance.

Magnet clutch washer thickness

0.1 mm (0.00394 in.)

0.3 mm (0.0118 in.)

0.5 mm (0.0197 in.)

Note:Adjustment should be performed with 3 or fewer magnet clutch washers.

Remove the cooler compressor from the vise.

-